VW Africa expands solar array at Kariega plant to more than 12 000 panels

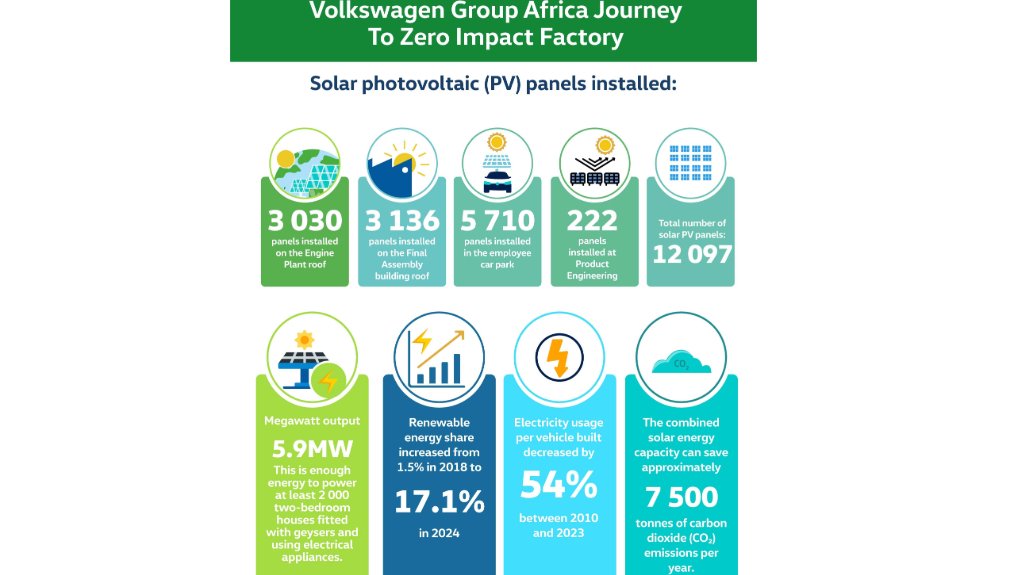

Volkswagen Group Africa (VWA) has added an additional 3 MW solar power to its local grid, bringing the total output of renewable energy to 5.9 MW.

This is enough energy to power at least 2 000 two-bedroom houses with geysers and electrical appliances.

The total number of solar PV panels across the company now stands at 12 097, of which 5 710 panels were most recently installed in the employee car park.

The first phase of the solar project started two years ago, with 3 030 panels placed on the engine plant roof, and 3 136 panels on the final assembly building roof.

More PV panels are on the way as the project roll-out is set to continue.

VWA says it has invested close to R100-million in solar energy to date.

The current combined solar energy capacity can save about 7 500 t CO₂ emissions a year.

The share of renewable energy at the vehicle manufacturer has increased from 1.5% in 2018, to 17.1% in 2023, which significantly reduces its reliance on electricity supplied by the local authority.

VWA production director Ulrich Schwabe says the company is projected to see a 23% drop in fossil fuel dependence by 2025.

This highlights the Kariega plant’s goal to be a zero-impact factory by 2030.

“Our efforts to reduce carbon emissions are in line with Volkswagen Group’s global Go To Zero Environmental Strategy, aimed at achieving carbon neutrality, which is aligned with the Paris Agreement,” says Schwabe.

“As a result, all Volkswagen Group plants are highly focused on decarbonisation, with renewable energy playing a key role in this effort.”

Schwabe adds that the electricity-use per vehicle manufactured at Kariega decreased by 54% between 2010 and 2023.

These savings were achieved through various initiatives, such as a demand-side management plan.

“We are consistently monitoring processes and influencing mindsets towards energy consumption, such as air-conditioner usage,” he notes.

Since 2010, Kariega’s environmental impact has improved by 57.7%, which includes cuts in energy consumption, water, waste, solvents and carbon emissions.

VWA produces the Polo and Polo Vivo for local and export markets.

The Kariega plant has been battling unreliable electricity supply from the Nelson Mandela Bay municipality.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation