TROTECH reaffirms its reputation as BTT’s tank builder of choice

To build BTT’s 18 new bulk-storage tanks, TROTECH deployed its innovative reverse building method

The contract for BTT entailed jacking 18 tanks in a week; installing 1225t in steel in 10 months; and undertaking 852X-ray welds

Acting on behalf of a provider of unique hydrocarbon solutions, TROTECH successfully converted a molasses tank into a heavy-fuel oil tank by replacing its wooden roof with a new steel cone roof with rafters

TROTECH completed its work for the provider of unique hydrocarbon solutions ahead of schedule

This article has been supplied.

Bidvest Tank Terminals (BTT), South Africa’s foremost independent bulk liquid and gas storage operator in South Africa, continues to leverage TROTECH’s formidable bulk tank design, procurement and construction services to successfully complete its large capital expansion projects.

Working alongside the Owner’s Engineer, TROTECH recently completed the construction of 18 new bulk-storage tanks at BTT’s state-of-the-art tank farm in Richards Bay, KwaZulu-Natal. TROTECH has since been appointed to construct two additional 15 000m3 storage tanks for this leading steward and handler.

Notably, this was the first time that TROTECH was tasked with building 18 bulk storage tanks simultaneously – a task that the company took in its stride. Achieving this impressive feat again showcases TROTECH’s commitment to always meeting client’s expectations and finding the best way to do so. Certainly, “Around here, You can count on Me and Around here, We find the Best way” are unwritten ground rules that emanate throughout M&D Group.

This is exactly the mindset that Storme Wilson, TROTECH’s Senior Project Manager, and members of his skilled and experienced team, which peaked at 300 employees, maintained throughout the project duration. They commenced site erection in August 2023 and successfully completed the project at the end of May 2024.

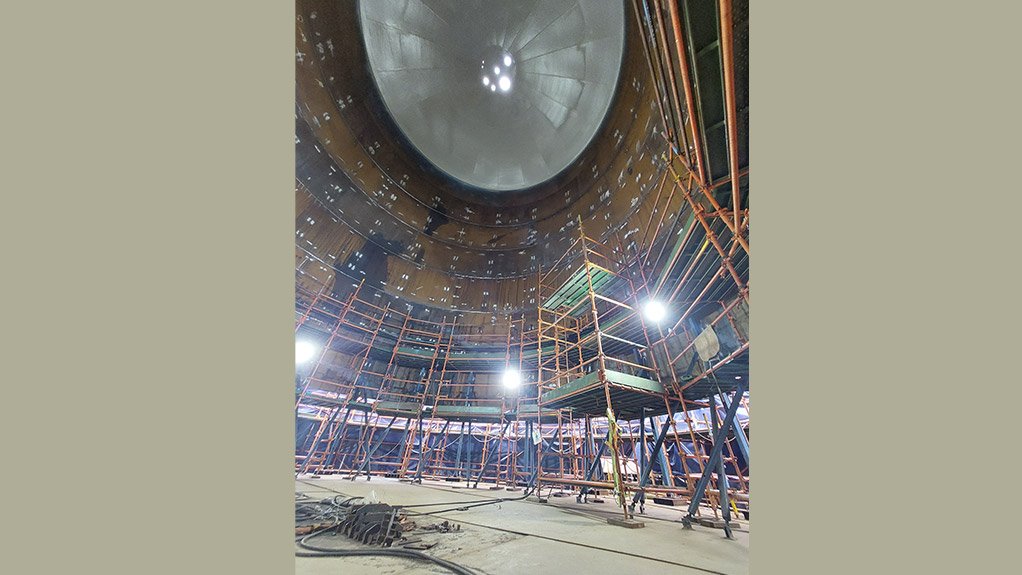

The project entailed the design, supply, delivery and erection of 15 self-supporting dome roof structures, each 14 500mm in diameter and 19 000m in height, and three 18 000mm diameter and 14 000m high cone roof structures. Included in the scope of work was the supply and installation of shell and roof nozzles; manholes; peripheral roof handrails; spiral staircases; and inter-tank bridges.

Once again, TROTECH deployed its innovative reverse building method for tank construction. This technique entails constructing tanks at ground level and progressively jacking them one strake at a time to their final height after undergoing rigorous quality inspection and control. The method offers enhanced safety, precision and speed in tank construction, reducing the need for working at heights and minimising the amount of internal and external scaffolding required.

“We jacked 18 tanks in a week; installed 1 225t of steel in 10 months using four tower cranes; and undertook 852 X-ray welds, of which less than 1% required rework. This while working in an extremely congested site with multiple interface activities. Innovation has always been at the heart of M&D Group. ‘Around here, We find the Best way’, another M&D Group unwritten ground rule that translates words into action,” Wilson says.

In line with M&D Group’s focus on Khula Nathi: “Around here, we grow, you succeed”, 10 members of the Richards Bay community received training. Outstandingly, 80% of all labour was sourced from Richards Bay.

TROTECH Operations Director, Gavin Heron and Managing Director, Lukas Brink, lauds the performance of the TROTECH team on this project.

“Based on the high quality of our workmanship, we have nurtured a more than 20-year professional relationship with BTT. Certainly, we will again strive to deliver the same high standard of workmanship that this valued client has become accustomed to from us when constructing the two additional tanks,” Heron says.”

TROTECH has also nurtured long-term working relationships with other clients, including leading hydrocarbon producers.

The company’s recent stellar performance on the Tank Roof Replacement project at Durban Harbour enabled TROTECH to secure additional work for another important client, a provider of unique hydrocarbon solutions.

This project entailed removing the wooden roof of a molasses tank and replacing it with a new steel cone roof with rafters enabling it to now store heavy-fuel oil (HFO). Notably, the project was completed ahead of schedule, with TROTECH commencing site erection in February 2024 and finalising the work scope in the beginning of July 2024. There was also not a single health and safety incident on site, demonstrating the company’s commitment to another important M&D Group unwritten ground rule: “Around here, Safety begins with Me.”

The new contract will entail building six additional tanks as part of the second phase of the expansion of this worldclass tank farm in KwaZulu-Natal.

“Reputations are built over many years. TROTECH has more than 30 years of proven track record under the belt. Over three decades, we have built more than 240 tanks, providing more than 1,1 million m3 of storage capacity, in 11 different countries. With each build, we have become even better at what we do, earning us an enviable reputation as the tank builder of choice,” Rukesh Raghubir, Group Chief-Executive Officer of M&D Group, concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation