+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

Components provider extends offering for sugar industry

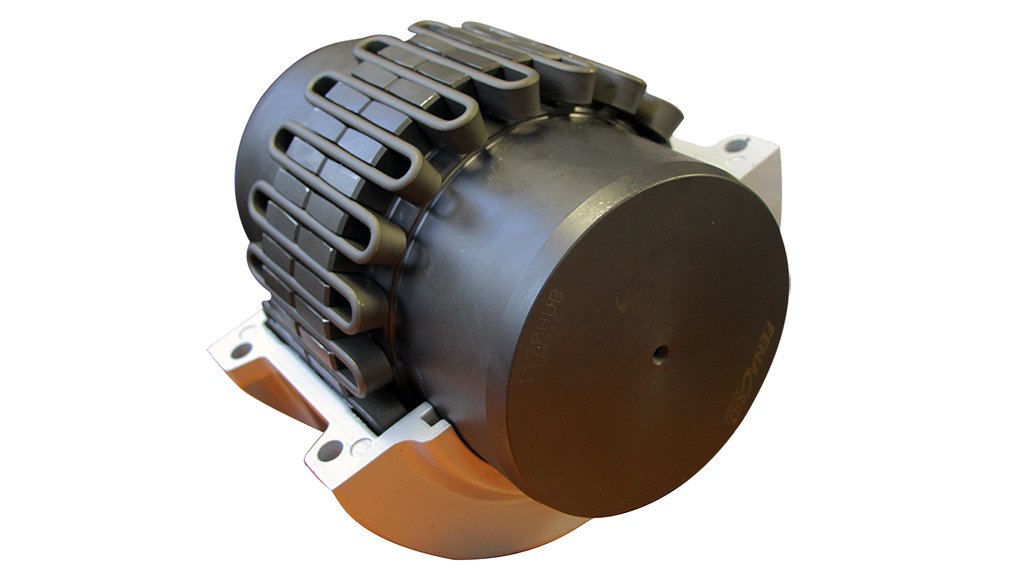

SOAKING UP BMG’s new Fenagrid Premium taper grid steel flexible couplings absorb considerable torque overloads, achieving smoother running, with consequent reduction of wear and tear on machinery

Engineering components provider BMG has extended its range of power transmission components to include its recently upgraded Fenagrid Premium range.

The new Fenagrid Premium taper grid steel flexible couplings are well suited to the harsh conditions in sugar processing and production, the company says.

The couplings accommodate angular, parallel and axial misalignment between driving and driven equipment.

These grid couplings absorb considerable torque overloads, achieving smoother running, with the consequent reduction of wear and tear on neighbouring components.

BMG power transmission business unit manager Carlo Beukes says the new couplings are a result of the upgrade of multiple aspects of the previous generations and include dimensional, material and manufacturing improvements.

These hubs are manufactured from a high-strength hardened alloy steel to withstand extremely high torque loads, he explains.

“Another important feature of the new range is that all couplings are dimensionally compatible with that of other leading power transmission brands. This means that couplings can be interchanged quickly, with a minimum loss of production time,” he comments.

Beukes advances that Fenagrid Premium taper grid steel flexible couplings have a trapezoidal cross-section and are tempered to spring hardness, with the surface molecules compressed by high-velocity steel micro-beads through a shot-peening operation.

The compression of molecules results in increased strength and flexibility, which means higher torque ratings and a longer L10 life. The grids are easily identifiable, owing to the word ‘premium’ having been etched onto them.

Additionally, the couplings have been designed to float, rock and pivot within the hub teeth. This, BMG says, provides generous capacity for misalignment without producing detrimental axial loads on bearings that occur when couplings are misaligned.

The grids are also able to deflect torsionally when subjected to normal shock or vibratory loads. The taper grid system is a shock absorber for rotary motion, relying on the predictable resilience of the grid for torsional flexibility.

Owing to their spring hardness and flexibility, the grids absorb impact by spreading the energy over time. They also dampen vibration and reduce peak or shock loads experienced by the entire mechanical system, Beukes highlights.

Moreover, BMG supplies a range of products, selected especially for demanding conditions in the sugar industry throughout Africa.

These components include carrier and diffuser chains, knife and shredder bearing housings, custom sprockets and gear couplings, as well as steam gaskets, heat exchangers and hydraulic tools.

“Diffuser and mill gearboxes, in addition to mill lubrication and hydraulic systems, form a critical part of this range,” Beukes points out.

The company’s specialist services to the sugar sector include bearing and gearbox inspection, bearing and chain refurbishment, large-size bearing assembly, alignment and balancing, as well as customised product design.

Subsequently, BMG also offers a troubleshooting and maintenance service, condition monitoring and training.

Further, the BMG team works closely with chief engineers during every process in the sugar industry, providing engineering solutions and technical services to enhance production efficiencies, he enthuses.

For instance, BMG’s newly launched heavy duty coupling grease has been specifically formulated for gear and grid couplings, which are subjected to the combined action of high load, shock load, water and elevated temperatures at sugar refineries and mills.

This heavy-duty coupling grease operates efficiently in harsh environments and has “excellent extreme pressure properties” that provide a stable and adherent film, with resistance to mechanical action and water.

The grease also has high-quality anti-corrosive properties for ferrous materials, as well as copper alloys, bronze and brass. He comments that components in the grease, including sulfonate complex calcium soap and solid lubricants, allow for safe operation in a temperature range, especially at high temperatures.

“In addition, excellent physical and chemical properties reduce lubrication intervals, prevent wear and tear, and extend the service life of equipment.

“This specialised grease is available from BMG in 500 g and 5 kg containers,” concludes Beukes.