+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

More demand for lower costs and efficient designs

SO, SO VERSATILE BMG’s cam clutches can also be used for belt conveyors, metals, timber, pulp and wood chip, as well as bucket elevators for cement and grain

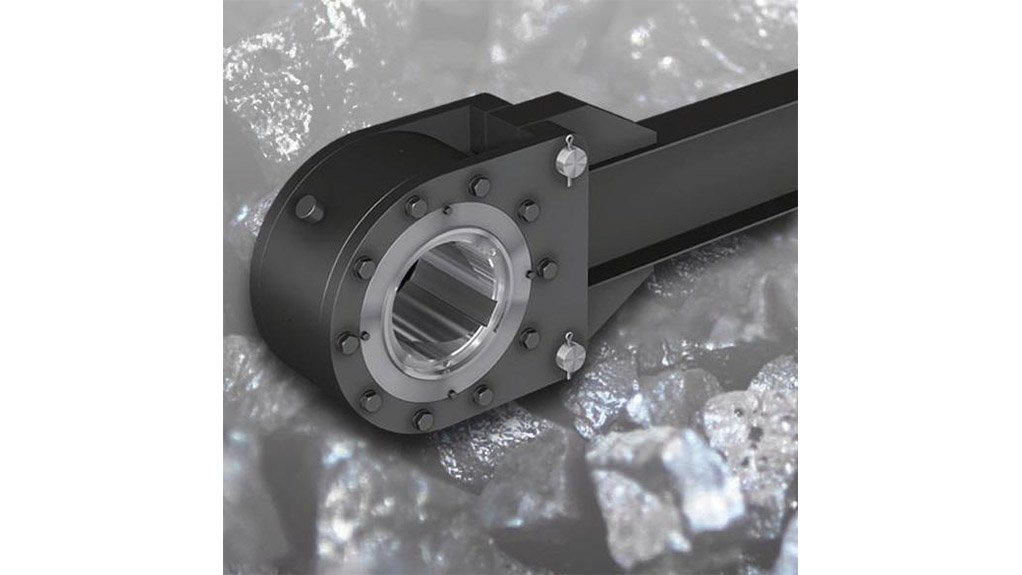

IN WITH THE NEW The Tsubaki backstop can accommodate much higher speeds and more torque than the older technology

There has been growing demand in the conveyor market for more compact and efficient designs at lower costs, says industrial equipment supplier BMG.

MG Tsubaki product specialist Gavin Kirstein says it is possible to downsize units and keep the required torque capacities, thus enabling clients to reduce running costs.

BMG’s BS-F series, which forms part of its Tsubaki backstop cam clutches range, is designed for high-speed inclined and long overland belt conveyors, as well as bucket elevators. The series is used mainly in the mining and bulk handling sectors.

Tsubaki’s backstop cam clutches are designed to prevent reverse rotation of drive shafts, offering a simple and cost-effective means of protecting capital equipment and enhancing safety, adds Kirstein.

“The high-torque, high-speed Tsubaki BS-F series, with a narrow width I-beam torque arm, is a drop-in replacement to conventional anti rollback devices. “This allows for quick and easy on-site installation and replacing an old backstop with the new BS-F design without the need for modification to the existing layout.”

Although this series has a narrower width than other models, the downsized unit exceeds the requirements of high-speed inclined belt conveyors, with the benefits of space-saving and reduced installation time, he explains.

A common cause of conventional backstop failure is oil leakage. Kirstein states that the company has eliminated this risk in the new BS-F series by designing the backstop to operate with grease and a specially designed labyrinth seal.

“The absence of an oil-level gauge creates a more reliable safety device,” he enthuses.

Some of the other important features in this series include a nonrollover cam and roller design, which offers higher backstop torque capacities and lower running temperatures than conventional anti rollback devices.

Further, a flexible labyrinth seal mechanism prevents the ingress of dust and water in abrasive conditions, while a double-lip oil seal and multi-temperature grease allow for safe operation at an ambient temperature range from about 40 ºC to 65 ºC.

“The Tsubaki backstop can accommodate much higher speeds and more torque than the older technology. As the market grows more confident with the newer technology, the implementation of the technology is also increasing,” he tells Engineering News.

The cam and roller cage orbit at low speed continually conveys grease internally, from the bottom to the top of the mechanism. The constant circulation of grease minimises internal friction and reduces operating temperature for dependable operation.

As such, the maintenance intervals are between 7 500 h and 8 000 h. This means the effective service life of the units is also significantly extended when compared with conventional oil-filled units, the company says.

“BMG’s technical team conducts full plant surveys and advises on the selection of the correct cam clutch for each application, and the appropriate installation and use for optimum performance and improved safety standards. “For extended service life, the correct lubrication methods and dust prevention care are critical.”

The company recommends using a maintenance kit and Tsubaki-approved EP-free grease for easy and effective maintenance of the BS-F series. BMG offers clients a complementary Tsubaki maintenance kit with the BS-F series, which is larger than a 200 mm shaft and allows for easy servicing of the unit during operation, without having to remove it from the shaft.

“South Africa’s Mine Health and Safety Act states that the installation of incline conveyor belts must include the fitting and use of one or more devices to prevent run-back or run-on, to avoid injury by materials or minerals falling from a conveyor belt. Tsubaki backstop cam clutches – designed for safety in high- or low-speed applications – meet the requirements of this legislation,” Kirstein maintains.

BMG’s cam clutches can also be used for belt conveyors, metals, timber, pulp and wood chip, as well as bucket elevators for cement and grain.

“These units are also installed to enhance the performance of large drift conveyors and screw pumps.”

BMG stocks a variety of the Tsubaki backstops locally and subjects every unit to a test run before delivery.

The complete range of Tsubaki power transmission components is also available from BMG’s national branch network, which offers a technical advisory and 24-hour backup service.

“Tsubaki has continual research and development programmes on all its product ranges, with facilities worldwide to ensure that they have solutions to every emerging need in the market,” he concludes.