Deadline for heavy-metal-free PVC pipes approaches

PENALTIES FOR NONCOMPLIANCE Companies found to be noncompliant could have steps taken against them by the South African Bureau of Standards

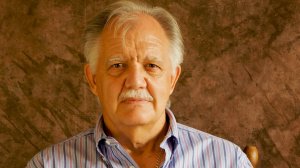

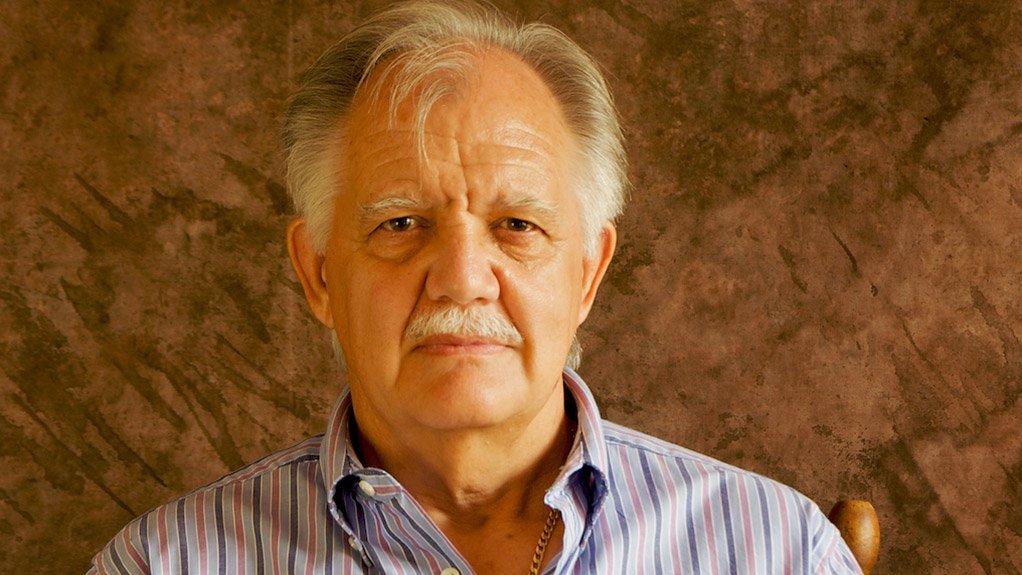

JAN VENTER The Southern African Plastic Pipe Manufacturers Association urges all local pipe manufacturing companies to comply with the new regulations

Local manufacturers of polyvinyl chloride (PVC) pipes have only six months left to ensure that their products are compliant with provider of standards, management systems, business improvement and regulatory approval information the South African Bureau of Standards (SABS) ruling that all locally manufactured pipes be free of heavy metals by July 31.

This ruling was announced by SABS Certification Gauteng GM Sibongile Dhlamini on October 30, 2013, following an amendment of a series of standards by the technical committee of the SABS Standards Division.

Industry body Southern African Plastic Pipe Manufacturers Association (Sappma), which represents more than 80% of the country’s pipes manufacturers, highlights that it welcomed this announcement.

Further, Sappma chairperson Jan Venter tells Engineering News that the SABS gave local manufacturers of PVC pipes, who are SABS-certified, a window period of 24 months to realign their operations to comply with the new standard requirements.

However, after the deadlines, noncompliant companies could see steps taken against them by the SABS.

Venter states that pipes bearing the SABS mark of quality will also have to be resubmitted for testing to be issued with new permits.

“In the interest of the consumer and good business practice, the SABS strongly promotes the highest possible product quality standards, as well as environment- friendly manufacturing processes and materials,” he states.

Therefore, Sappma urges all local pipe manufacturers to ensure they comply and that all heavy metals are removed from the manufacturing process.

Sappma Members Lead Compliance Race

Sappma’s aim is to support the industry in promoting quality products, which has seen the association work closely with the SABS in matters of standards and quality through the implementation of various quality- assurance measures and initiatives, as well as by demanding additional good practice measures from Sappma members.

Venter adds that Sappma’s members already embarked on a voluntary removal of heavy-metal stabilisers from their PVC pipes since 2006.

“The policy was fully implemented by Sappma in July 2009 and applied to drinking water system pipes as well as sewer, drainage and mine pipes,” Venter points out.

He explains that, although lead does not leach from the plastic pipes and does not pose any danger to people once installed, Sappma felt compelled to create a safer environment for the manufacturers, where lead poisoning poses a risk for their workers.

As a result, all PVC pipes manufactured by Sappma members are lead-free and are stabilised with environment-friendly materials, such as calcium-zinc or organic-based stabilisers.

“Removing heavy metals from companies’ PVC pipes was done at considerable cost to our members, but was wholly supported as it was in line with Sappma’s life cycle thinking. This took end-of-life issues and waste management options into account and was based on health and environmental considerations,” Venter points out.

Further, he says that the adherence to the policy has been a requirement for Sappma membership since 2006.

“This policy also forms part of the regular Sappma factory audits,” Venter concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation