+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

Additives improve efficiencies, cost savings

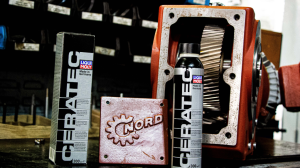

RELIABLE CERA TEC Various sectors can benefit from the ability of Cera Tec to protect the engine, transmission and gears from wear

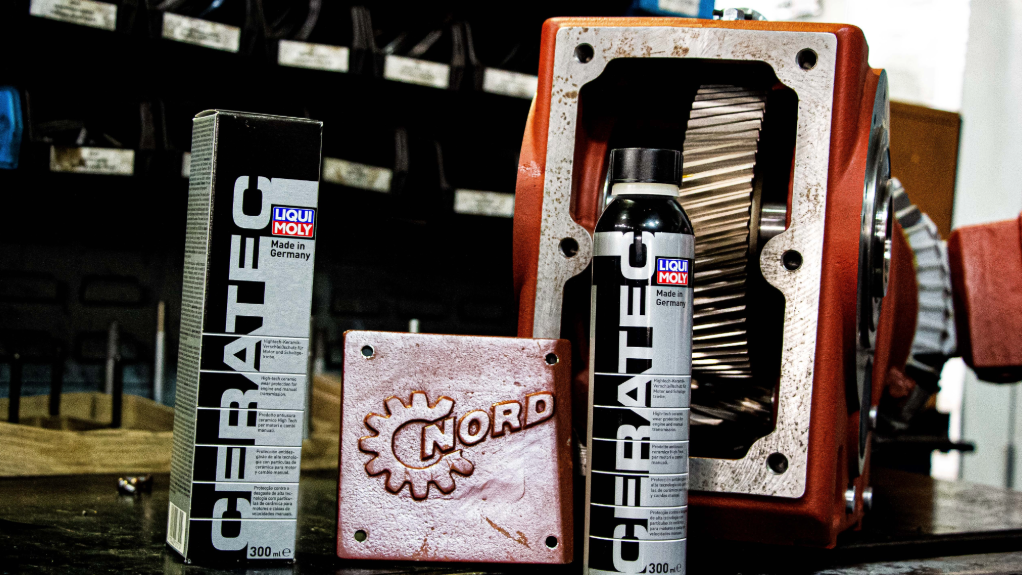

OPTIMAL LUBRICATION By using the Cera Tec and the Diesel Supper Additive products, companies can ensure effective wear resistance and corrosion protection for equipment and machinery

A major challenge that industrial equipment and services supplier BMG frequently encounters during site visits is the adverse impact of the procurement of low-cost oils, with BMG agricultural, automotive and lubrication division business development manager Carlo Beukes noting that this “cost-cutting” measure often results in reduced efficiency, accelerated internal wear and inflated repair costs.

“Proper lubrication, with the right oils and additives, is essential for ensuring the efficiency and longevity of machinery and equipment. High-quality lubricants, oils and greases not only extend the service life of engines and machinery, but also significantly enhance the performance of critical components, like bearings and industrial gearboxes,” says Beukes.

Fortunately, BMG supplies and supports a variety of Liqui Moly additives, oils and lubricants, which have been developed to enhance efficiencies in many industries. Typical applications include fleet and commercial vehicles and long-haul trucks, as well as heavy-duty machinery used in mining and quarrying, freight, automotive, general engineering, shipping, construction and agriculture.

BMG’s high-performance Liqui Moly oil additives comprise Cera Tec 3721 LM and Bakkie Series Oil Treatment 21456 LM. Included in the range of diesel additives are Diesel Purge 2520 LM, Diesel Particulate Protector 7180 LM, Anti-Bacterial Diesel 21317 LM and Super Diesel 8366 LM.

Liqui Moly Cera Tec additives have “exceptional resistance” to elevated temperature and pressure levels and are highly effective in protecting gears in industrial transmissions in many sectors, including sugar mills, mining, chemical plants, manufacturing and general engineering.

Cera Tec is a micro-ceramic solid lubricant suspension based on hexagonal boron nitride in selected base oils. It reduces friction and protects the engine and transmission against wear, thereby extending service life of assemblies. It also improves reliability of industrial equipment, lowers engine and transmission noise, minimises maintenance requirements and reduces downtime. Other benefits include energy savings, reduced risk of contamination, lower pollutant emissions and more efficient operating costs.

According to BMG specialists, the inclusion of Cera Tec additives in transmission oil enables a reduction in the temperature of the oil by up to 20 °C. This not only offers improved protection for machines, but also reduces the risk of malfunctions and lowers maintenance costs, says Beukes.

Liqui Moly Bakkie Series Oil Treatment 21456 LM, meanwhile, is suitable for use with all standard motor oils in gasoline and diesel engines, offering “optimal” engine wear protection, increased operational reliability, low noise levels and reduced oil and fuel consumption. The molybdenum disulphide in the oil forms a highly resistant lubricating film on all surfaces, which reduces friction and engine wear and ensures smooth operation.

Beukes notes that Liqui Moly Diesel Purge 2520 LM “efficiently” removes deposits on injection nozzles and in the combustion chamber, boosting the cetane number to increase operational reliability. It cleans the fuel system and protects against corrosion. It also “guarantees optimum combustion and eliminates engine operation problems”, including knocking in idle, ensuring quiet engine running.

Moreover, Liqui Moly Diesel Particulate Filter Protector 7180 LM was developed to ensure “optimum fuel combustion” to reduce soot formation, lower emissions and extend the service life of diesel particulate filters.

Vehicles used for short trips and in city traffic are especially affected by clogged diesel particulate filters and BMG specialists advise that the regular use of this additive will keep the diesel particulate filter clean, reducing costly repairs and preventing downtime.

The diesel particulate filters are suitable for diesel vehicles with particle filters, provided these are not already equipped with an electronically-controlled additive tank system for filter regeneration.

Liqui Moly Anti-Bacterial Diesel Additive 21317 LM is a highly effective biocide that protects against bacteria, yeasts and moulds in diesel-powered vehicles that have been decommissioned for a long period or are in low use. This additive is recommended for preventive use in construction machinery, commercial vehicles, motor homes, passenger cars and storage tankers, as well as for sterilising already infested tank systems.

Liqui Moly’s Super Diesel Additive 8366 LM – which has been specially formulated for modern engines, fuels and demanding running conditions – contains a mixture of agents with cleaning, dispersing, material-protection and cetane-number-increasing properties.

Finally, the Super Diesel Additive, which offers high wear resistance and corrosion protection, has also been formulated to boost the cetane number and to clean the entire injection system, by preventing the build-up of deposits and maintaining clean injection nozzles. It improves cold-start properties, reduces injector failures, ensures smooth operation and reduces the risk of engine failures from oil dilution.

The injection pumps and injectors in “state-of-the-art” engines, with high system pressures and tight-fitting tolerances, are lubricated only by diesel fuel. However, sulphur-free or contaminated diesel fuels cannot always ensure the required lubrication. The effective combination of lubrication improvers such as Super Diesel Additive optimises the lubricating characteristics of the fuel, protecting the sensitive components in the fuel system.

Through BMG’s range of energy efficient products – which includes synthetic oils, lubricants and bespoke lubrication systems – and the support of a technically competent team, the company ensures efficient maintenance, extended life of components and energy savings at every plant.