+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

Durable drives for belt conveyor systems

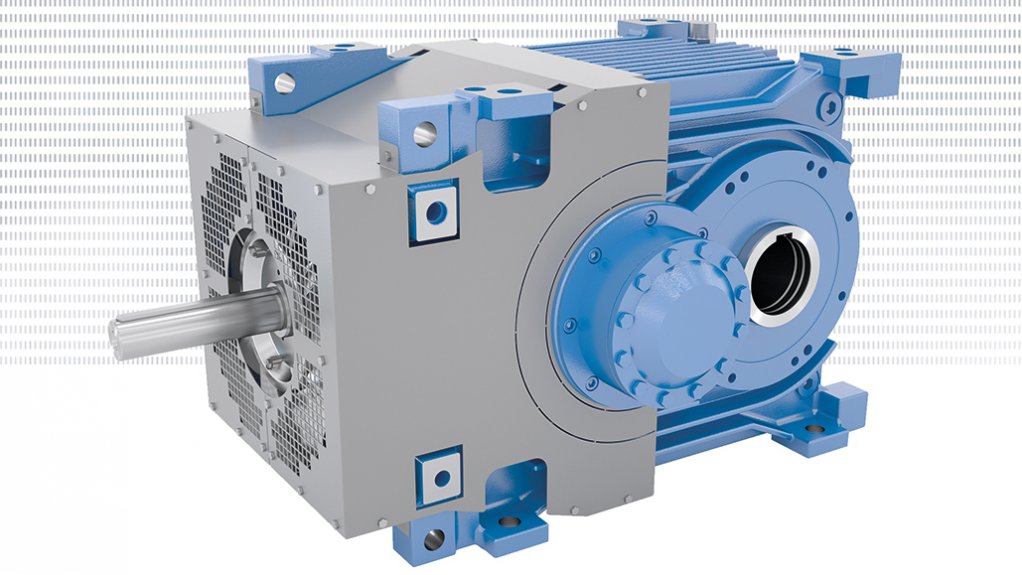

MAXXDRIVE XT The industrial gear units are tailored to applications where high powers with low speed ratios are required

Industrial equipment supplier BMG reports that its NORD Maxxdrive-XT industrial gearboxes, launched at the Electra Mining trade show in 2022, have been well received by users in bulk logistics, particularly for use in belt conveyor systems.

Maxxdrive-XT industrial gear units – developed by technology solutions

provider NORD Drivesystems to meet the demands of conveyor technology drives used in the handling of bulk goods and minerals – have advanced features for high thermal and mechanical load capacities, durability for extended service life and low maintenance requirements.

“The power and speed ranges of the two-stage, right-angle gear units have been specially designed for industries that require low speed ranges, in combination with high powers,” explains BMG Electromechanical Drives division gears national sales manager Deon Crous.

“Our drive solutions are individually configured for customers according to the modular principle which is based on a wide range of frequency inverters, motors and gear units, as well as coupling and brake systems, each with various options.

“Features include hydraulic couplings that are tailored for a particular process, and Taconite seals, which protect radial shaft seals against abrasive dust and corrosion to ensure smooth operation and low maintenance requirements, even in tough operating conditions.

“Large roller bearings and centre distances increase the load capacity of the system and extend service life of components,” he says.

The standard industrial gear unit is equipped with a heavily ribbed UNICASE housing and an integrated axial fan. Owing to the increased surface and airflow covers, the cooling airflow is improved and a high thermal limiting power is achieved. In many cases, additional cooling is not required.

Maxxdrive-XT units, which provide output torques of between 15 kNm and 75 kNm, with speed ratios from 6.3 to 22.4, are available from BMG in seven sizes and range in power from 22 kW to 2 100 kW.

In addition, customised explosion-protected motors and geared motors are used to reduce the risk of an explosion of flammable dust in bucket conveyor applications.

BMG also supplies and supports NORD Maxxdrive-XD industrial gear units, which have been designed to enhance the efficiency of lifting gear used in many industries.

NORD Maxxdrive-XD industrial gears offer solutions in lifting applications that place higher demands on limited installation space for drives. This system has an increased centre distance that is ideally suited to the U-shaped configuration of the drive, motor and cable drum used in lifting equipment of cranes.

The housing of the Maxxdrive-XD gear units has been specially designed for lifting applications and enhanced for downward loads. The elongated arrangement of gear stages also enables a mechanical, tailor-made dimensioning of the gear unit with sufficient centre distance – thereby avoiding an over-dimensioning.

Maxxdrive-XD industrial gear units are suitable for use in mining and quarrying, ports, logistics and shipyards, in metals, chemicals and paper facilities and for bulk goods transshipment.

With the launch of these new industrial gearboxes, BMG is able to offer a complete package of running gear and lifting gear drives for cranes from a single source.

BMG’s team of technicians supports the NORD range with a technical advisory and support service, which is tailored to meet the precise specifications of contractors, designers and the end-user. Local assembly at BMG World in Johannesburg, enables prompt delivery of drive systems and the quick availability of spare parts.