+27 11 899 0000

Lancaster Commercial Park, 12 Merlin Rose Drive (cnr. Lancaster Ivy), Parkhaven Ext.5, Boksburg, 1459

BI to expand offering in mining sector

BEST POSITION Bearings International is looking to bring stock holding to the mining sector to have stock in the branches, at the right place, at the right time

Bearings, power transmission and chain products distributor Bearings International (BI) hopes to increase its offering to the mining sector by providing various chain products to original-equipment manufacturers (OEMs) that supply equipment to this sector, says BI mining business development leader Shaun Combrinck.

“We are currently setting up an action plan to hit the ground running from April 2019. For 2019, we are looking at growing our market share in the sector by around 30% and to sustain this over the coming years,” he states.

Much of the equipment supplied by OEMs to the mining sector, such as tipper cars, continuous miners, roof bolters and drills, use and have BI chain products installed, he says.

“The OEMs are responsible for maintaining a machine provided to a mine for the first two years when it’s new. Once a chain on one of those machines breaks, they need to replace it. They bought the original chain from BI and, at that stage, they will order from us again. After that period has lapsed, the mine will be able to buy it from us if they wish,” he points out.

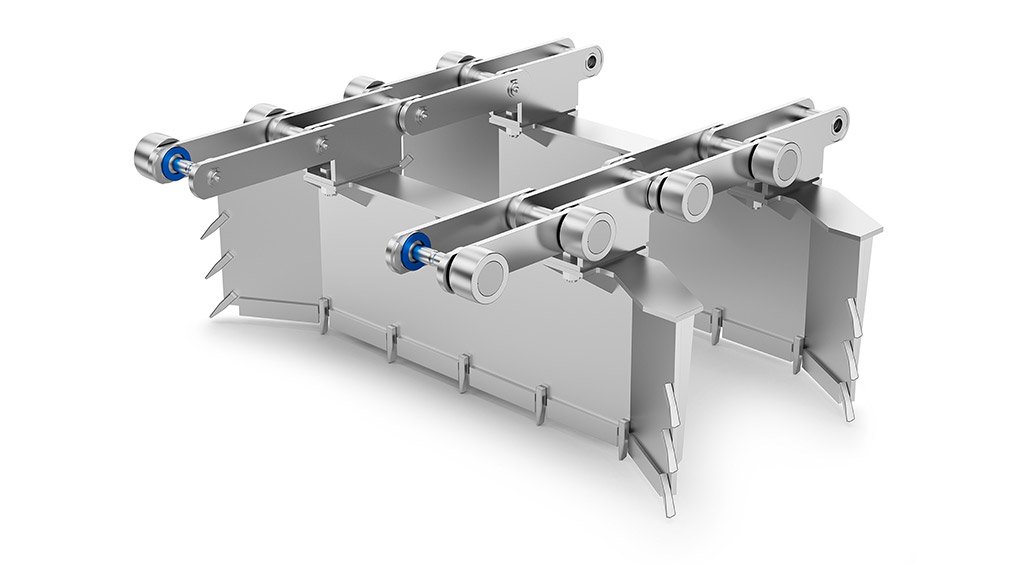

These chain products include products from German chains and sprockets producer KÖBO.

Since becoming the exclusive distributor of KÖBO in Southern Africa in 2017, BI has become a prominent supplier for these chain products to the Southern Africa cement, agriculture, and food and beverage sectors.

While the company also hopes to become a prominent supplier of these products in the mining sector, Combrinck emphasises the challenge in spreading brand awareness.

“You’ll have to have a three- to six-month test set up as a trial period in which the products are used on a mine, and only thereafter will it be approved on the mine. Now you need to start selling it to the mine. It’s approved, but that’s not to say that you can supply to the miners all of a sudden.”

Combrinck states that BI started off by supplying chain products, such as KÖBO products, to companies involved in quarrying projects. These products include hot pan conveyor chains, bucket elevator chains and feeder breaker chains. BI has also secured contracts to supply such chain products to cement producers in the Western Cape and North West.

BI hopes that these contracts, as well as the sector-specific managers that BI has employed to focus on providing products for different sectors of the economy, will assist the company in building a good relationship with mining sector clients.

BI branch managers are visiting the clients, while the company is also providing training on maintaining and changing the chains, and what to look for in terms of mine-specific products. This will include the drills, stacker reclaimers, and all the chains used in opencast and underground mining, Combrinck explains.

Mining Chains

While chains in the cement and mining sectors have similar applications, Combrinck highlights how chains used in mining, such as drum chains and scraper chains, are generally larger and made from different materials.

These materials include mild steel, which vary in hardness depending on the application and can range from three-quarters of an inch to six inches style. The application can affect the material used. For example, in salt and heavy minerals plants, the salt and minerals corrode the chains.

Certain chains used in mining are also required to have sprockets that have hardened teeth to ensure the longevity of the chain, owing to the harsh conditions, particularly when compared with chain products used in the agriculture, and food and beverage, sectors, explains Combrinck.

The food and beverage sector uses smaller and more intricate chains than those used in the mining sector, and those chains are changed quite often every year, he says.

He also emphasises that chains used without lubrication are more appropriate for the mining sector, and will result in the longevity of the chain product used, as opposed to chains that do use lubrication. He explains that because of the lubrication of a chain used in mining applications, dust becomes attached to the chain and creates a grinding paste, which wears out and reduces the quality of a chain.

Combrinck states that the most significant opportunity for BI to expand into the mining sector lies in its chain offering, and particularly in providing convenient stock holding options for mining companies.

Last year BI expanded its agricultural products portfolio by signing a deal with agricultural group OVK to place consignment stock at OVK branches in 2019. Combrinck states that BI hopes to pursue similar endeavours in the mining sector.

“Our product range, as well as the stockholding in the agricultural sector, is quite good. We’re also bringing that offering to the mining side – get the right stock in, have it at the branches at the right time, at the right place.”

He explains that BI focuses extensively on customer service and regular follow-ups in terms of service provision, such as setting up new contracts and new consignment warehouses for outlaying clients that could be in more isolated and remote areas.

“The companies are biting for this, they want that type of service,” concludes Combrinck.