Barloworld showcases R68m investments in its Rebuild Centre

Completed rebuilt components ready for dispatch

Photo by Schalk Burger

Automated repair robot

Photo by Schalk Burger

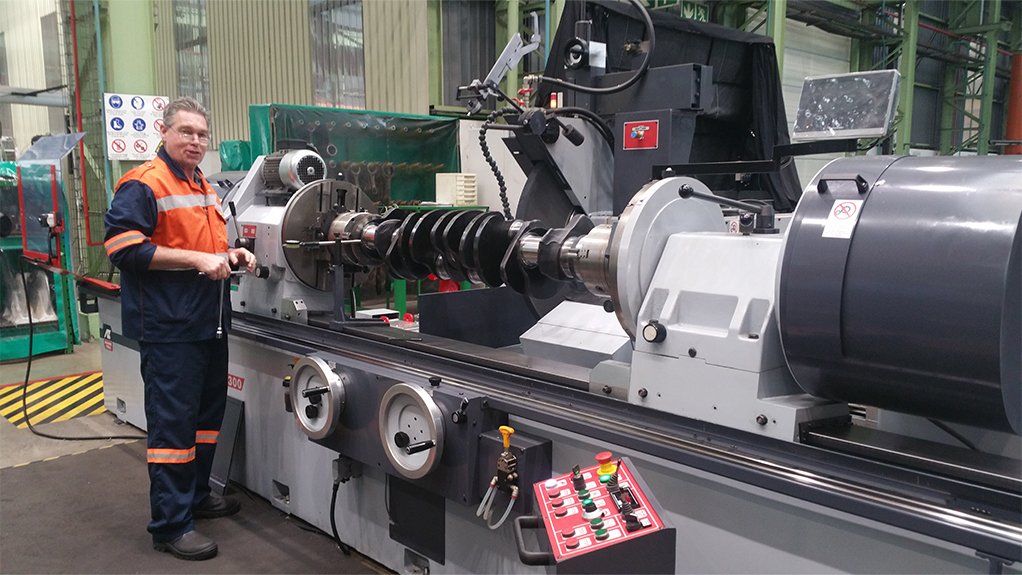

The BRC's new machine that can repair crank shafts down to micron-scale tolerances

Photo by Schalk Burger

The BRC's new engine-block machine can perform all the work orders it needs, and eliminating outsourcing of work

Photo by Schalk Burger

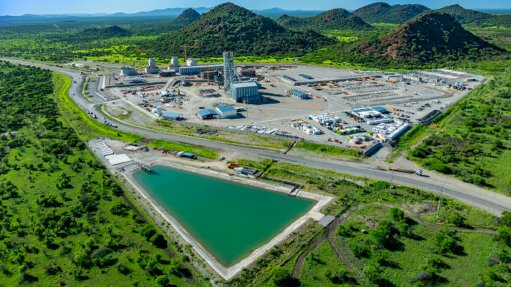

Industrial equipment and services company Barloworld on November 11 took media on a tour of its Rebuild Centre, which completes an average of 2 000 rebuilds a year of components and engines for earthmoving equipment manufacturer Caterpillar’s mining and construction-related machines.

The centre, in Ekurhuleni, Gauteng, supported more than 24 000 assets in the Southern African region, mostly used for mining, and rebuilt components from Angola, Botswana, Malawi, Mozambique, Zambia and Zimbabwe, as well as sometimes from the Democratic Republic of Congo, said Barloworld business excellence executive head Kamogelo Mmutlana.

Barloworld provided technical support and ensured parts were available for these assets to ensure the mean time to repair was shortened. The philosophy of the group, and for the Barloworld Rebuild Centre (BRC), was to get progressively better at keeping the assets of customers available and working, he said.

The centre was opened in 2012 and the company has made continuous investments to bolster its capabilities. The company has 11 other smaller component refurbishing centres throughout Southern Africa, but the BRC repairs the largest components and also serves as the main hub for its repair and support services.

Most recently, Barloworld had invested R68-million into new smart equipment at the BRC, which could replicate specific jobs, after being set up once. The next step would be an investment into smart tooling for its artisans and technicians.

The smart tools would not only log all data, to be analysed for operational, quality and customer requirements, but would also reduce the strain on technicians and, once a work order had been programmed in, the tool would be able to replicate the work order, thereby increasing accuracy, he said.

Further, the BRC re-manufactures the components and engines back to Caterpillar specifications. Caterpillar shares the specifications of the machines with the BRC, meaning the components are Caterpillar-certified, and customers can secure full warranties for the components they buy from the centre.

“By the time the component finds its way here, it has typically reached the end of its economic lifecycle. Traditionally, these would be disposed of and replaced, but, in this case, we have the technology and capabilities to re-manufacture them,” explained Mmutlana.

“The fact that the centre focuses only on Caterpillar-made equipment means that it can provide the quality and turnaround times required by customers,” he added.

The BRC provides rebuilt replacement components that customers can buy, unless they prefer that the centre rebuild their components.

Components that had failed in the field and that the customer did not want to exchange for a replacement, were prioritised for repairs; effectively jumping the queue, he noted.

“We sometimes receive components from major failures on a Friday evening and the team immediately starts stripping and repairing it to ensure the component and the machine is back in operation by Monday, if not earlier,” Mmutlana said.

Additionally, as Caterpillar's technology evolves and improves, more connected machines are in the field that the BRC can monitor for performance and thereby predict failures and advise clients to intervene before the damage becomes worse.

Therefore, it was imperative for the company and the BRC to continuously improve the skill-sets of its technicians to keep pace with the new technology offerings Caterpillar was putting into the market, he added.

Barloworld works closely with the original-equipment manufacturer to increase the pool of technicians.

Once technicians have achieved the Cat certification, they became a premium commodity. It was a constant challenge to ensure the BRC had technicians equal to the demands placed on them, and to ensure it remained agile and capable of responding to customer demands, said Mmutlana.

Further, while mathematics and science were subjects traditionally required for technician work, the company was looking at a train-to-task approach where the technician followed a clear and well-designed process for disassembly and assembly of a component.

“We aim to introduce this and we think it will help us to onboard more technicians who are technically inclined, but do not have the traditional subjects to train as a technician, and who could then aim to gain further experience and skills in the manufacturing industry,” he said.

Barloworld is also planning to make further investments, in addition to the R68-million investment into smart equipment, to digitise the BRC's operations from production planning to execution.

“We are optimistic about the future, partly owing to the opportunities in the construction of energy and electricity infrastructure in Africa. As Barloworld equipment, we aim to seed more machines into the market and we expect the business to continue to grow, supported by the BRC here,” Mmutlana said.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation