Stimulating demand is most consequential action price-hit PGM industry can take

Fine platinum bars.

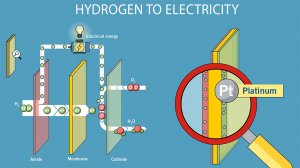

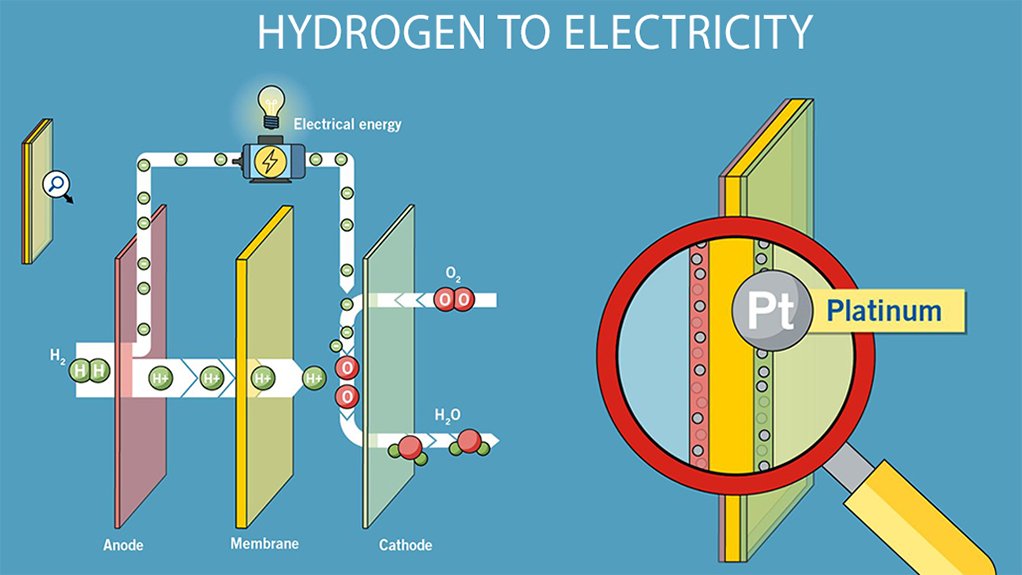

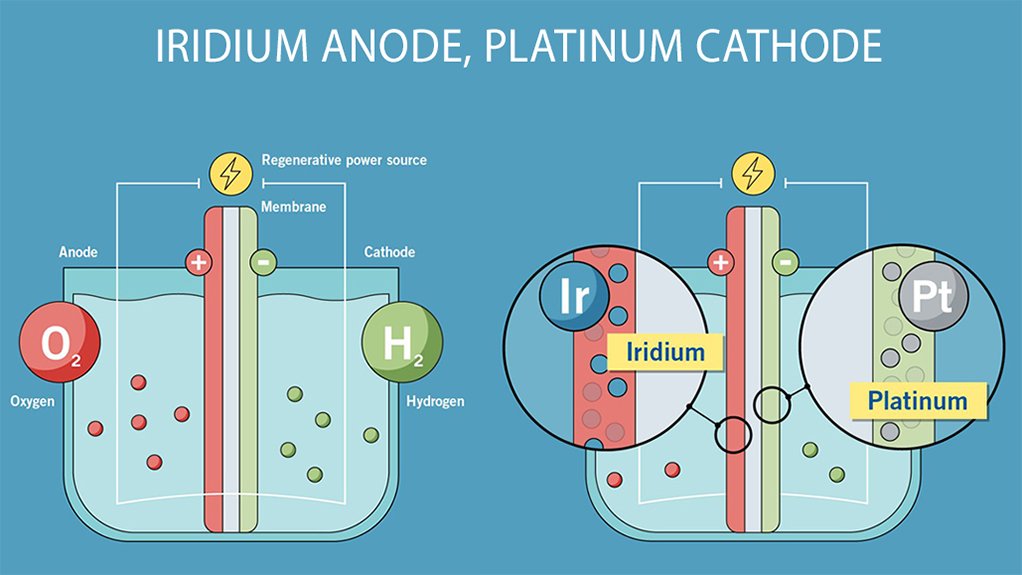

Platinum cathode needed in fuel cells to convert hydrogen to electricity.

Photo by Inforgraphic: Heraeus Precious Metals

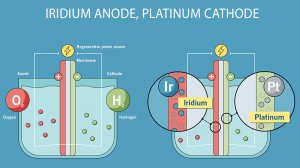

Anode of electrolyser iridium coated, cathode platinum coated.

Photo by Inforgraphic: Heraeus Precious Metals

JOHANNESBURG (miningweekly.com) – The most consequential action that price-hit platinum group metals (PGM) producers can take as an industry is the stimulation of demand.

“But the issue is, are we doing enough to advance the technologies that will benefit our industry, and our views always conclude that we should be doing more,” Implats CEO Nico Muller posits.

Currently PGM producers carry out demand stimulation through:

- Platinum Guild International (PGI), a marketing organisation created in 1975 with the vision to develop the global platinum jewellery market.

- AP Ventures, which advances innovation in hydrogen and decarbonisation.

- World Platinum Investment Council (WPIC), which provides insights to advance platinum investment.

- International Platinum Group Metals Association (IPA), which focuses on industrial demand issues.

- Shanghai Platinum Week, which this year served as a core platform for innovation and collaboration; and

- individual companies, for example Sibanye-Stillwater and Implats, have combined to sponsor switching technology between platinum and palladium.

“We also, from time to time, do research-type work in the industrial area, and specifically historically, we've worked very directly with the technical team of Heraeus in Germany to develop new applications,” Northam Platinum CEO Paul Dunne outlined during Northam’s media roundtable last Friday.

But while battery electrification has received major attention, “hydrogen has been the quiet brother in the corner”, Muller observed during last week's Implats' media roundtable.

“Most of us, not all, are members of collaborating entities. As Northam, we are members of the PGI, WPIC, and the IPA, and within those organisations we contribute financially, and with time, to promote use of these metals,” added Dunne in response to Mining Weekly.

Following the Shanghai Platinum Week, the Guangzhou Futures Exchange announced details of the first PGM derivatives in China, which are the country's first platinum and palladium futures contracts.

These physically settled platinum and palladium futures are expected to transform domestic price risk management and lift demand for platinum products.

"The reason we go to Shanghai is because China is the single biggest market and we need to be thoughtful and interactive there. We and Anglo American Platinum were well represented, and so was Tharisa Minerals.

"All three companies spoke during that conference on various aspects of mining and what we're all about and on the sidelines, professional contact was made and fiberglass, fuel cell and electrolyser producers visited.

"I do believe it's an important venue for the world's miners and we’ll continue to go, just like we go to the London Platinum Week," said Dunne.

On Northam also attending and presenting at the upcoming New York platinum event in the interests of demand stimulation, he added: "We’re going on an investor roadshow during that week to Boston and New York, specifically targeting our US investors post results, and we’ll also present at one or two of the platinum conferences that take place in New York."

COPING WITH WEAKER PRICING

The PGM industry is obliged to comply with very strict Competition Commission rules, which means that as producers, they must compete with one another. As single entities within this commodity market, they are not in a position where they can sit around a cigar table and agree in the way that the Organisation of the Petroleum Exporting Countries – OPEC – can, which is why Mining Weekly put this question to Muller: In what way is Implats strategising to cope with the weaker rand pricing for PGMs?

This was his response: “We always follow a very similar process. The best defensive strategy against weak pricing starts with maximising production throughput because we are a commodity producer, so an increase in volumes reduces one’s cost per ounce.

“The second strategy is to reduce costs – and you will see this from our year-on-year unit cost increase of 5% – but in part that is a consequence of incorporating Royal Bafokeng Platinum. If we exclude RBPlat, our costs were up by only 3%. We have seen in several of the operations, like in Canada, an actual reduction in unit operating cost, so there's a wide number of initiatives that we have included.

“You always start with the easiest elements, the discretionary spend. Further to that, the next step in the sequence would be to optimise capital expenditure.”

In 2020, Implats committed to a R50-billion capital investment programme, but because of the declining dollar and rand price basket, it has revised its plans and has curtailed capital in most operations apart from the strategic capital investment in Zimplats’ smelter expansion, and the solar plant.

It is guiding between R8-billion and R9-billion for the next year, which marks a significant decline in capital.

In addition to that, there has been labour restructuring at most of Implats operations, and the step after that is a change of operating strategy, to the extent that one can leverage any improvement, such as at Impala Canada, where no cost saving or capital deferment or any normal restructuring would have sufficed, and where higher margin ounces have been targeted.

But what if prices decline even further?

“If prices had to decline even further, as a last resort, all companies exposed to these markets would have to consider portfolio optimisation,” said Muller.

“We have made a statement that we will not support loss-making operations, and to the extent that it is improbable that we can bring an operation back into a positive, or at least a neutral cash position, that will be the next step in the company thinking.

“At this point, I just want to be clear that it has not been necessary for us to get to that level, and the extent to which the company may consider those steps will depend on our operational performance, combined with market evolution going forward."

Another element needing sensitivity is the extent to which new ounces coming onto the market are promoted: "As an example, we have the Merensky expansion project at Two Rivers that has been suspended, and we think that that is going to assist market balance.

“So, industry discipline with regards to bringing new ounces on board is critical, and Implats, given its dominance as a player in the market, has a role to play in that regard,” Muller outlined.

PHYSICAL MARKET AND PRICE DISLOCATION

What is being experienced is a dislocation between the physical market and the price, with a factor differing from supply-and-demand dynamics being observed.

“We've got a strange phenomenon now where we have good buying from our customers, every ounce that we produce is called for, and yet we see these low prices, when we've got metals in deficit and projected to be in deficit for some time. So, we are dealing with a different factor than just pure supply/demand dynamics here," Implats group executive corporate relations Johan Theron pointed out.

“The other thing to factor in is that we've just come off an upcycle with record pricing. During that up cycle, no additional capacity was added by the industry, and a year into lower prices has seen a curtailing of capital, a pulling back of projects. Even our own Two Rivers’ Merensky project has been put on care-and-maintenance.

“Not only has the industry not added additional capacity in the upcycle, but I think you're going to see over the next five years that from this point on, the production output will stabilise and come down slightly.

“But if you look at what we're going to be producing with the next five, ten years, versus what we produced 20 years ago as an industry, for instance, the world has changed,” Theron explained.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation