Godwin pumps keep Zambian gemstone mine dewatered during rainy season

Godwin HL160 Dri-Prime pumps from Integrated Pump Technology are keeping dewatering operations running smoothly at a Zambian gemstone mine, even during the rainy season

Integrated Pump Technology supported the mine team with on-site commissioning and technical setup to ensure a successful start-up

Selected with future pit deepening in mind, the Godwin HL160 pumps are capable of handling increasing discharge heads over the next few years

Assembled locally in South Africa, the Godwin HL160 pumps were delivered and operational within six weeks - much faster than importing from Europe

Each pump is powered by a 403 kW Perkins C15 diesel engine, making it ideal for remote and demanding mine sites

Operator training was included as part of the handover process, empowering the customer’s team to manage and maintain the equipment confidently

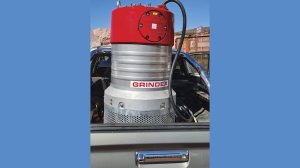

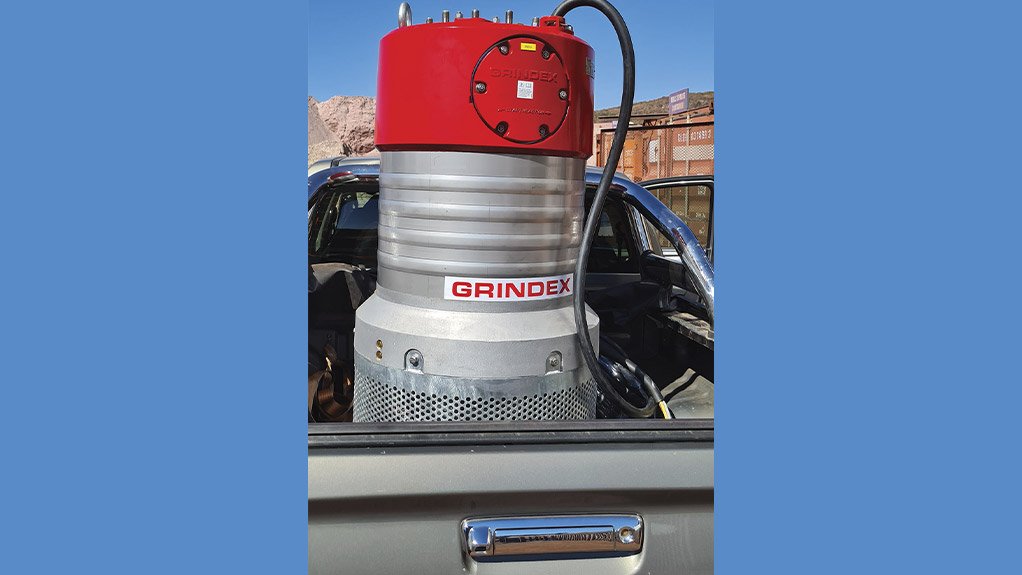

At a gemstone mine in Zambia, dewatering is critical to keeping the open pit both safe and productive. Two Godwin Dri-Prime HL160 pumps from Integrated Pump Technology have enabled mining operations to continue uninterrupted - even during the demanding rainy season.

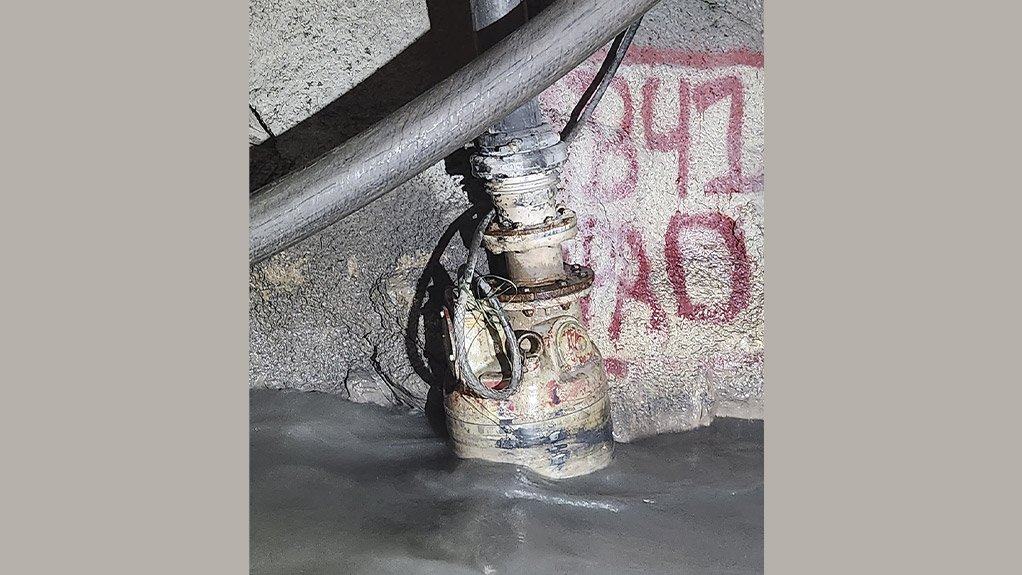

JD Nel, Godwin Product Manager at Integrated Pump Technology, explains that the site’s existing pumps were no longer able to manage the volumes required to keep working areas dry. In collaboration with local distributor IES, the company specified the appropriate pump solution to meet the mine’s duty requirements.

“Together with IES, we conducted a site visit to assess the conditions and engage directly with the customer,” says Nel. “Wherever possible, we also train customer staff to gather the right data for accurate pump selection - something the team on site greatly valued.”

In this application, the pumps needed to move approximately 300 m³ of water per hour to a discharge head of 130 to 140 metres. Integrated Pump Technology and IES also reviewed the pipeline and accessory requirements to ensure these were correctly specified for optimal performance.

“While assessing the current conditions, we also considered the future deepening of the pit,” says Nel. “This is why we recommended the Godwin HL160 units; they are more than capable of handling increasing discharge heads over the next two to three years.”

Compact yet powerful, the Godwin HL160 pumps used at the site are driven by 403 kW Perkins C15 diesel engines and deliver flows of more than 480 m³ per hour with discharge heads approaching 190 metres. Nel highlights that local assembly in South Africa significantly reduces delivery times.

“Bringing these units in from Europe could take 22 to 24 weeks,” he notes. “With Integrated Pump Technology’s local production capabilities, we were able to shorten that lead time by 10 to 15 weeks and get the dewatering pumps and associated equipment operational within four to six weeks.”

This was a key consideration for the Zambian mine, as the rainy season posed a serious risk to production.

“Our technical specialists were also on site to assist with setup and commissioning and to provide additional training so the customer’s team could operate the units with confidence,” Nel concludes.