+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

Advanced materials enhance reliability of scraper chains – supplier

IMPROVED RELIABILITY The transition from the previous-generation material has been driven by BMG's commitment to performance, advanced materials, the latest technologies and long-term value for customers

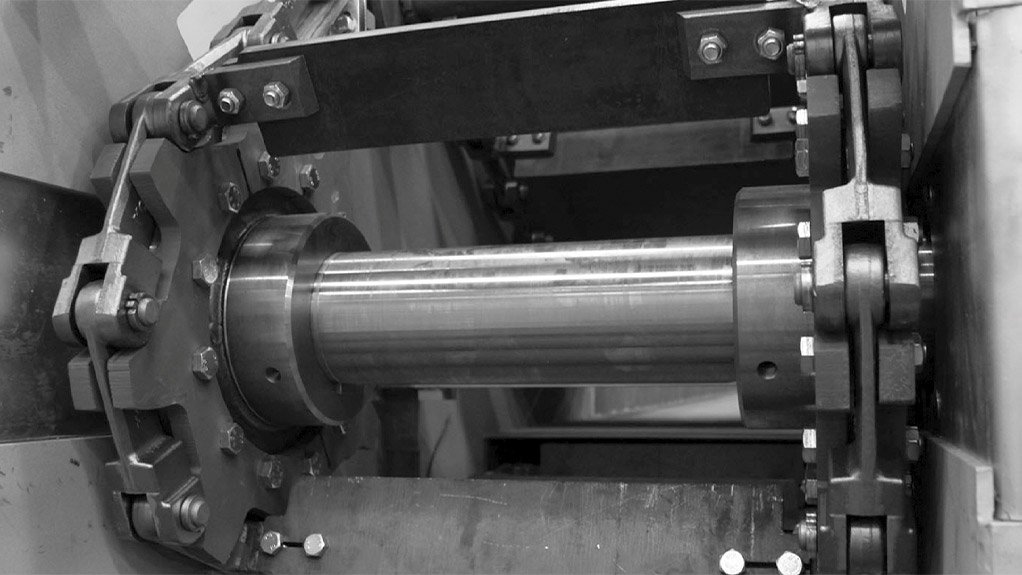

Industrial equipment supplier BMG’s power transmission division recently launched a new generation of Fenner scraper chain – now manufactured in more durable, advanced materials to ensure the highest possible performance in many sectors, including boiler and burner applications.

“These new Fenner scraper chain links are precision-engineered and forged from a high-performance alloy, representing a notable advancement in both strength and reliability,” BMG power transmission division business unit manager Carlo Beukes explains.

“Our new scraper chains, which are designed to withstand the toughest environments and handle the heaviest loads offer several key advantages over the previous generation. Important benefits include enhanced load capacity, improved impact and wear resistance and consistent performance in high-temperature applications, as well as minimal downtime and extended service life.”

He adds that the new links maintain their integrity over longer cycles, significantly reducing replacement frequency and minimising downtime. Further, the chain is manufactured to tight tolerances, ensuring compatibility and “trouble-free integration” with an existing system.

“The transition from the previous-generation material has been driven by our commitment to performance, advanced materials, the latest technologies and long-term value for our customers. This enhancement is not just an upgrade, it represents [improved] reliability for our customers.”

Key features of the advanced Fenner scraper chain include higher operational stresses without deformation, thereby delivering increased safety and high performance in demanding applications. The range has been designed to absorb shock and resist cracking under dynamic loads, ensuring greater resilience in heavy-duty operations.

The upgraded material offers “excellent strength retention” at elevated operating temperatures – a major advantage in continuous, high-friction environments. These scraper chain links, with optimised metallurgy and heat treatment processes, offer extended service life, contributing to a lower total cost of ownership.

This Fenner scraper chain has been developed to ensure efficient conveying in many industries, including trouble-free transport of slag granulates, ash or smelting residues from beneath boilers, burner furnaces and kilns.

Ash removal systems play a key role in the boiler and burner industry by safely removing waste materials. BMG specialists work closely with each customer to install the most suitable conveying method, in terms of reliability, simplicity and efficiency. Regardless of whether dry or wet ash removal is used, BMG’s focus is primarily on harmonising the processes, from collecting, extinguishing and cooling down ash, to safe storage in the ash bunker.

According to BMG specialists, conveying dry or wet ash is one of the most challenging applications to which a chain can be subjected. Conventional chains normally only function effectively for about a year, owing to abrasion and the varying ash temperatures, unlike BMG’s new range of high-performance ash conveyor chain.

Apart from upgraded materials, special attention has been given to dimensional accuracy, constant geometry, high surface quality and lubrication.

BMG also offers local companies the option to attach any configuration scraper flight. These flights, which are designed to comply with customer conveyor specifications, are welded and, importantly, are stress relieved to ensure they maintain their position during operation. A wide range of standard attachments is available, with technical details in the BMG Fenner catalogue.

The flexibility of BMG’s service includes the manufacture of a chain to suit exact requirements – with various options, including materials, custom coatings, lubrication and accessories – to create an “ideal” chain that boosts productivity and minimises abrasion. Through reliable maintenance support, BMG ensures high efficiency and extended service life of every conveyor system.