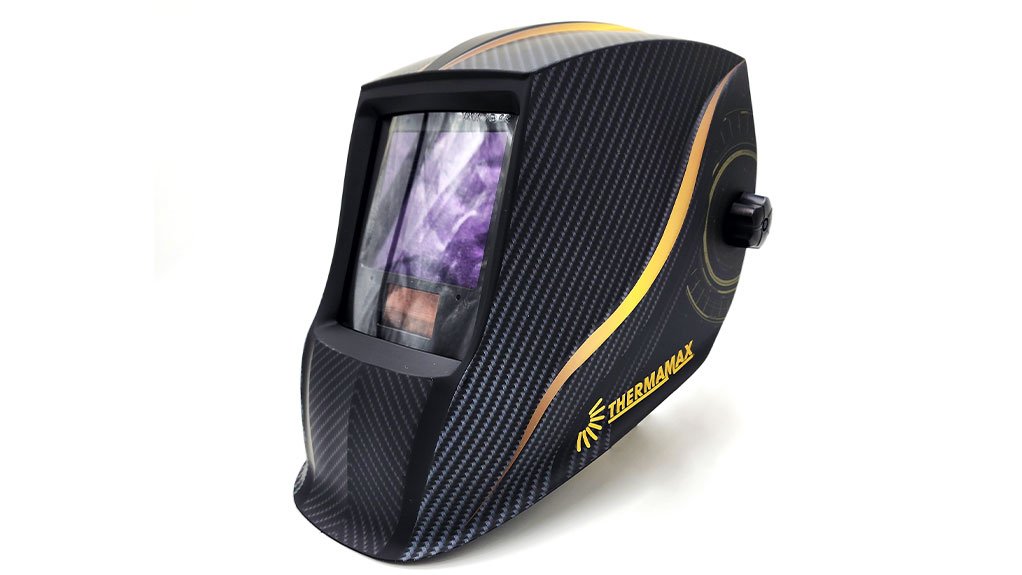

Thermamax TITAN adjustable solar helmet

The welder is widely regarded as the premier athlete within the realm of metal craftsmen, bearing a significant level of responsibility, as a defective welding seam could potentially lead to catastrophic and even fatal accidents in extreme circumstances. Investing in a high-quality welding helmet ensures that every weld is done with precision and care, while also safeguarding the welder’s well-being. A high-quality welding helmet increases efficiency, accuracy and overall comfort. From protecting against harmful rays to providing clear visibility, a top-notch welding helmet is a non-negotiable necessity.

What sets the Thermamax TITAN range apart is that it offers users the ability to choose between two Auto Darkening Filters (ADF), either the Diamond ADF or the Onyx ADF, providing flexibility and customisation based on individual preferences, whether it is prioritising clarity or versatility. This level of customisation ensures that users can optimise their experience based on their unique requirements.

The Diamond ADF is designed to offer exceptional clarity and visibility, ensuring that users always have a clear view of their work. On the other hand, the Onyx ADF is known for its reliability and versatility, catering to a wide range of welding applications.

The new Tru-Vision Colour Technology built into the Titan Diamond ADF revolutionises the welding experience by providing welders with unparalleled clarity and visibility. With an astounding light transmission in bright conditions, welders can now work with a practically unclouded and clear view of their working environment, offering insights into a new dimension.

This level of clarity allows welders to see the joining process as it actually takes place, from the melting of the weld pool to the creation of the weld seam. The almost perfect colour spectrum of the Diamond ADF enables welders to have complete control over their work, with the ability to see how the filler material is immersed in the welding pool.

Superior visibility before and during welding is essential for ensuring safety at work. By having a clear view of the work area, welders can better anticipate potential hazards and take the necessary precautions to avoid accidents. Additionally, superior visibility allows for more precise and accurate welding, resulting in higher quality workmanship and, ultimately, creating a safer and more productive work environment.

The sensitivity adjustment feature ensures that the right protection level is always maintained, offering brilliant vision and clarity, as if looking through a window pane. In light mode, the colour perception is akin to looking through clear window glass, while in dark mode, welders can enjoy a detailed and high-contrast view of the welding pool with unprecedented clarity. With a protection level of 2.0 in its light state, the TITAN Diamond ADF allows welders to see their working environment as if they were not wearing an auto-darkening lens at all.

The TITAN Onyx ADF utilises an adaptive shade level sensitivity adjustment, which automatically sets the optimal shade level between 5 to 13. This feature ensures that you are always protected while welding, as it continuously adjusts to the appropriate shade level based on the intensity of the welding arc.

With the inclusion of an additional brightness sensor, any changes in arc intensity are immediately detected and the shade level is adjusted accordingly. This means that manual adjustment is no longer necessary, providing a seamless and hassle-free welding experience. This advanced technology guarantees that you remain perfectly protected at all times, regardless of the specific welding parameters being used.

Sensitivity Adjustment Control

The sensitivity adjustment control found in both ADFs automatically sets the right protection level within a range of 4 to 12, ensuring that you are always perfectly protected. This is made possible by an additional brightness sensor that measures the intensity of the welding arc. With this feature, you no longer need to make manual adjustments, as the ADFs will take care of setting the appropriate protection level for you. This adaptive control system simplifies the welding process, allowing you to focus on the task at hand without having to constantly monitor and adjust the protection level. Overall, the ADFs provide a reliable and convenient solution for ensuring welding safety and protection.

Comfort

The Thermamax TITAN helmet range prioritises comfort above all else, making it one of the most comfortable welding helmets available. Its superior dual-strap adjustable comfort headgear with torque ratchet and comfort band ensures a secure and personalised fit for each user. Additionally, the included Speedy Loop hard hat adaptor enables the wearer to attach a hard hat to the helmet, allowing for simultaneous use of both items.

Despite its advanced features, this helmet remains lightweight, reducing strain on the wearer during extended use. Further, it offers a convenient grind mode, eliminating the need to switch between helmets for different tasks. To provide added peace of mind, the Thermamax TITAN helmet comes with a 12- month warranty, ensuring long-term satisfaction and protection for the user. With its focus on comfort, versatility and durability, this helmet is a top choice for welders seeking a reliable and user-friendly protective solution.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation