Delba Electrical Field Services for electrical rotating machines

Enhancing customer satisfaction: Unleashing the power of Delba Electrical’s field service capabilities for electrical motors

In today's fast-paced and technology-driven world, Delba Electrical is constantly seeking innovative ways to improve on customer service. For Delba Electrical, which is involved in the electrical motors industry, one of the most critical aspects of ensuring customer satisfaction is providing exceptional field service capabilities. Field services play a pivotal role in supporting customers throughout the lifecycle of their electrical motors, from installation to maintenance and repair. By leveraging advanced techniques and a customer-centric approach, Delba Electrical can deliver unparalleled support, maximise uptime, and foster long-term partnerships.

Installation Excellence: Getting it Right from the Start

The installation phase sets the foundation for the optimal performance of electrical motors. Recognising the significance of this stage, Delba Electrical invests in highly skilled field service technicians that are well-versed in motor installations. Our technicians possess a deep understanding of electrical motor systems, ensuring every aspect of the installation process is carried out meticulously.

The installation phase includes:

- Installation of rotating machine

- Laser alignment

- Connection of electrical circuit

- Onsite balancing

- Vibration diagnostics

- Partial discharged measurements

- Electrical testing

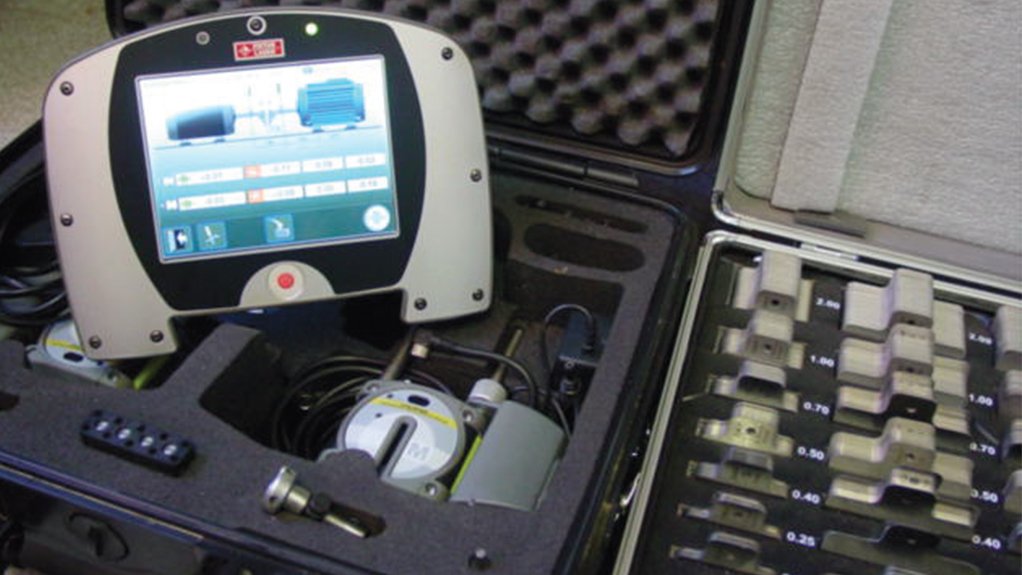

Our field service technicians bring their expertise to ensure seamless installations. Delba Electrical’s field service technicians use specialised equipment and follow industry standards to guarantee that the motor is correctly integrated into the customer's equipment or machinery. By prioritising accuracy and precision during installation, Delba Electrical reduces potential risks and ensures the longevity of the motor.

Preventive Maintenance: Nurturing Longevity and Performance

Regular maintenance is essential for the sustained performance of electrical motors. Our field service capabilities extend beyond the initial installation to encompass comprehensive preventive maintenance programmes.

Proactive measures include:

- Insulation resistance test on rotors, stators and exciters

- Polarisation index (PI) test on stators and rotors

- Bearing inspections (top and journal clearances) as well as insulation resistance test to earth

- Cleaning of rotor and stator by means of non-flash chemicals and dry ice cleaning.

- Thermal imaging

- Motor data logging

- Current signature analysis testing

- Motor dry ice cleaning

- Brush gear inspection as well as kick-neutral settings

- Inspection on windings of stator and rotor

- Inspection of armature and commutator

- Vibration diagnostics

- Motor management through continuous monitoring improvement programme

Such periodic inspections, lubrication and cleaning not only enhance motor efficiency but also help identify potential problems before they escalate into critical failures.

Our field service technicians always conduct thorough inspections to assess the condition of components, identify wear and tear, and detect any signs of abnormal operation. They utilise advanced diagnostic tools and techniques to measure key parameters such as vibration, temperature and electrical performance. Based on these assessments, our technicians make data-driven recommendations for maintenance and replacement of worn-out parts, ensuring optimal motor performance and reliability.

Rapid Response Repairs: Minimising Downtime and Maximising Productivity

Despite meticulous maintenance efforts, unforeseen breakdowns can occur. During such critical moments, our responsive field service capabilities become indispensable. Our equipped and well-coordinated skilled technicians can swiftly be deployed to customer sites, minimising downtime and optimising productivity.

Our field service technicians adeptly diagnose motor failures and employ their expertise to troubleshoot problems efficiently. They carry a range of spare parts and tools, enabling them to perform on-site repairs promptly. By resolving issues in a timely manner, our technicians contribute significantly to reducing production disruptions and associated costs.

Further, in situations where repairs cannot be carried out immediately, our field service technicians facilitate efficient motor removal, transportation and subsequent workshop repairs. These comprehensive capabilities ensure that customers experience minimal disruption and receive the necessary support to restore their operations swiftly.

Cas Sulaiman

Mobile: +27 76 820 5233

e-mail: cass@delba.co.za

Web: http://www.delba.co.za/

Danie Janse van Vuuren

Mobile: +27 82 349 0097

e-mail: daniej@delba.co.za

Dirk van Vuuren | Sales Manager

Mobile: +27 82 563 2338

e-mail: dirk@delba.co.za

Theo Pienaar | Sales and Services Africa

Mobile: +27 82 777 0618

e-mail: theop@delba.co.za |

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation