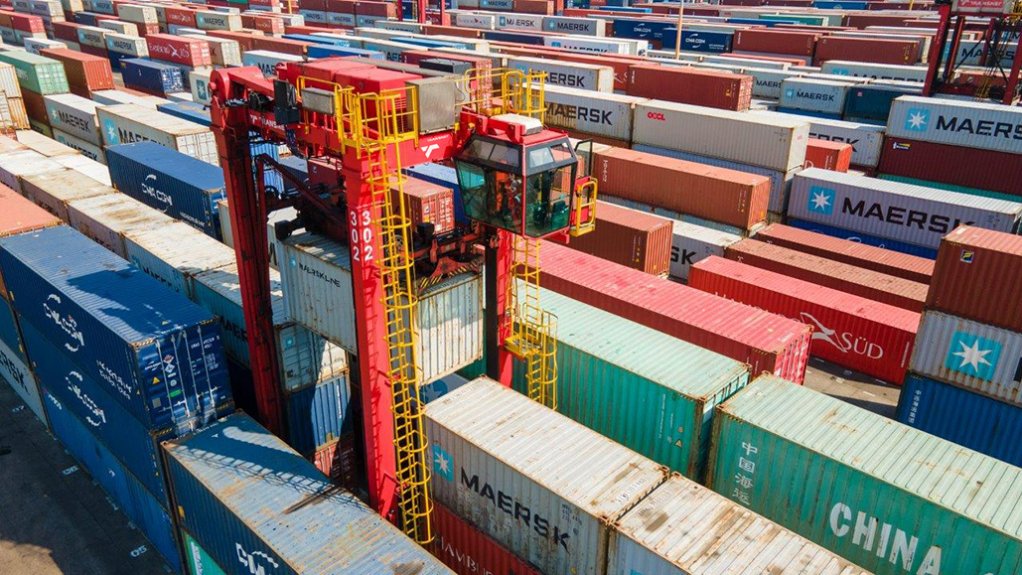

Durban Container Terminal increases working hours to clear backlog, amongst other measures

The Durban Container Terminal (DCT) Pier 2 has increased the ship working hours at some of its berths over the last few days to clear the backlog of vessels at anchor, Durban Terminals has revealed.

Over three consecutive days, berth 204 of the Transnet Port Terminals- (TPT-) operated port terminal has been performing above the set ship working hour target across all three shifts, handling up to 28% more volume than previously planned.

“As we move things around, eliminate waste and employ diversion strategies for cargo to be serviced at our other Durban terminals, while we finalise and conclude the awarding of contracts for spares and maintenance, our employees have been catalysts in the clearing of vessels as they witness mounting frustration from the country,” Durban Terminals managing executive Earle Peters said on November 30.

He added that, while equipment and weather still presented challenges, employee commitment had made all the difference.

“In a situation like this, it’s really not about what you have but what you do with what you have. And for our employees to find their role in this complex challenge has been extraordinary,” he said.

There are currently 52 vessels at the Port of Durban’s outer anchorage, while a total of 18 vessels are destined for the DCT Pier 2, with 24 431 import containers.

Durban Terminals emphasised that not all the vessels anchored outside the Port of Durban were destined for the DCT, but were rather destined for privately-owned facilities, and it was therefore incorrect to interpret the total number of offshore vessels as an indication of the specific congestion at DCT Pier 2.

Peters said this needed to be borne in mind in any assessment of the congestion at TPT facilities.

According to current plans and set targets in line with available equipment, it would take Pier 2 about 14 weeks to clear the backlog. However, TPT said there were many parallel efforts aimed at reducing this time.

Peters said that, through the help of one of the customers, the Durban Multipurpose Terminal (DMT) took delivery of three reach stackers last week. He said this was significant because some of the container vessels destined for DCT Pier 2 were diverted to the DMT.

In the meantime, DCT Pier 2 will continue sourcing additional cargo handling equipment from customers and the market at large as a temporary measure in the interim.

A spares and maintenance services contract for the existing equipment, namely ship-to-shore cranes, rubber-tyred gantry cranes, straddle carriers, reach stackers and empty container handlers is also in the process of being awarded, with delivery of service expected soon. A 24-hour maintenance regime has also begun to secure the availability and reliability of existing equipment.

The implementation of an original-equipment manufacturers strategy for the acquisition of container handling equipment over the next ten years and the asset life cycle management over the next 20 years have also been finalised. Letters of award will be issued in the next three weeks, Peters said.

TPT manages a network of 16 sea-cargo and three inland terminals nationally, and besides the DCT and the Richards Bay Bulk Terminal, Peters said the situation at the other nine sea-cargo terminals remained fluid.

“We are making steady progress in dealing with the congestion and would like to assure our customers – and the public in general – that we are fully focused on ensuring minimum disruption to festive season supply lines for imported products, and in ensuring improved access for export products too,” Peters said.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation