+27 11 899 0000

Lancaster Commercial Park, 12 Merlin Rose Drive (cnr. Lancaster Ivy), Parkhaven Ext.5, Boksburg, 1459

BI meets the demanding requirements of the food and beverage industry

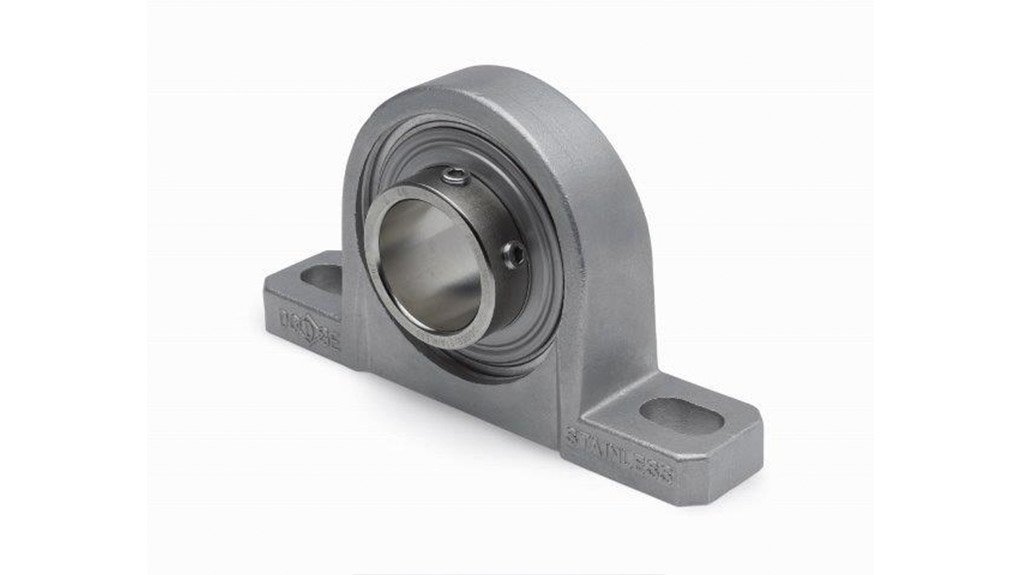

The food and beverage industry maintains a fine balance of priorities and requirements. Customers need dependable low and no-maintenance (sealed for life), cost-effective food-grade solutions that can withstand the rigours of corrosive, acidic, wet and excessively hot environments, with a focus on hygiene and food safety standards.

Leading supplier Bearings International (BI) has a range of bearing and power transmission solutions for all companies with food and beverage manufacturing, production, packaging, processing and distribution facilities, including OEMs, explains Market Segment Development Leader Hennie van Vuuren.

Where lubrication does take place, food-safe certified solutions is a necessity. However, added to this requirement and due to the nature of the application, solutions also have to have specialised sealing arrangements that are effective and can withstand being purged without damage.

“Meeting these demanding requirements is a high priority for BI,” comments van Vuuren. “We are well-positioned to service our customers with world-renowned brands known for these unsurpassed performance requirements in such a challenging environment.”

BI covers an extensive range of products and brands specifically for this sector. These include bearings and seals (FAG, Cooper, Koyo, Rexnord, Link-Belt, Craft and Dodge), power transmission products (Bauer, Dodge, Imak), linear motion products (INA), flat-top, stainless steel and plastic chains (Rex, MCC and Marbett), couplings and drives (Mayr, Jaure, Tschan, Motordrive), electric motors (Alpha Drive and ABB) and variable speed drives (V-Drive and Yaskawa).

“The food and beverage industry is the mainstay of society and our daily lives. Its importance is therefore immense, hence our ongoing focus to support this segment. Population growth alone is fuelling its rapid expansion. Hence there is a current market requirement for a robust, reliable and industry-specific supplier. With over 1 800 food production companies in South Africa, this is a major industry for BI,” comments van Vuuren.

BI’s strategy for the food and beverage industry is to be a supplier of choice, differentiated by quality service and products. “We strive to service our customers with product offerings from the most common to specially-engineered solutions, living up to our slogan of ‘always there making it work’. Due to our extensive footprint countrywide, we are able to engage with all roleplayers in this segment on a continual basis to ensure that our offering of quality, value-driven, cost-effective and sustainable products and solutions remains relevant,” highlights van Vuuren.

“We are always looking to improve, such as offering maintenance-free solutions and upgraded sealing arrangements. We are also looking to develop and supply sealed motorised drives for ease of use and durability as a bolt-on solution that requires no modifications,” reveals van Vuuren. He stresses the need for regular and proactive maintenance in the food and beverage industry.

“In this market segment in particular the ‘run to fail’ concept adopted by many other industries must be approached differently. Well-managed maintenance schedules with the assistance of BI will ensure more reliable, sustainable solutions, ensuring more uptime and a reliable supply to end-users,” concludes van Vuuren.