+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

Supplier hones in-country offering

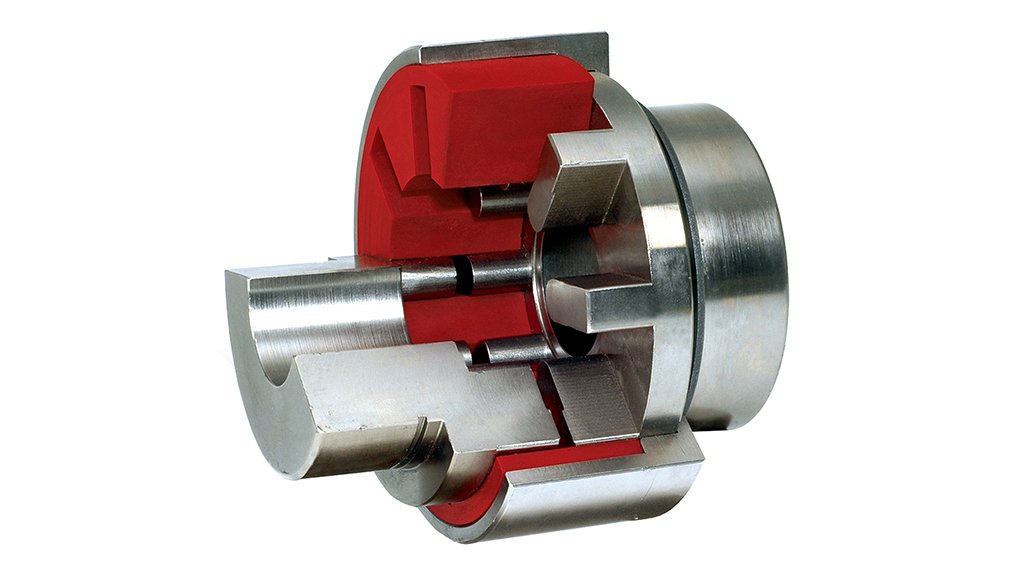

QUICK FIX BMG's Timken Quick Flex is just one of many solutions offered by the company in Zambia

Industrial products supplier BMG has established itself in Zambia as a single point of contact and reliable supplier of all essential quality branded products and essential support services, thereby ensuring high productivity, reduced energy consumption, reduced downtime and long service life of associated systems, notes BMG Zambia country manager Ian Smith.

BMG’s operations in Zambia include facilities in Lusaka and Kitwe that provide power transmission components and support services to all sectors.

BMG also supplies and supports service providers to power generation and pharmaceuticals plants, as well as ports, rail and road facilities.

“BMG is a complete process solutions provider to all sectors of industry,” he says.

He adds that BMG’s integrated approach guarantees lower production costs and higher efficiencies.

“We believe the introduction of a structured maintenance management programme, which can be implemented in-house, or partially outsourced to a professional organisation, is critical to maximising production efficiencies in all industries,” says Smith.

BMG’s power transmission division is committed to keeping every plant in a state of being fully productive for as long as possible, without unnecessary maintenance or unplanned stoppages.

As a result, output capacities are increased without the investment in additional production lines and machinery.

Downtime, as a result of breakdowns or routine maintenance, is a critical factor affecting efficiency and production, especially in the mining industry.

“The stock availability of a wide range of standardised components, which are machined to accept taper-lock sleeves with bore sizes to suit a range of standard size shafts, facilitate easy fitting of these components to the shafts of machinery, such as motors and gearboxes,” he notes.

Further, installation time is reduced by eliminating the necessity for on-site machining.

Standardised components, like V-belts, sprockets, couplings, slat top chain and belt systems, taper bushes, belt and chain tensioners and geared motors accommodate broad power input and torque capacity requirements, as well as a wide speed range.

Smith points out the accurate installation of correct power transmission equipment ensures a long-term saving in equipment replacement costs, as well as reduced plant downtime and maintenance requirements.

When alignment has been meticulously completed, it is critical that all components are securely located and doweled, ensuring reduced wear, resulting in lower power losses, improved efficiency and eliminated vibration.

“The net effect is an extended operating life for all drive components,” he states.

In belt and chain drives, the correct tensioning and accurate alignment of pulleys or sprockets also extends operating life of components and as a result of reduced friction, power consumption is lowered, concludes Smith.