Water treatment solution reduces complexities at mine

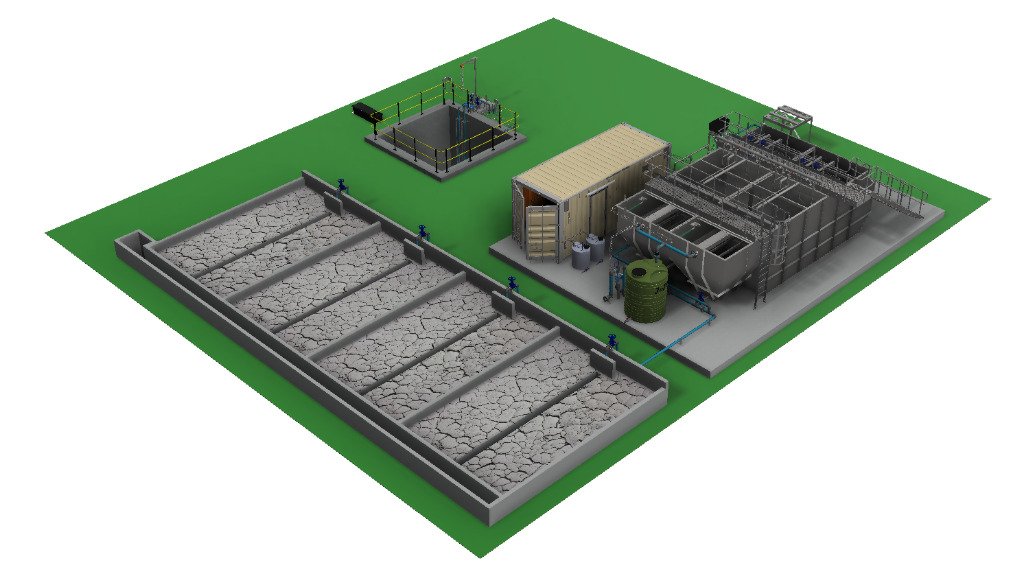

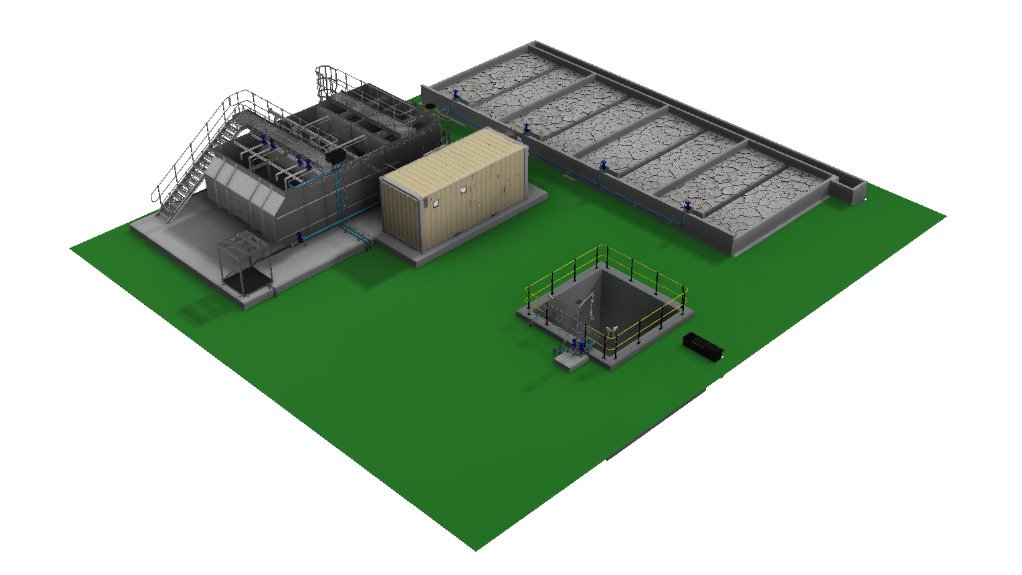

SIMPLIFYING LOGISTICS The plant is designed and constructed to fit within the footprint of standard shipping containers, ensuring safe delivery of the complete plant

ANTICIPATED INCREASE The water treatment plant forms part of the mine's anticipated pit expansion project which will see an increase in personnel

Wastewater solutions contractor WEC Water recently completed a wastewater reticulation and water treatment plant for a gold mine in Burkina Faso, significantly reducing the mine’s reliance on external sewage removal and enabling the reuse of treated water.

WEC Water was appointed by the mine to conduct an audit of the existing wastewater handling facilities at the mine in February 2023. The audit formed part of the mine’s preparations for a planned pit expansion, resulting in an expected increase in the number of personnel in the area.

At the time, the mine used tanker trucks to remove sewage from seven collection points, including the camps and other operational locations.

However, this method presented various challenges, including increased operating expenditure owing to rising diesel costs, undesirable traffic entering the mine area and a loss of reusable water in dry regions. Additionally, the method posed the risk of sewage storage facilities overflowing, resulting in malodours and disease vector attraction, reports WEC Water.

In response to these challenges, WEC Water aimed to find a long-term solution to treat the sewage at the mine and reclaim water for use as dust suppression and irrigation activities, as well as to reduce demand on potable and rainwater reserves for these purposes.

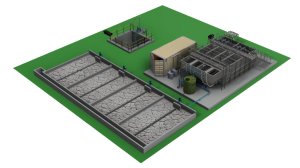

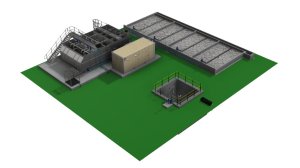

WEC Water proposed a solution comprising three core elements, namely a new collection and pumping system, a centralised biological treatment plant and a treated-water storage lagoon.

The pumping system directs sewage to a centralised wastewater treatment plant, which biologically treats between 60 m3 and 100 m3 of wastewater a day, reducing chemical oxygen demand and nitrogen levels. The treated water is then stored in a lagoon for reuse.

A major challenge of this project arose owing to the mine’s remote location, says WEC Water senior contracts and project manager Nigel Birchall, explaining that this required considerable logistical expertise to ensure the safe delivery of the complete plant to site without damage.

“The packaged design of the plant simplified the process as most of the plant was built within the footprint of standard shipping containers,” he says.

Several WEC Water personnel – including process, mechanical and commissioning engineers – were onsite during the construction and commissioning phases of the project to ensure that the plant was successfully installed and commissioned, as well as to provide oversight during the installation phase.

The project, according to the company, builds on its comprehensive experience with water and wastewater treatment in West Africa.

Design Specifications

The sewage treatment plant was designed by WEC Water’s specialist process and mechanical engineers team to meet the required discharge standards using a modified Ludzack-Ettinger treatment process.

As a result, the plant uses an activated sludge system with nitrogen-reducing capacity.

During the treatment process, the wastewater is pumped through an upfront screening box and then enters a concrete buffer tank, which is designed to contain peaks and avoid overloading of the biological reactor.

The bioreactor, designed by WEC Water, is comprised of two zones – the anoxic and aerobic zones – and includes an integrated clarifier.

The screened wastewater is pumped into the anoxic zone of the reactor, where a submersible mixer maintains constant mixing of the anoxic mixed liquor.

An air-lift pump then transfers mixed liquor to the aerobic zone, which induces the A-recycle for nitrogen removal.

Air diffusers, fed by blowers, drive air into the reactor to maintain the biological oxidation and continuous mixing effect.

Sludge recirculation retains healthy sludge in the system while periodic wasting to drying beds ensures a consistent sludge retention within the reactor.

Additionally, aluminium sulphate is dosed during the process to enable compliance with local phosphate limits.

Disinfection is achieved by dosing a hypochlorite solution into the clarifier overflow before entering the chlorine contact tank, following which the treated effluent is stored in a lagoon for subsequent reuse as dust suppression, irrigation water or for safe environmental discharge.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation