Support for mill circuit pumps

Weir Minerals Africa says that technical support and selecting the correct mill circuit pump are critical to ensuring optimal performance of a mill circuit. The company asserts that its solutions ensure optimum performance and low total cost of ownership.

Weir Minerals Africa pump products GM Marnus Koorts says that the requisite support level often requires significant investment by the pump original equipment manufacturer and means having the correct parts readily available on or close to a customer site. This should be backed by the technical competency required to keep the pump running, he says.

“What is essential to understand is that a mill circuit pump is not an off-the-shelf solution. Mill circuit pumps are engineered to provide optimum performance under the arduous operating conditions on individual customer sites and need to be configured to achieve the requisite hours between scheduled maintenance shutdowns,” he says.

He explains that one of the primary considerations when it comes to mill circuit pumps is the ability to handle large particles and high flow rates. Wear and tear in these pumps are directly proportional to the size of particles passing through, necessitating specific construction materials and design features.

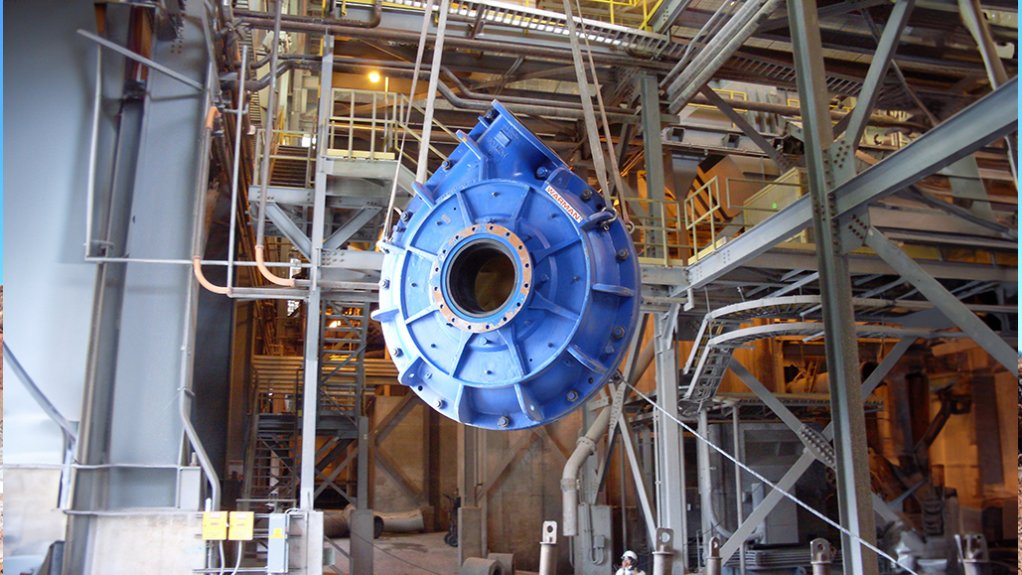

The company asserts that the Warman mill circuit pump is the preferred choice for mill circuit plants across Africa. Koorts notes that the Warman mill circuit pumps are physically larger for the same flow rate, reducing wear by operating at lower speeds.

“Another crucial aspect is the engineering of the hydraulic chamber, which enhances wear resistance and increases efficiency. This is achieved through the unique design of the vanelet which significantly minimises unwanted turbulence and reduces both wear and energy consumption,” he explains.

Weir Minerals notes that it has invested in rubber production facilities to manufacture rubber liners, as these liners offer benefits such as extended wear life and the ability to withstand the impact of large particles. Rubber liners are also said to be more cost effective and easier to handle.

A range of metal options are also available, if required for specific applications.

“If the wear characteristics are higher than anticipated in an application, this is where the interchangeability of components plays an important role. Most of our designs allow for interchangeability between metal and rubber components based on specific wear characteristics,” says Koorts.

Warman mill circuit pumps offer standard and low flow liner capabilities, enabling operators to adjust the flow rate as needed without compromising the original installation.

Retrofit optimisations are also available and Weir Minerals Africa says its engineering teams are capable of integrating the Warman mill circuit pumps into existing installations.