+27 11 899 0000

Lancaster Commercial Park, 12 Merlin Rose Drive (cnr. Lancaster Ivy), Parkhaven Ext.5, Boksburg, 1459

Supplier diversifies product offerings to grow in Africa

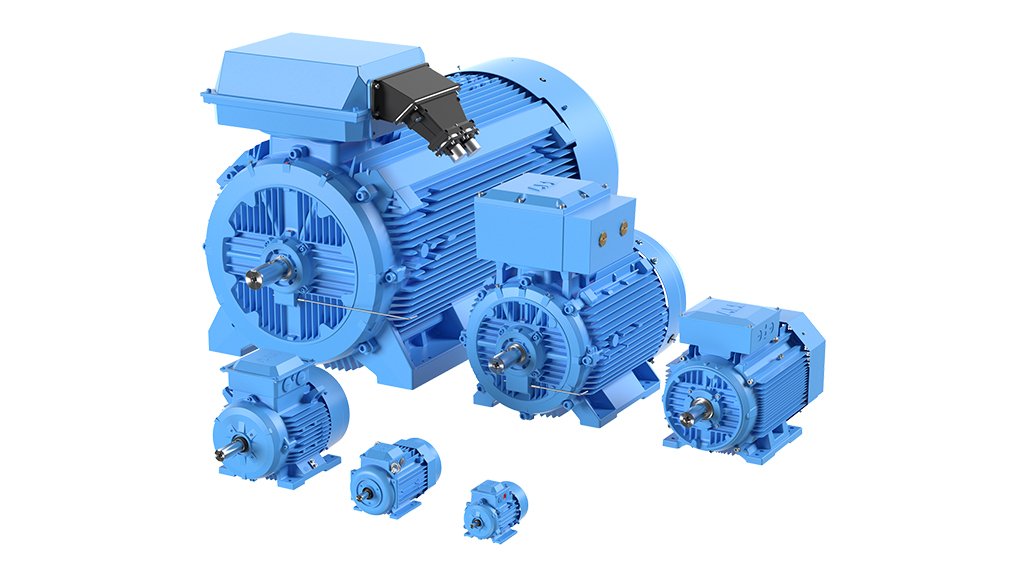

LOW VOLT HIGH DEMAND The demand for ABB's low voltage motors has been Bearings International's sales figures glow despite Covid-19

Bearings and power transmission distributor Bearings International (BI) South Africa, a member of the Hudaco group, has expanded its offerings to include low voltage motors of electric motor manufacturer ABB for supply to BI’s sub-Saharan Africa clients.

“The decision to become an ABB distributor and Channel Partner was made as part of BI’s drive to become one of the most prominent industrial consumable suppliers globally,” says BI motors and drive business unit leader Stephen Bekker.

Over the past two years, following the establishment of BI’s new motors and drives division in early 2020 – a trying time for many companies, owing to the global pandemic which halted most projects – the company has developed the division, beginning operation earlier this year, and supplying motors to clients from the second quarter.

BI currently holds the full range of ABB’s low-voltage process performance motors in stock at its Parkhaven branch, in Boksburg, as well as over 42 branches across South Africa, and can import any larger motors if needed.

“The low-voltage process performance motors offer power output ranging between 0.12 kW and 1 000 kW,” he adds.

The range, made from cast iron or aluminium, is used in a variety of applications.

The motors are ideally suited to process industries and heavy-duty applications, where motors have to meet high requirements for reliability, availability and efficiency in harsh conditions.

“The range is robust and manufactured to handle the dry, dusty and hot environments in the Southern Africa mining and industrial sectors,” Bekker enthuses.

BI also has access to the ABB Synchronous reluctance motors range, which according to International Electrotechnical Commission (IEC) standards offers one of the best efficiency ratings globally.

Bekker avers that, when deciding what motor to buy for a project, the client must prioritise the running costs of the motor, rather than the initial capital outlay.

The breakdown of the cost of a motor over its life span amounts to 96% electricity use, 3% purchasing cost and a “miniscule” 1% for maintenance.

Consequently, the more energy efficient the motor, the less energy it uses when in operation, consequently saving on costs and decreasing the client's carbon footprint.

The ABB Synchronous Reluctance range has become commercially viable as a high-efficiency alternative to the induction motor in recent years, says Bekker.

He adds that the ABB process performance motor range boasts IE2, IE3 and IE4, depending on the motor selected, while the Synchronous reluctance range offers energy efficiency ratings of up to IE5.

The IE ratings are defined by the IEC, which publishes international standards for all electrical, electronic and related technologies – collectively known as electrotechnology.

Additionally, all the ABB motors which BI supplies are IEC 60034-certified, CE-certified and conform to SANS 1804.

Bekker adds that BI’s sales and technical teams have been selected and trained to assist in selecting the best product for clients’ specific requirements.

He tells Mining Weekly that BI has shown an increase in sales of about 26% a year, despite Covid-19 and its impact on sales and imports.

“We anticipate, with our current trajectory, that we will be able to maintain the growth rate at the close of this year as well,” Bekker concludes.