Vesconite Bearings powers new machine with solar energy

This article has been supplied.

Vesconite Bearings is excited to announce that most parts produced on its new 450-ton injection-moulding machine have been proudly labelled "Manufactured with Solar Power” following the machine’s commissioning in June 2024.

The introduction of the cutting-edge machine was preceded by an integrated energy management project that significantly bolstered the company’s renewable energy capacity. Key installations included 1,080 solar panels, each rated at 600W, generating a total of 648 kW; seven inverters rated at 100 kW each, providing 700 kW of power; eight batteries with a capacity of 225 kWh each, contributing a total of 1.8 MW of stored energy; a software monitoring system to optimise energy use; and two mini substations rated at 500 kVA each.

As a result of Vesconite Bearings’ investment in renewable energy, the injection moulding machine is powered by Vesconite Bearings’ solar energy system supported by its battery energy storage system. Not only does the moulding machine operate on renewable energy, but its energy-efficient design also means it consumes 54% of the energy of a hydraulic injection-moulding machine, allowing more of Vesconite Bearings’ operations to be driven by solar energy.

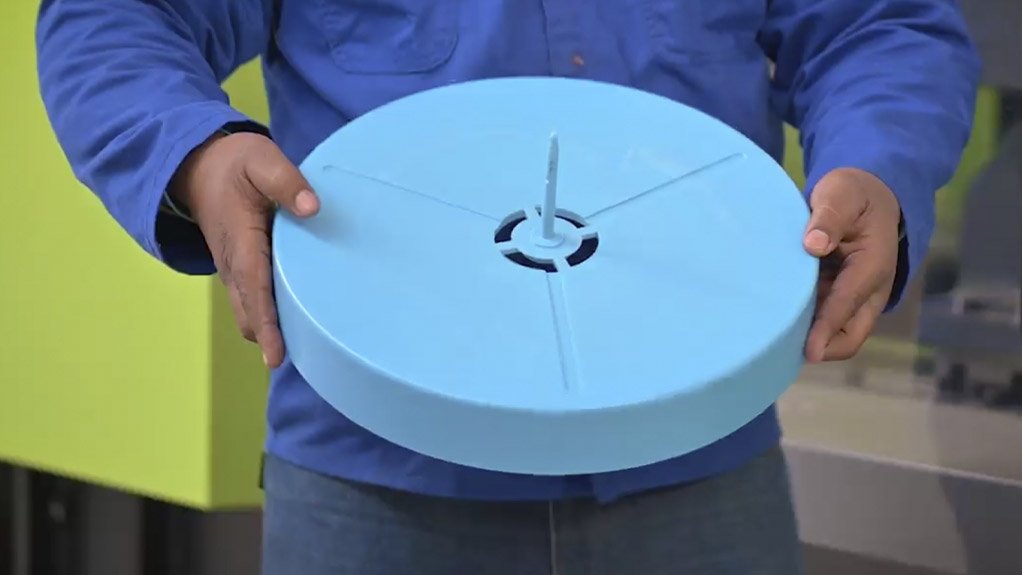

Christian Brumloop, Vesconite Bearings' Moulding Department Division Head, emphasises the machine’s production capabilities, noting, "Our new moulding machine features a shot weight of 4.5 kg and a pattern opening stroke of 1.3 m. These specifications are crucial for us because they enable the production of larger parts with greater accuracy.”

The machine has already proven itself in its first few months of operation, producing over 3,000 parts, and delivering exceptional quality. Tests conducted in Vesconite Bearings' laboratory have confirmed the high quality of the parts.

Brumloop expresses his enthusiasm for the new addition to the production line, saying, "The new machine that we have received this year is just amazing. It not only allows us to produce larger quantities and sizes of parts but does so with outstanding precision and quality.”

Vesconite Bearings remains committed to integrating sustainable technologies into its production processes and reducing the environmental impact of its operations. The addition of the new moulding machine, powered by solar and battery energy, marks a significant step forward in the company’s green manufacturing journey.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation