Pharma contractor Wrapsa calls for more localisation as it celebrates four decades of operations

Wrapsa's ARV manufacturing facility

Photo by Creamer Media's Marleny Arnoldi

Container with ARVs

Photo by Creamer Media's Marleny Arnoldi

Effervescents manufactured by Wrapsa

Photo by Creamer Media's Marleny Arnoldi

Wrapsa's new gummy manufacturing machine

Photo by Creamer Media's Marleny Arnoldi

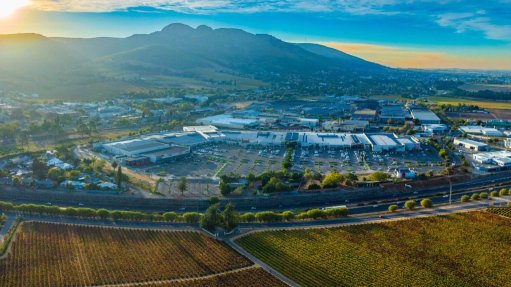

Wrapsa building in Pretoria

Photo by Creamer Media's Marleny Arnoldi

Wrapsa CEO Nardus Alberts

Photo by Creamer Media's Marleny Arnoldi

In celebrating its fortieth year of existence, pharmaceutical contract manufacturer Wrapsa has shared the difficulty pharmaceutical manufacturers have with high import duties for active ingredients and government tenders being awarded to foreign companies or government importing products rather than relying on domestic manufacturers.

During a media tour of Wrapsa’s facilities in Pretoria this week, CEO Nardus Alberts told Engineering News that, despite local capabilities to manufacture most kinds of pharmaceutical products, government often opted to award contracts to companies abroad or to import finished products, while also imposing a high import tariff on active ingredients used in pharmaceutical manufacturing.

He explained that it was cheaper to import finished products than raw materials, which hampered localisation and manufacturing potential in the country.

Nonetheless, Wrapsa has managed to grow from a 100 m2 facility in 1983 to a 25 000 m2 facility that produces pharmaceutical, cosmetic and food products on a contract basis, including antiretroviral (ARV) medication that helps manage human immunodeficiency virus.

Alberts noted that 50% of South Africa ARVs were produced locally, while the balance was imported from India. This is another statistic that could vastly improve with the right support from government, he said.

The company can cater to all medicine formats and packaging, be it tablets, syrups, ointments, powders, effervescents or gummies. It also provides laboratory services.

Responding to whether its facilities had undergone automation in recent years, Alberts explained that, owing to the flexibility needed with contractual manufacturing, automation did not lend itself well to sudden switches in manufacturing formats, hence the company’s use of 800 employees instead to ensure agile and flexible lines.

Wrapsa places emphasis on product traceability, with all raw materials getting unique identification numbers once these enter the receiving warehouse. Every sample is inspected and tested for quality, as raw materials often vary in quality.

The company manufactures products for about 80 different companies, more than half of which are based overseas.

For example, Wrapsa was recently awarded a contract to supply multivitamin gummies to a major Chinese company, for which it installed new machinery in a dedicated facility. The gummy manufacturing machine has been commissioned and will start delivering product in the coming weeks.

Another new addition to Wrapsa’s site is a lozenge and medicated lollipop facility, which is a highly temperature- and access-controlled space, like most of its facilities.

Wrapsa is Southern Africa’s largest independently owned pharmaceutical contract manufacturer and operates in line with the South African Health Products Regulatory Authority’s subscription to the Pharmaceutical Inspection Cooperative Scheme (PIC/S).

Wrapsa is also an ISO 9001:2015-accredited facility.

Ultimately, by adhering to the PIC/S guidelines, Wrapsa guarantees the quality, safety and efficacy of all medicines manufactured on site, with current Good Manufacturing Practice guidelines by the US Food and Drug Administration being the backbone of quality assurance in all areas of production.

When Wrapsa receives an order, it is processed by entering it into a production system.

This is a custom-designed Web-based program that is unique to Wrapsa and its needs as a contract manufacturing business. All departments have access to this system and can view the production schedule to set priorities. Planning then takes place based on what is scheduled and required for the period ahead.

This automated and exclusive operational system also provides Wrapsa with the much-needed platform to determine the availability of packaging components and raw materials.

It is also unique in that customers have remote access to their specific sections of the program, allowing them to track the progress of procurement and to determine when a product is due for production.

Alberts emphasised that local pharmaceutical manufacturing ultimately ensured lower costs for customers and quicker turnaround times, all while supporting jobs and skills development.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation