Why your High Pressure Grinding Roll needs to skew

Standfirst

Weir Minerals argues that skewing is a vital feature for modern High Pressure Grinding Rolls, reducing wear and ensuring optimal grinding across the whole feed, saving energy downstream. Weir Minerals shares the findings of our new white paper.

With their excellent throughput capacity, low maintenance requirements and energy efficiency, High Pressure Grinding Rolls (HPGRs) are fast becoming a go-to for greenfield projects looking to maintain their margins despite commodity price pressures and declining ore grades.

“In service since the mid-eighties and used primarily in cement production, HPGRs are increasingly being deployed as tertiary and quaternary crushers in mineral comminution circuits, dealing with tougher ores including iron, gold, copper and diamonds,” says Henning Knapp, HPGR Process Team Leader for Weir Minerals.

“As any engineer will tell you, it’s almost impossible to eliminate feed variance and segregation completely. In the past, this has posed a critical challenge for HPGR operators – but dynamic skewing such as that featured in the Enduron HPGR maintains optimal pressure across the entire feed.”

Traditionally, HPGR manufacturers have shied away from skewing designs, for fear of roller misalignment creating unfavourable load distributions, and preventing the use of flanged guards to reduce the edge effect. However, Weir Minerals’ unique roller bearings design allows for skewing alongside effective edge guards, reducing wear and promoting better grinding.

The downside of static rollers

A HPGR reduces particles by compressing and crushing the feed between two equally sized, parallel rollers rotating in opposite directions, with a small gap between them. This compresses the feed to 80% of its solid density, where the force of the rollers pushes the rocks against each other and exceeds their compressive strength.

“Inter-particle comminution avoids the direct component wear caused by conventional comminution techniques, and applies immense pressure, up to 27,000kN, across the entire particle size distribution, which creates the higher proportion of fines HPGRs are renowned for,” says Knapp.

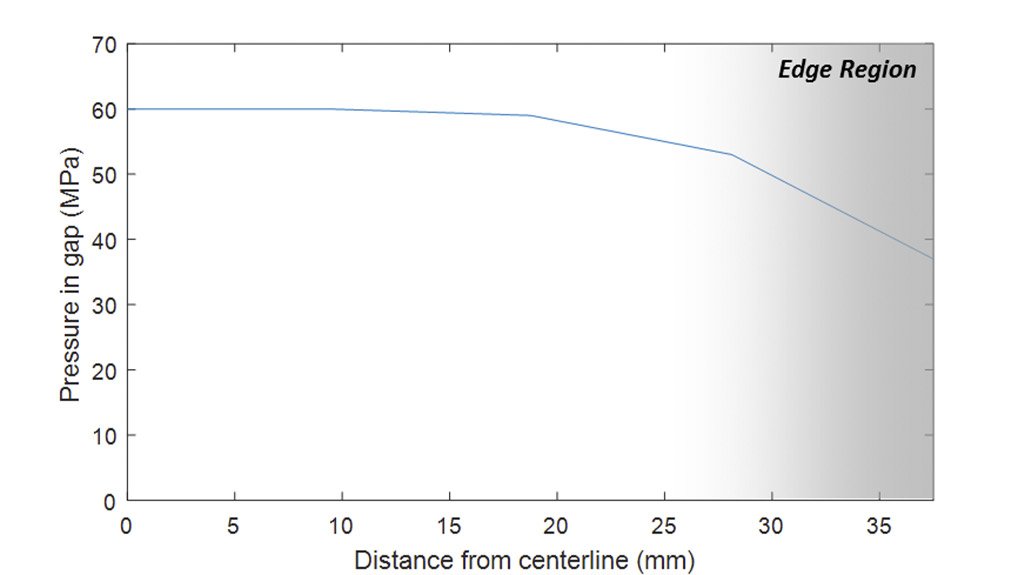

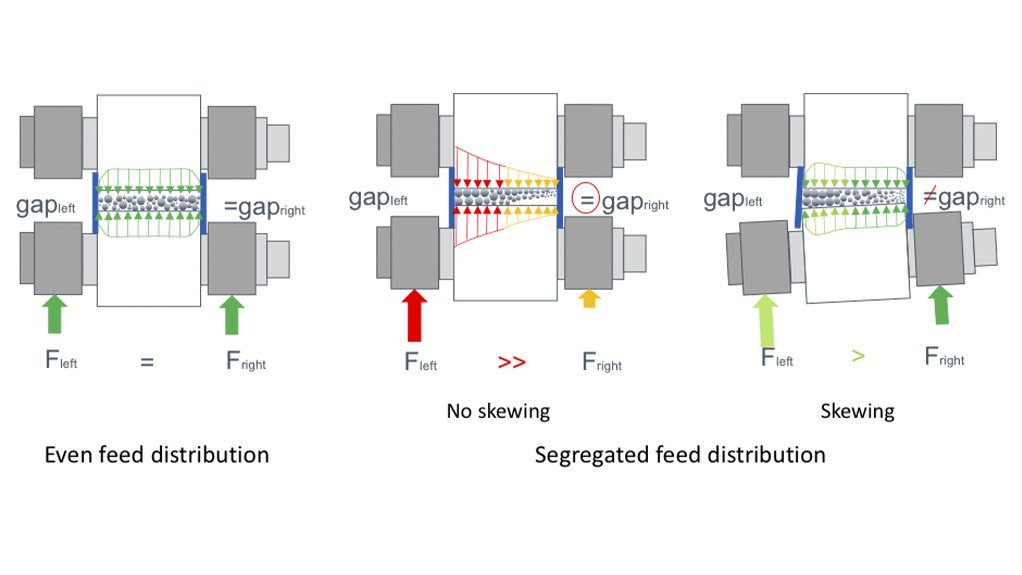

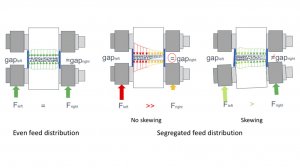

However, segregated feeds can result in markedly uneven particle sizes across the width of the feed, creating high, abrasive pressure on one side of the roll and insufficient pressure on the other. It will also produce a coarser product, requiring more work downstream.

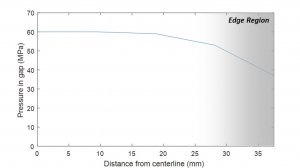

“To compensate for the edge effect, a lateral wall or ‘cheek plate’ is deployed on either side to prevent material exiting the gap between the rollers sideways. The closer this is to the rollers, the better – but that has prevented engineers from introducing the flexibility needed to cope with feed segregation,” explains Knapp.

How Enduron® HPGRs skew to maintain optimum pressure

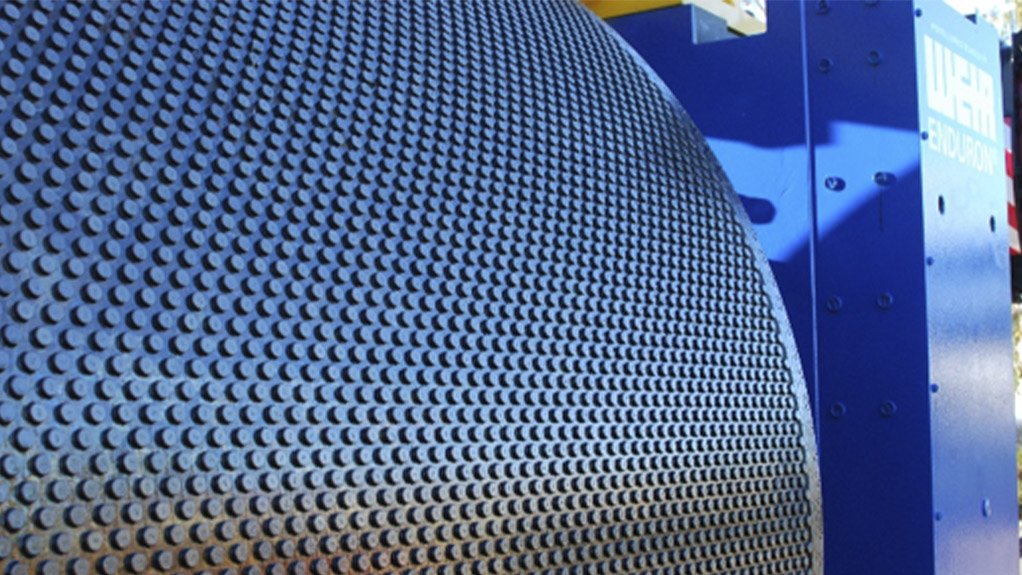

To accommodate this uneven pressure Enduron® High Pressure Grinding Rolls utilise a unique spring-loaded lateral wall which not only reduces the edge effect (maintaining a gap of as little as 1mm) but is specifically designed to facilitate roll skew.

As shown above, an uneven feed will lead to high pressure on one side and not enough on the other. Having one roller skew will facilitate larger material at one end while ensuring the smaller particles on the other side receive enough pressure to be ground down.

Simply, it maintains an even pressure distribution across the entire feed, saving energy and reducing wear.

“The degree to which the Enduron HPGRs skew is largely dependent on the width of the roll, with longer rolls skewing about 5mm for every metre the roll is wide. However, the effect of even small changes can be significant on local pressure peaks,” says Knapp.

“The skewing should be managed by an advanced control system, which steers the rolls to satisfy the desired output pressure. This system also ensures the skew isn’t too great or maintained for too long, which both disrupt the compressive bed.”

In the case of prolonged or excessive skewing, Enduron® HPGRs send a signal notifying the supervising control system and operating staff. Prolonged skewing generally is indicative of a disturbance or fault in up-stream facilities, such as low bunker filling, upstream crusher wear, screen deck wear, or conveyor failure.

Where static rolls suffer from differential pressure, creating undesired product, consuming more energy and suffering additional wear, Enduron® HPGRs maintain optimum pressure across the entire feed thanks to their skewing, spring-loaded lateral walls.

“When dealing with competent mineral feeds in real-world conditions, there’s simply no substitute for the Enduron HPGR’s ability to maximise performance with skewing,” concludes Knapp.

Dynamic skewing is just one way Enduron® HPGRs stand out from the competition.

Weir Minerals Africa