SKF launches resilient mount Vibracon kit at SMM 2016

SKF is using the SMM 2016 trade fair (Hamburg, 6-9 September) to introduce a new one-box kit version of its proven Vibracon technology for the quick, accurate and clean alignment and chocking of resilient mounts.

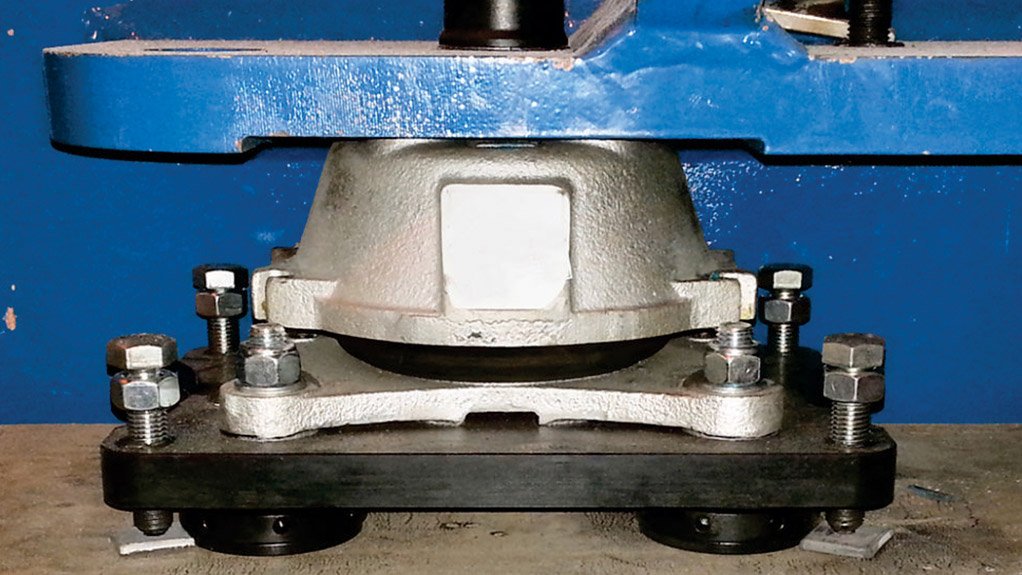

SKF has introduced a new Vibracon kit for the clean and permanent alignment and chocking of resilient mounted equipment. Presented to the global market for the first time at SMM 2016, the universal chocking solution is particularly quick and easy to use on resilient mounts in the maritime industry, such as those under engines, generators and skids, and is both adjustable and reusable.

Each complete kit comprises all the components needed for one resilient mount, including SKF Vibracon chocks, an adaptor plate, SKF spherical washers, an adjustment tool, foundation bolts, nuts, jack bolts and locking bolts. It is delivered as a one-box solution for trouble-free implementation, and allows for alterations and height adjustments during the installation process to achieve accurate alignment and even load distribution for optimum application support.

The new Vibracon kit also ensures compliance with resilient mount manufacturers’ installation requirements, and offers slope and angular compensation without the need for time-consuming traditional chocking methods, such as the welding of machined steel plates and the use of epoxy resins. Furthermore, as it eliminates the problems and waste associated with high temperatures, welding fumes and resins it is far cleaner than conventional chocking processes and can reduce the environmental impact of the application.

SKF experts were available on the stand at the leading international maritime trade fair to give more information and visitors were able to see a demonstration of Vibracon kits for resilient mounts.

The solution is available for immediate delivery.