+27 (0)11 620 1500

Droste Crescent, Jeppestown, Johannesburg 2043, South Africa

System enhances efficient operation, reliability in pumps

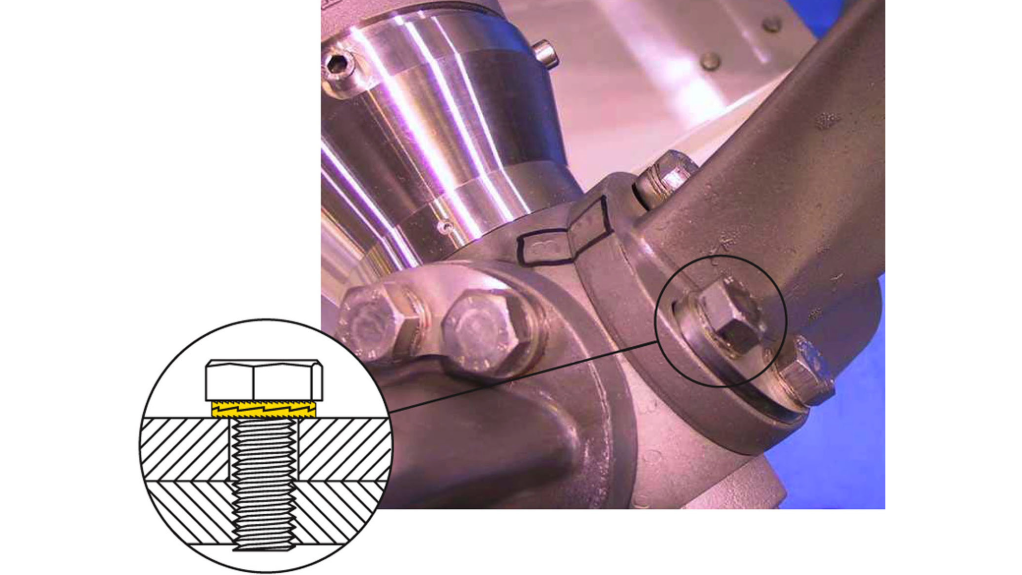

Securing Reliability BMG’s Nord-Lock bolt securing system is used extensively in pumps and pumping equipment to enhance efficient operation and absolute reliability

Industrial equipment supplier BMG, which celebrates 50 years of business this year, says its Nord-Lock bolt securing system is being used extensively in pumps and pumping equipment to enhance efficient operation and absolute reliability.

The system is included in the company’s comprehensive range of quality branded fasteners and related products.

The Nord-Lock bolt securing system uses tension instead of friction to ensure that joints holding sub-assemblies together remain secure, BMG fastener sales manager Maryna Werner says, adding that bolts on pumps need to be easily removable during maintenance procedures, but that they must resist the loosening effects of vibrations and dynamic loads.

“Bolts that are locked conventionally by friction in the thread tend to lose most of their preload through vibrations, while those locked by the tension of this system present a minor loss of preload, which is caused mainly by settlement in the thread. Even after moderate tightening, the bolt is safely locked when using Nord-Lock,” she explains.

Werner adds that it has become increasingly important to have good control of the torque-clamp load relationship when tightening a joint. As such, to optimise the design of the joint and use as much of the capacity of each dimension as possible, she stresses that it is important to know the required tightening torque.

Nord-Lock washers, specifically, are installed in pairs, cam face to cam face, and have a greater rise than the pitch of the bolt. When the bolt and/or nut is tightened, the radial teeth on the opposite side grip and seat the mating surfaces.

The teeth also lock the washers in place, allowing movement only across the face of the cams. The resulting tension makes the bolt self-locking.

These washers can be used on standard and high grade bolts and there is no need for adhesives to lock the stud bolt. This system is designed for use in tapped and counter- bored holes. However, for larger holes or on soft materials, a flange nut or bolt should be used in combination with Nord-lock washers with a larger outer diameter.

Advantages of this re-usable system include maximum safety when locking fasteners, easy assembly and disassembly, positive locking at low or high preload levels and minimum surface marring or scratching, Werner says.

She adds that this system, which has the same temperature characteristics as a standard bolt or nut, resists loosening caused by vibration and dynamic loads. The locking function is not lost by lubrication.

Additionally, she notes that a method for testing the security of a bolted joint is the Junker vibration test, where the preload is measured by a load cell and vibrating motions are generated through the bolt.

The fasteners team provides almost any fastener required, within 24 hours, anywhere in the country and offers a technical advisory and support service through BMG’s national branch network.