Local heat exchanger industry waning

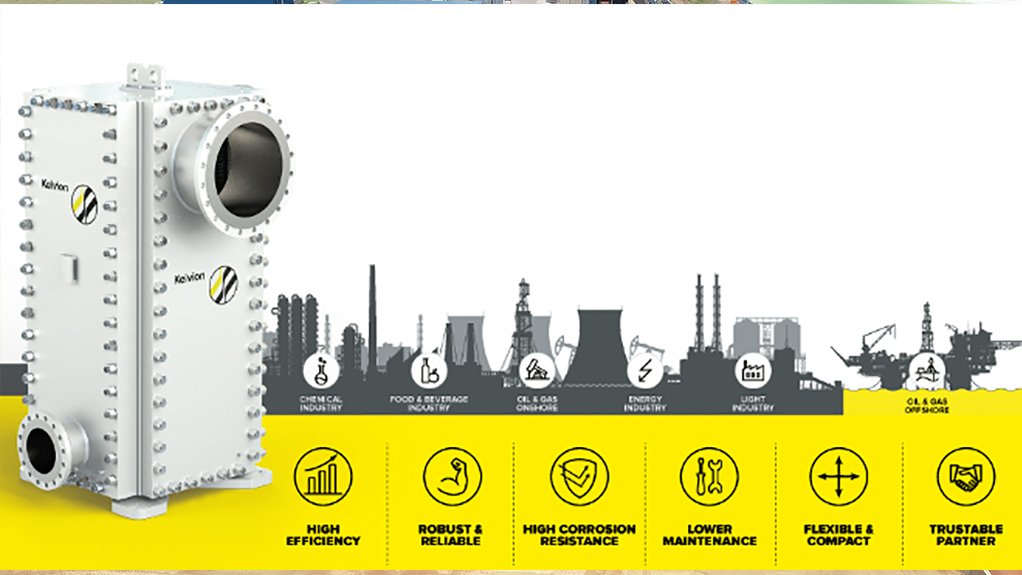

RENEWABLE FOCUS Kelvion's K° Bloc heat exchanger handles high pressures and high temperatures, and can be used in various energy industries such as hydrogen and renewable energy

The local heat exchanger industry is facing challenging times owing to factors such as the Covid-19 pandemic and the country’s economic state, says heat exchange solutions provider Kelvion operational manager Pieter Herbst and MD Alex Dreyer.

“Not only is the heat exchanger industry facing a decline but the manufacturing sector in general is also in a bit of a slump,” says Herbst.

He adds that these issues can be attributed to an array of factors, such as people no longer investing in the maintenance of heat exchangers, which, in turn, has affected the company over the past two years, with many key players in the industry having closed their doors.

Companies closing down has affected business for Kelvion, as long-established relationships with these businesses no longer exist.

Dreyer adds that Kelvion’s primary business is in the petrochemicals industry, which has also been declining, owing to many key players, such as petroleum companies Engen, PetroSA and Astron currently not being in operation,

Hence, companies in the heat exchanger industry now aim to “stay marketable and weather the storm”.

Despite challenges, Kelvion stays afloat because of its diverse product range, manufactured locally and overseas.

“One cannot simply be the niche manufacturer anymore, you must be open to adapt according to what the market requires to meet demand,” says Herbst.

However, he says there has been an upswing in the local heat exchanger industry and globally, as economies are starting to recover from the effects of the pandemic.

“The future looks promising. Despite pushbacks over the past two years, things can only get better for Kelvion and the local industry,” says Dreyer.

They add that localisation is important, with companies in the industry encouraged to support local manufacturers rather than import and invest overseas.

New Industry Focus

Dreyer says conventional shell and tube heat exchangers could leak, which, in turn, can cause two potentially hazardous fluids to mix or pollute water sources.

Hence, Kelvion, internationally, is focussing on green industries, such as green hydrogen and nonhydrocarbon, to which the company supplies heat exchangers.

Double-tube exchangers allow for leaks to be detected externally, which mitigates potential hazards, as two tubes are placed within each other. Thus, if there is a leak, the fluid would leak into the gap between the two tubes before it gets into, and pollutes, a water source.

However, Dreyer says many clients in the petrochemicals industry continue to use conventional heat exchangers, owing to double-tube heat exchangers being “offbeat”, but he expects it to become more popular over time.

Further, Kelvion’s K° Bloc heat exchanger, released in 2020, plays a key role in its package of sustainable solutions.

The heat exchanger handles high pressures and high temperatures, and can be used in various energy industries such as hydrogen and renewable energy.

The K° Bloc is a welded plate pack inside a pressure-retaining envelope, making it a more compact and cost-effective heat exchanger, particularly in the petrochemicals industry.

While the product is not widely used in South Africa, Dreyer says there are plans for the K° Bloc to be used in the hydrogen sphere by companies such as chemicals company Sasol.

The heat exchanger, with increased reliability and efficiency because of its enhanced welding structure, is more widely used in Europe, particularly in the gas industry.

Additionally, the dual internal and external structured tube for air fin coolers can be used in the oil and gas industry, and reduces plant costs by more than 10% in certain applications.

“It is basically the same heat exchanger that we would build for a refinery, but the fins on the tubes look different, and it gives you a 10% or 15% advantage overall on the size of the heat exchanger, which drastically reduces the footprint by consuming less energy,” Herbst and Dreyer explain.

Currently, Kelvion focuses on maintaining local power plants.

“We are maintaining older power plants in South Africa, from State-owned power utility Eskom's power stations to power plants in Secunda,” concludes Dreyer.