Quality aggregates are the foundation of strong, durable construction

Amit Dawneerangen, Construction Materials Executive: Sales & Product Technical at Afrisam

To ensure full compliance with relevant standards and specifications, AfriSam conducts a range of aggregate tests both in-house and through external laboratories

AfriSam carries out multiple process control tests as an integral part of its daily production operations to maintain consistent product quality

The COTO specifications for aggregates used in asphalt - classified as Class 1 and Class 2 - set exceptionally high quality standards

Both coarse and fine aggregates used in concrete must comply with the requirements of SANS 1083

AfriSam laboratory personnel regularly collect samples from each stockpile, with testing conducted on an ongoing basis to ensure product integrity

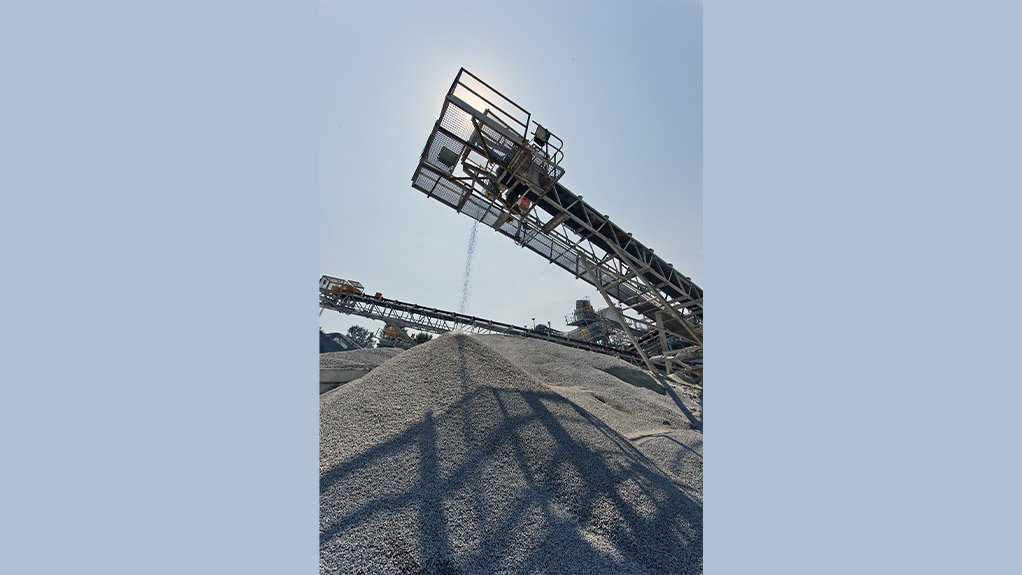

In the world of construction, the quality of materials directly determines the strength, durability and long term performance of any structure. Among these materials, aggregates - whether used in concrete, asphalt or base layers - play an essential role. Ensuring that aggregates are correctly sized and properly graded is not just a technicality - it is a vital factor in achieving structural integrity, performance consistency and compliance with design specifications.

“Aggregate grading is about more than just particle size,” Amit Dawneerangen, Construction Materials Executive: Sales & Product Technical at leading construction materials supplier, AfriSam explains. “It determines how the material compacts, how concrete mixes perform and how well load bearing structures can handle stress over time.”

When aggregates are incorrectly sized or poorly graded voids can occur within the mix, reducing density and compromising strength. This often leads to issues such as cracking, shrinkage and water ingress - all of which can shorten the lifespan of roads, buildings or infrastructure.

Conversely, well-graded aggregates create dense cohesive mixtures that enhance workability, reduce cement or binder demand, and ensure more uniform compaction and stability.

Beyond physical performance, consistent aggregate quality ensures that engineers and contractors can meet design standards and regulatory specifications. Projects designed around specific grading envelopes depend on accurate and repeatable aggregate properties to perform as intended.

However, achieving this level of precision requires technical expertise, process control and rigorous testing which is why working with a reputable quarry or construction materials supplier is critical. Trusted suppliers operate under strict quality management systems, implement regular laboratory testing and maintain calibrated crushing, screening and blending processes to ensure product consistency.

“Partnering with an established, credible supplier provides confidence that every load delivered meets specification,” Dawneerangen adds. “It also means access to reliable technical advice and traceability - from the source rock right through to the final product.”

Reputable suppliers invest heavily in quality assurance infrastructure, from advanced testing laboratories to on-site quality control technicians. Their focus extends beyond supply - they actively collaborate with engineers and contractors to ensure that the correct material is selected for each layer or mix design, reducing the risk of costly rework and ensuring long term performance.

In a market where quality, compliance and sustainability are non-negotiable, correct aggregate sizing and grading are the cornerstones of successful construction. “Working with a trusted technically capable supplier is therefore not just a purchasing decision - it is a quality assurance choice that safeguards the integrity and longevity of every project,” Dawneerangen concludes.