Hydrox nearing commercialisation of hydrogen technology, opportunities abound for saving curtailed energy

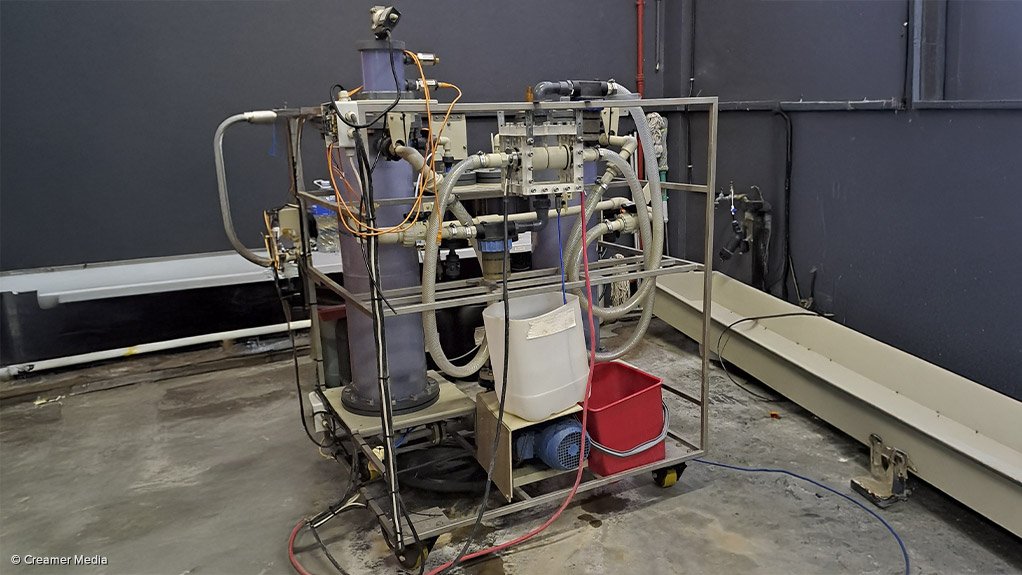

Test unit

Photo by Creamer Media's Tasneem Bulbulia

From left to right: Dr Valantine Lukong (UJ), Dr Peter Oviroh (UJ), Corrie Jager (Hydrox), Prof Tien-Chien Jen (UJ), George Anagnostopoulos (Hydrox), Nolufefe Shezi (UJ), John Masamvu (UJ), and Kulani Mageza (UJ)

Photo by Creamer Media's Tasneem Bulbulia

Hydrox Holdings CEO Corrie de Jager showcases the technology

Photo by Creamer Media's Tasneem Bulbulia

Hydrogen technology company Hydrox Holdings is progressing the development of its pioneer Divergent-Electrode-Flow-Through (DEFT) hydrogen technology, a membrane-less electrolyser, with the company advocating this as a viable, cost-effective storage solution for curtailed energy.

Developing this patented technology forms part of the company’s efforts to bring down the cost of hydrogen, to make the hydrogen economy viable.

CEO Corrie de Jager tells Mining Weekly in an exclusive interview that Hydrox is building a prototype demonstration unit of the technology, which is expected to be completed within the next three to four months.

It will then scale up the solution, before conducting rigorous testing by running it for about 2 000 continuous hours and applying for the requisite certification. It anticipates completing these steps within a year, after which commercialisation will start.

This milestone will follow a 25-year development process.

Initial funding was provided by chemicals company Shell; however, development of the technology was temporarily halted in 2022 owing to challenges in securing additional funding required for further work.

De Jager expresses frustration in obtaining development funding, noting that venture capital funds, and even entities like the Industrial Development Corporation, are “risk averse” and require bankable projects with fixed return on investments, making it difficult for the company, which is still in the development phase, to leverage these funding mechanisms.

However, he expects that, once the demonstration model is complete, more funding opportunities may arise.

HYDROGEN STORAGE SOLUTION

De Jager acclaims that the DEFT technology provides an “innovative solution” for using curtailed “free” or “wasted” energy.

He points out that there is a proliferation of renewable energy globally, but the electricity transmission networks are congested and cannot accommodate this volume. Building new transmission lines will take time, while other storage solutions are costly and/or ineffective.

University of Johannesburg (UJ) Department of Mechanical Engineering Engineering and the Built Environment's Professor Tien-Chien Jen, who also partook in the interview, says that this challenge is especially prevalent in the global south, which is less industrialised, leading to energy generated from burgeoning renewable-energy sources being wasted.

Jen acclaims, therefore, that hydrogen can play a significant role in the region for energy storage and transport.

However, the cost of electrolysers is very high, with De Jager estimating costs for a high-quality proton exchange membrane (PEM) electrolyser at about $2-million for a 1 MW unit. Moreover, these PEM electrolysers also have “serious maintenance issues”, which compounds the costs.

He explains that PEMs are more energy efficient than alkaline electrolysers; however, the latter are more robust.

The DEFT technology uses an alkaline system but it is unique in that the company’s technology has eliminated the need for a membrane, a core component, which delivers costs savings and considerable potential, De Jager says.

Moreover, this technology requires less maintenance and removes the risk of the membrane being compromised and the plant coming to a standstill.

De Jager says the technology is most suitable for curtailed energy, as only one compact unit can operate at high current densities delivering huge volumes of hydrogen, considerably reducing the capital cost.

He explains that the cost of hydrogen production in general is determined by two factors: the cost of electricity (about 75%) and the cost of an electrolyser, its maintenance and replacement (about 25%).

“The main cost factor is the electricity cost and, if this is high, hydrogen will not be cost effective. With curtailed ‘free energy’, the majority of the cost falls away. This is a game changer.”

De Jager explains that the technology can be used for curtailed energy because the simplicity of the membrane-less system and its unique flow-through operation means that it is capable of handling extreme current densities.

He points out that other electrolysers are limited in their current densities because of the formation of bubbles and the brittleness of the membrane. “The more bubbles there are, the more activity on the two electrodes, and the more the membrane can be affected, potentially causing it to crack or erode.”

The company’s high current density tests achieved 20 A/cm2, which is 30 times better than the current available alkaline electrolysers, De Jager explains.

Therefore, one of the company’s units would be equivalent to 30 alternative electrolysers which, at about $2-million apiece, would cost millions. By comparison, Hydrox is optimistic its unit will cost about $800 000, he says.

Moreover, a relatively small unit, operating on only six hours of curtailed energy at 30 MW, can produce 3 000 kg/d of hydrogen, De Jager notes. This would mean that the $800 000 capital cost could be paid off in 133 days, and is effectively free for the next two decades and more.

“It’s a revolutionary way of saving energy,” De Jager says, adding that, despite the unit being energy inefficient compared with other electrolysers, this is negated by its low capital cost.

STRONG PARTNERSHIPS

De Jager also highlights the company’s entrenched partnership with UJ, which it will continue to leverage, and look to bolster, as it develops this technology.

Jen indicated that the university wants to partner with Hydrox in this development, as the university’s “cutting-edge technology” provides the scope to enhance the electrolyser’s components, presenting a “win-win” collaboration situation.

Jen was also recently appointed as Research Chair in Green Hydrogen at UJ.

Moreover, De Jager says the company is also exploring the potential of moving its operations from the current Randburg location to UJ’s facilities, which would provide a bigger space with access to all the equipment it requires, as well as allowing it to easily leverage the skills and expertise of the requisite students.

Hydrox would also look to capitalise on the academic expertise of the university, to solve the practical challenges faced with the technology.

Meanwhile, De Jager further mentions that the quality of the technology is reflected in Hydrox scooping up several awards in recent years.

Moreover, it is also underpinned by keen international interest, with De Jager confident that the company will be able to secure orders once commercialisation is achieved.

He cites an interaction at a recent European hydrogen seminar where the company presented its technology, with a Norwegian scientist requesting a cost-effective electrolyser that is capable of producing high volumes of hydrogen, owing to the country’s challenges with curtailed energy.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation