New ore sorting tech launched at Indaba

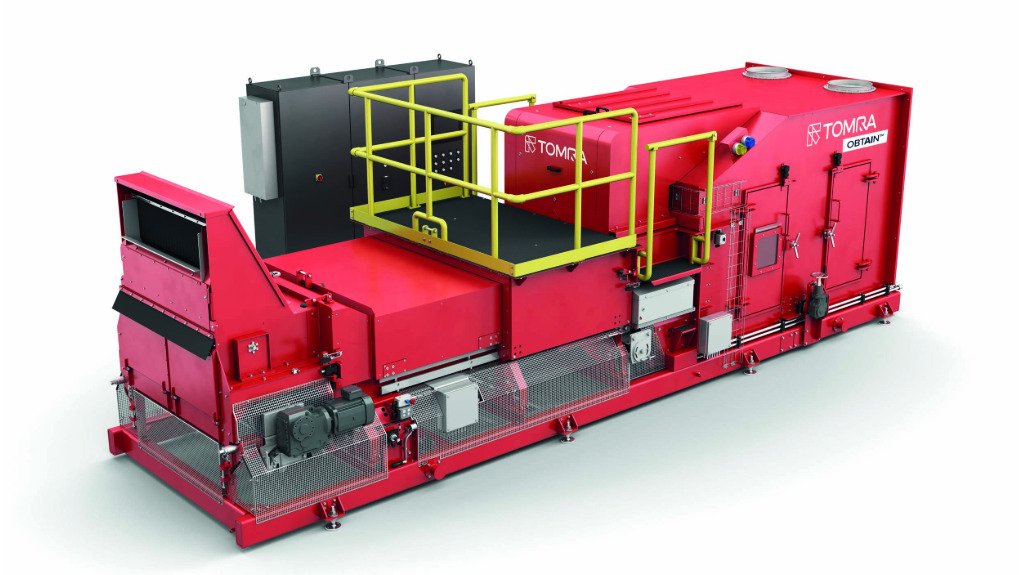

OBTAINING EXCELLENCE The new OBTAIN XRT sorting technology developed by Tomra Mining was showcased at this years Investing in Mining in Africa Indaba

TEAM TOMRA The team from Tomra Mining that represented the company at this years Investing in Mining in Africa Indaba

Collection and sorting systems developer Tomra Mining launched its Tomra deep learning solution OBTAIN, which is suitable for high-capacity ore sorting, at the Investing in African Mining Indaba, held in Cape Town, from February 5 to 8.

This newly developed software leverages deep learning to bring single-particle precision to high-throughput particle sorting, taking capacity, quality and recovery “to a new level” and unlocking value through a wealth of detailed and accurate data to enable better- informed decision-making.

“The Mining Indaba, one of the most important events in the mining industry, is the perfect platform for us to unveil our revolutionary OBTAIN,” says Tomra Mining head Albert du Preez.

He explains this is an "exciting innovation that marks the start of a new era in sensor- based sorting" and will enable mining operations to unlock untapped value and extend the life of mines.

Thus far, TOMRA has partnered with two customers to test the new OBTAIN solution in real working conditions.

The new OBTAIN software uses a neuronal network to identify the properties of each particle accurately and independently of the sorter’s capacity, achieving improved precision and reliability in detection and ejection.

Based on a client’s specific requirements, OBTAIN deployed at a mining operation provides the flexibility to either enhance the throughput of the sorter, while maintaining consistent sorting efficiency, or to improve sorting precision without compromising the existing throughput.

OBTAIN proves advantageous for a fully operational mine by enhancing recovery rates and elevating product quality within the existing throughput capacities of plant.

Conversely, in mines with additional plant capacity, it facilitates increased throughput without compromising product quality.

Further, this innovative technology has the capability to unlock untapped value from low-grade ore, waste dumps or materials previously deemed uneconomical for processing.

OBTAIN will also add value to a mining operation with its collection of detailed and accurate data, such as precise online particle- size distribution of the feed.

When used in combination with Tomra Insight, a cloud-based monitoring platform, it can provide the customer with detailed reporting on the performance of the sorter and its components to help them optimise the process, as well as enable them to plan for predictive maintenance.

The OBTAIN software has been developed for use with Tomra’s X-ray transmission (XRT) sorters.

OBTAIN will be available on new models of the XRT sorters, but there will also be an upgrade package available for existing machines, providing a significant opportunity for customers already operating Tomra XRT sorters to substantially enhance the sorting performance where it proves to be a suitable solution.

The software has been operating for close to 18 months at tungsten metal-based powders producer Wolfram Bergbau & Hütten’s tungsten mine in Mittersill, Austria, where it has delivered consistent and reliable performance.

The vicinity of the mine to Tomra’s development team has made it a good testing ground for the first phase, as Tomra has been able to monitor it closely.

A second phase of testing to quantify the improvements has been carried out with a trusted long-standing customer in a magnesite application, with results thus far indicating OBTAIN is ready to transform sensor-based XRT sorting in numerous applications.

Tomra offers demonstrations of its solutions with samples from their mine at the Tomra Test Centre in Wedel, Germany.

The Advent of AI

Despite artificial intelligence (AI) being popularised of late, with the uptake of technologies such as ChatGPT, the technology has been around for a long time, working quietly behind the scenes, says Du Preez.

The ability of computer systems to mimic human thought and decision-making to perform tasks that traditionally required human intelligence has played an important role in Tomra’s sensor-based sorting solutions for decades, automating the process and improving the accuracy and efficiency of the sorters, thereby unlocking value for mining operations, he states.

Tomra Mining’s experience with AI dates back to 1993, when its predecessor CommoDaS developed sensor-based sorters using AI in their image processing systems to identify particle properties.

“Over the years, sensor-based sorting technology has developed, and Tomra has been using machine learning in its XRT and near-infrared sorters for the last ten years,” concludes Du Preez.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation