Company offers software system to manage PPE across industries

Health and safety solutions group Bramhope is offering a first-of-its-kind software system that measures, assesses, evaluates and manages personal protective equipment (PPE) free of charge to contracted customers.

“Since the system’s initial launch in 2007, many improvements have been introduced. It continues to be a dynamic system that is being developed and expanded as more data becomes available to be analysed and built into the system to ensure accuracy, efficiency and improved functionality,” says Bramhope Group CEO Isak Marais.

Last year, this cloud-based management platform was listed in the 2015 Accenture Innovation Index as a Top 100 most innovative company. The company is also in contention for this year’s Top 100 award.

“Interest in the software system is growing as economic pressures are still looming and companies are forced to consider systems to ensure total cost of ownership (TCO) of PPE items is even further reduced,” adds Marais.

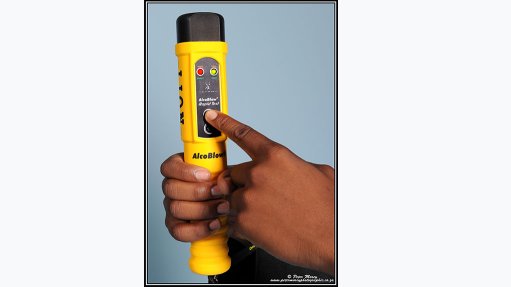

Bramhope’s PPE management system leads to increased item life span, optimised use and safer workplaces. The benefits include real-time reporting for each item, and user, location and job profile, with the system also accurately determining the selection of PPE by weighing employee profiles against unique workplace risks, specific work areas and user trends.

The company notes that it is the only system proven to reduce TCO by up to 50%, as it controls all aspects of PPE, including the issuing, use, application and calibration of a company’s PPE, training on equipment, product information versus job specification – employee profiles are analysed to ensure the correct PPE is issued – and stock control.

The system features a built-in global sourcing platform, ensuring secure access and a large, searchable database of suppliers, making it accessible “to any company, in any industry, in any country”, highlights Marais.

The company further explains that, on average, companies will spend R2 000 a year on PPE for each employee, without factoring in costs incurred through theft and damages. He notes that, by developing and implementing effective PPE management structures, customers can now further reduce the TCO while reducing risk.

“We continuously apply innovation to assist customers in simplifying and streamlining their processes through applying cutting-edge technology. We develop, source and provide quality products, value-adding services and customised solutions that help companies and individuals implement, manage and maintain healthy living and safe working environments.”

Marais points out that the company is no longer just a seller and distributor of PPE, with its omnichannel approach delivering comprehensive and cost-saving solutions across multiple technologies, platforms and media. He adds that the company wants its customers to benefit from all its offerings.

“We want to demonstrate how easy it can be to manage PPE effectively and how much companies can save using our system. The only way to do this is to let our customers use our system and see the results for themselves.”

He maintains that although PPE is one of the least preferred methods of risk reduction at some companies, it is also one of the most important. The popularity of PPE is sometimes downplayed, as employers do not have control over it and this results in financial losses, which they are not prepared to take. These costs can be reduced significantly if the employer has full control over the sourcing, procurement, items issued, use and management of all PPE items in an effective way.

Marais advises that companies need to source PPE management systems strategically, as there is a myriad of choices in the PPE industry. However, without a management system, spending can quickly get out of control, leading to increased costs and inconsistent levels of protection and waste.

“As far as we know, there is no similar system in South Africa that is cloud-based which manages the full cycle of PPE management, which guarantees reduced TCO of PPE and other safety items,” concludes Marais.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation