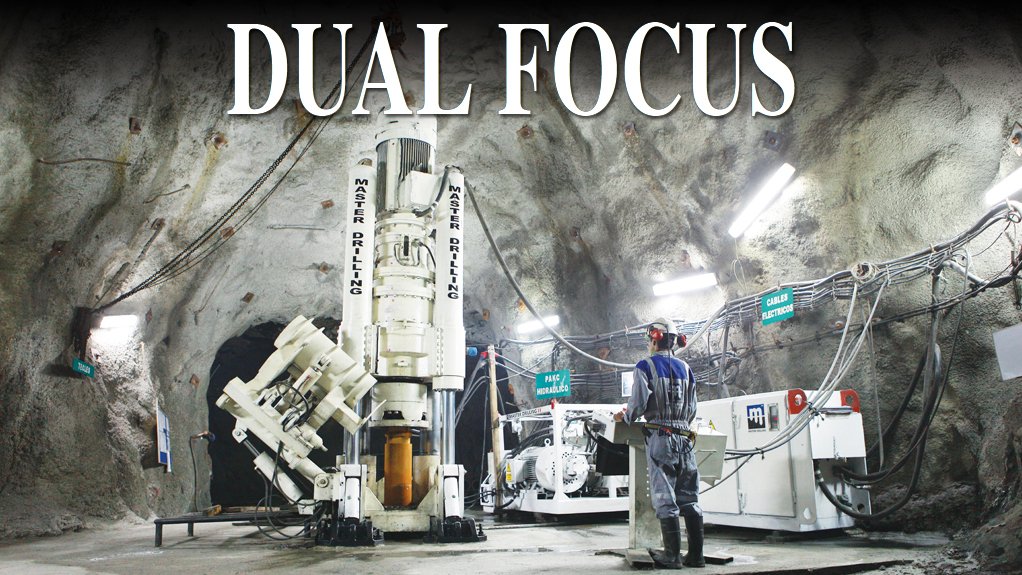

Master Drilling earmarks ‘significant share’ of capex for product portfolio, market diversification

READY TO ROCK Master Drilling’s recently developed MTB – manufactured for horizontal mining applications – is ready for market

DANIE PRETORIUS Master Drilling is about selling a solution and not a product. Our technologies are the result of identifying and responding to needs in the market - ahead of the curve

KOOS JORDAAN Master Drilling is confident that its MTB will be contracted to a project within the next three to four months

JOHANNESBURG (miningweekly.com) – Having grown from strength to strength since its JSE listing in 2012, local innovative drilling solutions provider Master Drilling plans to focus its capital expenditure (capex) on product and market diversification over the next five years, according to group CEO and founder Danie Pretorius.

He tells Mining Weekly: “While the backbone of Master Drilling has always been focused on raiseboring – a fact that the group does not anticipate will change soon – horizontal boring, mobile tunnel boring (MTB), shaft drilling and a serious drive towards the development of automated continuous rock-cutting equipment will become a main focus for the group going forward.”

To this end, he adds, the company plans to invest a significant share of its capex in horizontal boring technology development over the next five years.

“This decision is a strategic one. There is significant demand for horizontal boring in the mining industry, as well as in other industries, such as the civils sector and the energy sector,” enthuses Pretorius. He reveals that, through the company’s increased investment into horizontal boring technology, Master Drilling hopes to appeal more strongly to other sectors, as well as strengthen its foothold in the future of mining.

Pretorius states that MTB will become a critical element of the mining industry as miners attempt to extend the life-of-mine of their operations. The reason for investing in these nonblasting cutting-edge technologies is that mining houses are looking to safely reach deeper orebodies at existing mines a lot faster, and Master Drilling will thus assist its clients in clearing the net present value hurdle. He further says that this disruptive technology allows continuous mining and requires no blasting, thereby significantly enhancing mining efficiencies. It is as advantageous at the capital stage of mining projects – with quicker deployment and access to the orebody – as it is at the production stage, where it results in substantial productivity increases and a decrease in operating costs.

Pretorius says the company’s current horizontal boring service offerings already include the potential for lower support requirements than tunnels excavated by means of conventional drill-and-blast methods, which often damage the tunnel walls, thus compromising the safety of an operation. The continuous excavating cycle and the circular structure of the excavation leave a stronger profile tunnel and ensure higher mine productivity, as miners can reach new orebodies in the fastest possible time. He adds that horizontal boring operations are safe, quick and easy to implement. He indicates that, while horizontal boring may not be the optimal solution for every mine’s needs, the technology is more cost effective, and in most cases a more reliable solution.

“Master Drilling is about selling a solution and not a product. Our technologies are the result of identifying and responding to needs in the market – ahead of the curve,” says Pretorius.

In line with the company’s goal to diversify it capabilities, Master Drilling executive director Koos Jordaan states that the company’s recently developed MTB machine – manufactured for horizontal mining applications – is ready for market introduction.

“Master Drilling has noted significant interest in the MTB technology from about 15 top global miners, who recognise the potential impact that this ‘disruptive’ technology could have on their bottom line,” Jordaan says.

He adds that, owing to the significant interest already shown in the new technology, the company anticipates that the system will be contracted to a project by the first quarter of 2019. If the system is not officially contracted to a project by early next year, he says, the company will further demonstrate its capabilities by allowing it to run on a trial basis at an interested mining operation.

“At this stage, however, given the interest that has been demonstrated by the market, Master Drilling is confident that this technology will be contracted to a project within the next three to four months,” Jordaan emphasises.

The MTB system is specifically designed for horizontal and inclined hard-rock applications, eliminating the need for conventional tunnel drilling and blasting. The system’s high level of automation allows Master Drilling to excavate tunnels with a smooth circular cross section, safely and cost effectively.

While similar tunnel boring methods are used in civils- and energy-related projects, the novelty of the MTB technology relates to its ability to be efficiently used in mines, which requires flexibility, mobility and modular construction.

The machine is suited to the excavation of various types of tunnels. It can cut access tunnels to underground orebodies, such as declines, portals, haulages, inclines, ramps, ring roads and connecting tunnels, besides others. Most of these tunnels are required during the development and preproduction stages of mine construction or mining. These tunnels are usually larger, with permanent services installed, and longer. As a result, the system uses a 5.5-m-diameter configuration, together with the bunker unit, to allow for seamless production, while trucks are switched to load and provide materials handling through inclines, turns and breakaways to the point of discharge, eliminating secondary materials handling.

The system’s smaller and shorter 4.5-m-diameter configuration is also used for reef drives and contact tunnels, which are frequently used in sublevel caving, block caving and steep- or shallow-dipping narrow-vein mining. The logistical and materials handling services allow for the fast relocation of the MTB machine to excavate tunnels in the production phase of mining.

“In mining, safety and efficiency are key. Knowing that these are continual concerns for our clients, we have developed this system with the potential to deliver exponential production rates, giving mine owners the ability to access underground orebodies faster, resulting in higher returns. It also allows for continuous operation and full-face cutting, with simultaneous rock support and materials handling,” explains Jordaan.

He adds that the system makes use of a predominantly nonexplosive continuous operation, where the crew is not exposed to an unsupported face or hanging roof, and little damage is done to the tunnel’s surrounding rock. The increased productivity, continuous operation, reduced manpower, proven consumable use and flexibility of use offset mechanised complexity for a cost-competitive alternative to existing mine tunnelling practices and access methodologies, stresses Jordaan

The tunnel offering is in the form of a contracted service where the mine owner is not required to invest in capital equipment.

“The company has interacted with industry throughout the development of this project and has ensured that improvements to the system will continue to be undertaken so that it ideally suits clients’ unique requirements,” states Jordaan.

TICKING THE RIGHT BOXES

While Master Drilling has undoubtedly become a respected global brand, Pretorius avers that the company can do more to increase its return on capital in 2019.

Master Drilling’s latest available financial results – for the interim 2018 period – show that the company saw its dollar revenue increase by 11.3%, while its dollar earnings per share decreased by 4.5% to 6.3c; its rand earnings per share decreased by 10.9% to 77.5c. Dollar headline earnings per share decreased by 10.6% to 5.9c and rand headline earnings per share decreased by 16.6% to 72.6c.

“Master Drilling performed adequately in 2018, but we are of the opinion we are not ticking all the boxes in terms of equipment utilisation and the quality of earnings,” says Pretorius. He explains that, by ensuring the projects undertaken by the company lead to optimal equipment use, the company should be able to improve its return on capital in the next financial year.

Pretorius states that the company would like to reach a return on capital of about 20% in 2019. He avers that, to achieve this goal, Master Drilling aims to bolster its order book with intensive boring projects in lucrative jurisdictions such as Canada, Australia and, more recently, West Africa.

“Master Drilling will be working hard at streamlining and optimising the projects it undertakes in 2019,” stresses Pretorius. He concludes that the company anticipates that its drive towards diversification and its goals to optimise project selection and productivity will bring better financial earnings in 2019.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation