Satellite solution links mines to data benefits

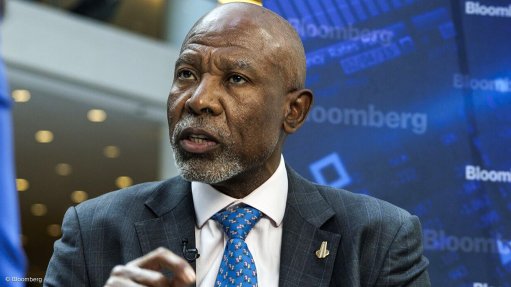

ADRIAN COMLEY Low latency performance and guaranteed bandwidth ensures that critical decisions can be made efficiently and reliably

Telecommunications company BT group’s medium earth-orbit (MEO) mining service provides a “game-changing satellite connectivity solution” for mining companies to improve performance, safety and profitability using the large quantities of data generated by their remote operations.

The MEO mining service was launched in 2020 in collaboration with satellite communications services providers Société Européenne des Satellites (SES) Networks and Talia. The service is high-capacity, robust and dedicated to individual clients, as well as built on uncontended throughput.

The combination of low latency performance and guaranteed bandwidth ensures that critical decisions can be made efficiently and reliably, says BT group managed network services senior manager Adrian Comley.

The service delivers high-performance 24-hour connectivity to support critical facilities, while connecting local employees to business applications and the wider world. It also enables and accelerates digital transformation towards an ultra-intelligent smart mine that bodes greater asset management, reduced infrastructure costs, improved safety, security, and efficiency and unrivalled quality of experience.

The MEO mining service is delivered through SES Networks’ O3b MEO constellation operating 8 000 km away from earth, and provides multiple offshore platforms with access to real-time monitoring and cloud-based applications comparable to that of an onshore platform using terrestrial networks.

“As mining companies are operating in increasingly remote locations under more challenging geological conditions, it’s necessary to deploy innovative equipment and techniques alongside proven, legacy operations,” explains Comley.

BT group has delivered a resilient infrastructure for a client – with sites in Nigeria, and in Basra, Iraq – by deploying satellite-based primary and backup connectivity networks.

In Nigeria, the solution delivered a high-throughput, low latency ethernet service. Certified to Metro Ethernet Forum (MEF) standards, the carrier class ethernet service guaranteed clients a fibre equivalent connectivity, providing large amounts of data in real time.

“This fibre-like connectivity continues to keep workers always connected, without interruption, and prioritises mission-critical data. It allows for operations to run smoothly and efficiently, both onshore and offshore, regardless of whether there’s fibre or communications instabilities in the local area,” says BT group global industries and government MD Eyad Shihabi.

He elaborates that reliable, accurate data that can be analysed in real time enables mines to respond to any situational challenges as they are occurring.

For example, the data of automated ground control systems used to detect ground vibrations can be analysed to determine which areas are safe for drilling and blasting, and which parts of the mine would be unstable or hazardous. The data can also be used to warn sites to withdraw mineworkers when a tunnel collapse is imminent.

Further, data on machines, their life spans, faults and other relevant data can be collated and analysed to predict machine failures before they occur to allow for preventative, rather than reactive, maintenance. Thus, mining operations can respond to safety hazards and avoid loss in production because of machine failure.

Transforming Industry Through Data

Mining companies face increasing demands from clients, investors and regulators to match supply achievements with even greater levels of environmental protection, safety and cost efficiency, Comley explains.

He elaborates that digital transformation can boost the mining industry through a variety of benefits that can lead to safer mining operations and increased profits.

The adoption of new smart technology is critical for the future of the industry and can help organisations to improve health and safety at work, as well as their environmental impact by saving lives, reducing and/or preventing injuries, lowering carbon emissions and waste, and increasing transparency and sustainability.

Fast, efficient and reliable data management can assist in automating some of the mining industry’s most challenging and dangerous tasks, such as self-driving vehicles, in impractical or hazardous environments.

Further, digitalised mining operations are able to take advantage of new capabilities such as large-scale digital twins of operations.

This allows for operations to be undertaken digitally first, which can assist mines in determining the best, most efficient way of achieving their goals virtually beforehand.

As more mining organisations move to smaller sites – which have historically been difficult or impossible to operate economically – operations require profitable management using agile handling of data from diverse sources.

Such operations need data to be processed and delivered to key people in near real time, typically through headquarters or data processing centres far from the mine.

Therefore, establishing fully connected mining operations using smart and automated technologies will enable them to access more reliable data over long distances to the often isolated mine locations.

Shihabi notes that limited coverage needs to be considered, particularly as MEO satellites currently cover a latitude band of only between 55ºS and 55ºN of the equator.

While a geostationary satellite can provide connectivity anywhere on earth, its associated latency issues are not ideal when connecting to a data centre or aiming for the real-time analytics of data.

However, low earth-orbit satellites offer extended coverage while new generations of MEO satellites are offering new inclined planes of orbit that will extend their coverage.

Shihabi concludes that the widespread use of MEO satellites ultimately depends on there being enough interest from clients for that technology to be made available.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation