Why it is vital to size softstarters carefully

Jaco Brits, Projects and Technical Manager for Drives and Controls at WEG Africa

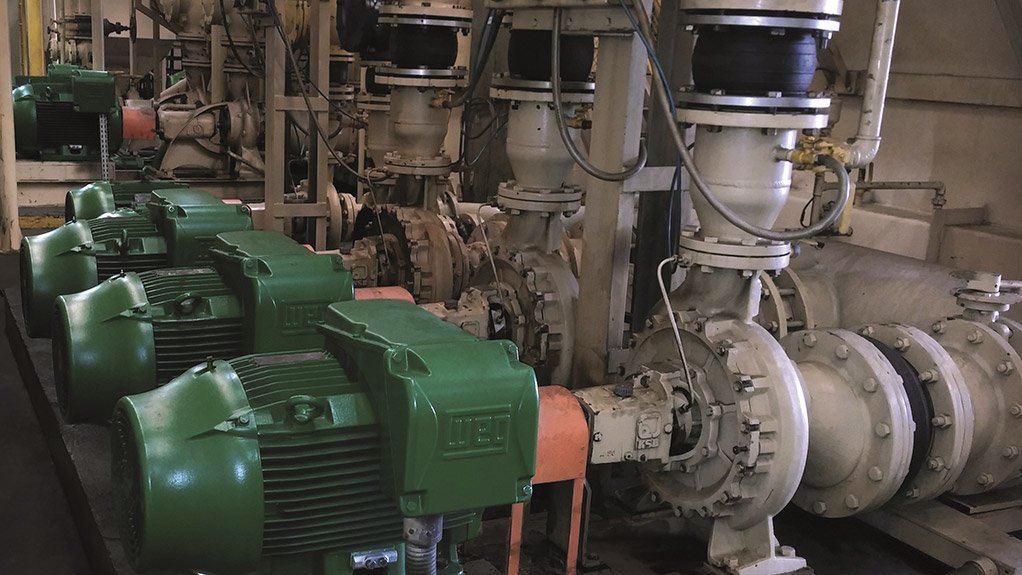

Soft starters are commonly used in pump applications to reduce mechanical stress and ensure smooth efficient motor operation

Close-up view of the WEG SSW7000 medium voltage soft starter HMI, designed for precise motor control and enhanced operational efficiency

The application of soft starters has become a well-established strategy to improve the uptime and lifespan for motors and mechanical equipment driven by motors, but they need to be chosen carefully.

According to Jaco Brits, Projects and Technical Manager for Drives and Controls at WEG Africa, a soft starter protects the motor and the load against mechanical shocks or jolts on startup. It does this, explains Brits, by controlling the voltage that is applied to the motor during startup, thereby reducing the starting current and allowing the gradual acceleration of the load up to the rated speed.

“Properly sizing the soft starter ensures that it can handle the specific motor and load to which it is connected,” he says. “If you under-size the softstarter, it may not adequately reduce the starting current or be able to accelerate the load – resulting in damage to the motor, electrical components or power supply infrastructure.”

Over-sizing a soft starter brings its own problems, as it may exercise less precise control over motor acceleration and deceleration – apart from not being cost efficient.

“Accurate sizing ensures that you are not overspending on a unit larger than necessary,” he points out. “The correct size will deliver a balance between initial investment and long term operational efficiency.”

Brits highlights that the most important factors to consider are the specifications of the motor that the soft starter will be controlling as well as the characteristics of the driven load. The motor’s power rating directly affects the starting current required during motor startup, with higher power motors requiring larger starting currents.

“Motors with different power ratings operate at varying current levels, so the soft starter must be compatible with the motor to ensure proper operation,” he says.

The power rating often correlates with torque requirements, he points out, especially in applications with high torque demands such as conveyors or crushers. In these applications, the soft starter must be capable of providing the necessary torque control during motor startup to achieve smooth acceleration and prevent mechanical stress on the motor and connected equipment.

“Loads will vary widely between applications,” he explains. “Crushers and fans, for instance, may demand enhanced torque control capabilities, while other applications have relatively constant torque demands – like pumps or blowers – which may require soft starters optimised for efficient energy usage rather than enhanced torque control.”

Some soft starters offer adjustable torque profiles or advanced algorithms to optimise torque delivery based on the load type. Another aspect that varies from one application to the next is the acceleration and deceleration profiles.

“The user might also have some specific needs for overload protection,” says Brits. “Other types of motor protection may also be considered, such as phase imbalance detection, undercurrent protection and over-temperature protection.”

The soft starter also needs to be compatible with the control systems in place – such as Programmable Logic Controllers (PLCs) or Supervisory Control and Data Acquisition (SCADA) systems.

“To support customers in understanding more about soft starter technology and sizing, WEG Africa offers a range of resources and training opportunities,” says Brits. “Our technical team is on hand to examine customers’ applications and answer questions about size selection, installation and troubleshooting.”