The lube kitchen part 5: demystifying demulsifier additives

This article has been supplied.

By: Steven Lumley - technical manager, WearCheck

(Virtual Showroom)The next chapter in the ongoing narrative around additives, with WearCheck - the specialist condition monitoring company - centres around demulsifiers.

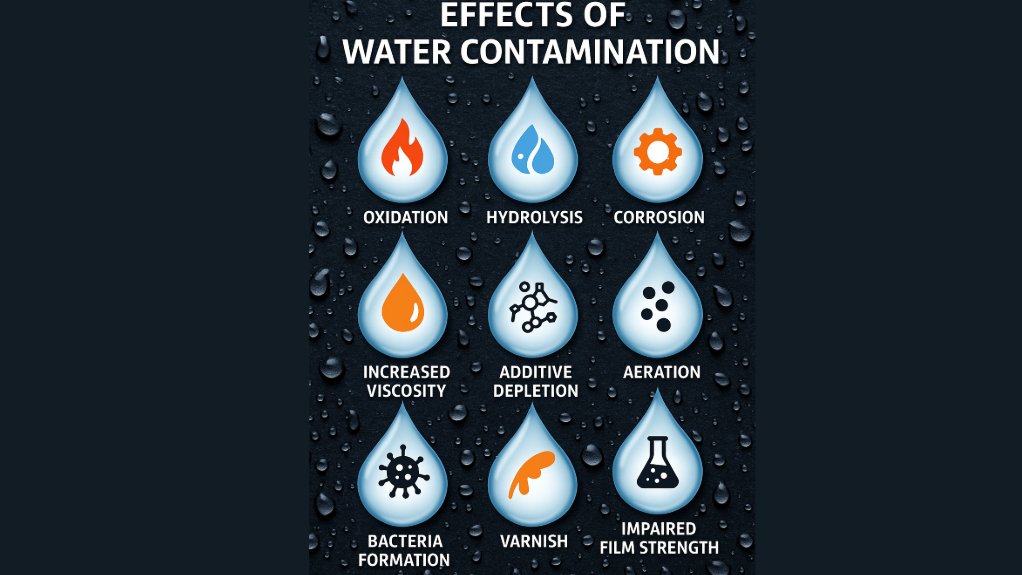

The effects of water on oil and the system being lubricated are insidious. Water is one of the most destructive contaminants in almost all lubricants and applications. It attacks the base oil, the additives blended into the oil, and the mechanical system being lubricated.

Water can hasten the oxidation of a lubricant and ultimately shorten its service life. It encourages the build-up of sludge and varnish, and causes metal parts to rust and corrode.

But wait, there’s more! Water can also deplete the lubricant’s film strength, making components more vulnerable to wear, while stripping the lubricant’s additives, which impacts its performance and diminishes its ability to protect metal surfaces.

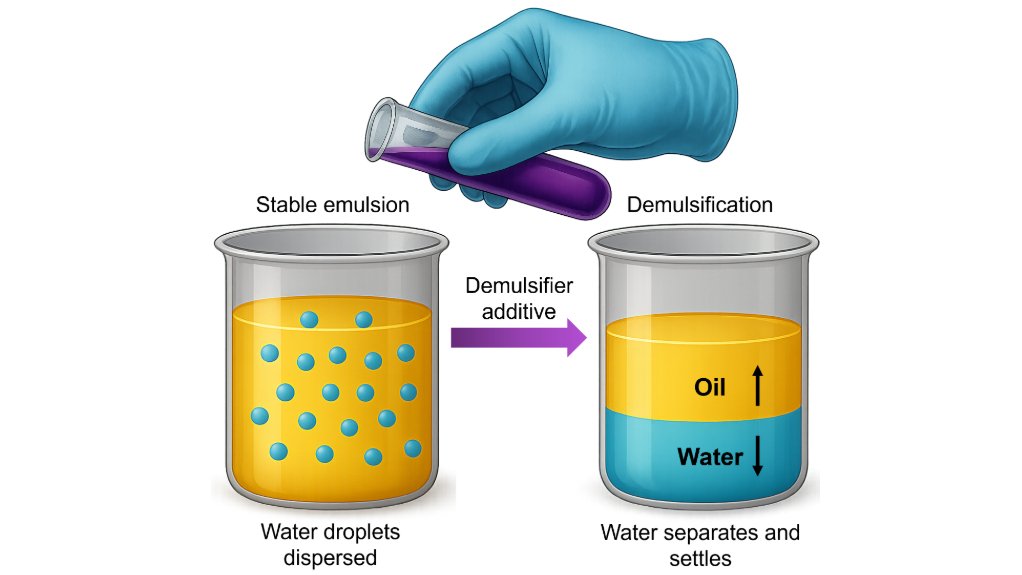

Many oils separate well enough from water on their own, but some base oils and additives are prone to forming a stable emulsion when water is present, and, as such, require the addition of a demulsifier additive.

Demulsifier additives prevent the formation of a stable oil-water mixture or an emulsion by changing the interfacial tension of the oil, so that water will coalesce and separate more readily from the oil.

This is an important characteristic for lubricants exposed to steam or water, so that free water can settle out and be drained off easily at a reservoir. Most engine, gear, hydraulic and turbine lubricants are formulated with this additive.

Just to be clear, demulsifer additives don’t stop the ingress of water into the oil but instead allow the water to separate out more readily, and in so doing, limit its destructive potential.

An interesting fact about this lesser-known additive - the chemical compounds used to create demulsifier additives are actually the same group of chemicals used to form stable oil-water emulsions in oil-water-based metal-working fluids and fire-resistant fluids, but in much lower quantities. That’s right folks, the same stuff that demulsifies can also emulsify if large enough quantities are added.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation