Africa’s dewatering champion: Integrated Pump Technology tops global Grindex rankings

Integrated Pump Technology’s strategic growth and commitment to service excellence have made Grindex pumps a preferred choice for demanding dewatering applications across Africa

Integrated Pump Technology’s longstanding partnership with Grindex has set new global benchmarks, earning recognition as the largest Grindex distributor in the world

With a deep understanding of African mining challenges, Integrated Pump Technology delivers Grindex submersible pumps engineered for maximum reliability in the toughest conditions

From deep-level mines to remote open pits, Integrated Pump Technology and Grindex provide fit-for-purpose dewatering solutions backed by responsive technical support

The trusted combination of Integrated Pump Technology’s expertise and Grindex’s world class submersible pump design is keeping water challenges under control across Africa’s mining sector

This article has been supplied.

Integrated Pump Technology has reached a remarkable milestone - being recognised as the largest Grindex distributor in the world - a testament to its strategic growth, technical expertise and customer-centric approach across Africa’s dewatering sector.

Founded in 2014 to fill a clear gap in the market, Integrated Pump Technology set out with a focused vision - to deliver high quality fit-for-purpose dewatering solutions backed by local expertise and responsive after-sales support.

“From day one, our focus has been on solving real problems for mining and industrial customers dealing with water ingress, whether that is surface dewatering, underground operations or challenging slurry environments,” Jordan Marsh, Managing Director of Integrated Pump Technology, says.

A cornerstone of the company’s early strategy was its partnership with Grindex, a globally respected Swedish manufacturer of electric submersible pumps. “We have been committed to the Grindex brand for more than a decade and our team knows these pumps inside out,” Marsh adds. “What set us apart from the beginning was our service philosophy - we didn’t just sell pumps; we backed them up with technical support, spares availability and rapid response.”

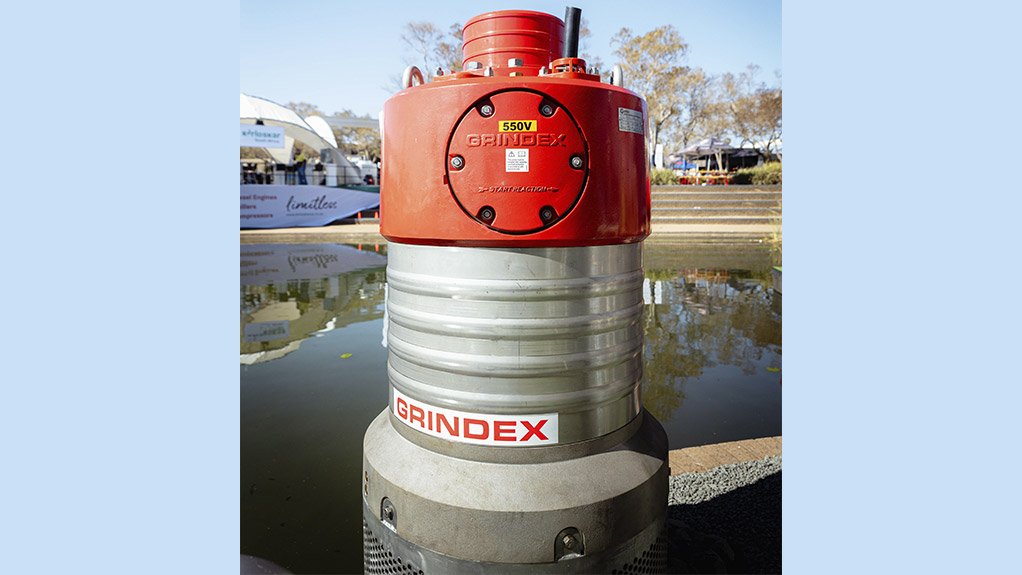

Grindex pumps are engineered for demanding environments. Their cast aluminium construction ensures a lightweight but rugged design, while the use of wear-resistant materials - such as nitrile rubber impellers and stainless-steel components - makes them ideal for abrasive conditions. Their patented SMART motor protection system guards against voltage fluctuations, phase failure, overheating and overload, allowing for greater reliability and reduced maintenance costs.

Strategic Growth Across Africa

Integrated Pump Technology’s footprint has expanded significantly across the continent, in what Marsh describes as a deliberate and carefully planned journey.

“Many of the challenges our South African customers are facing - like harsh operating conditions and the need for reliable performance - are even more pronounced in other parts of Africa,” he explains. “Remote sites, extreme terrain and limited technical support on the ground made it essential for us to build a robust support structure as we expanded.”

The company’s success has been built on deep engagement with local markets and understanding customer needs on the ground. This includes tailoring solutions to suit varying environmental factors - such as silt-heavy water, high temperatures, high static heads and logistical difficulties in transporting and servicing equipment. Grindex’s plug-and-play design, coupled with features like the air valve system for dry running, has proven particularly effective in mines where pumps are frequently exposed to variable water levels.

Today, Integrated Pump Technology boasts a strong presence in countries such as Zambia, the Democratic Republic of Congo (DRC), Tanzania and more recently across West Africa, where it has been officially appointed the Grindex distributor.

A major milestone in this regional expansion has been the establishment of a bonded warehouse in Ghana, enabling faster delivery of both Grindex submersible and Godwin diesel-driven pumps and spares to customers across West Africa. “Having local stockholding is a gamechanger,” Marsh notes. “It means we can respond faster, reduce downtime for our customers and ensure ongoing support even in the most remote areas.”

Commenting on the company’s expansion across Southern and Central Africa, Marsh emphasises the importance of operational readiness. “It is all very well to have product available to sell but if you don’t have the right support and infrastructure in place, you won’t succeed. That is why we have formalised distributor relationships, invested in in-country stockholding and put systems in place to improve responsiveness. We also invest heavily in technical training for both our internal teams and our partners, ensuring our pumps are always supported by solid application knowledge.”

The Grindex and Godwin Advantage

At the heart of the company’s offering are two globally recognised pump brands - Grindex and Godwin. This dual offering allows Integrated Pump Technology to meet a broad range of dewatering challenges from power-restricted remote sites to high head high volume pumping in demanding mining conditions.

Grindex submersible pumps are renowned for their robust construction, low maintenance design and exceptional solids handling capabilities. Available in dewatering, sludge and slurry configurations, these pumps operate efficiently in extreme underground environments.

The Grindex Mega, for example, is capable of flows up to 150 litres per second and heads exceeding 150 metres, making it suitable for deep level mining applications. The Grindex Bravo series, on the other hand, is ideal for heavy duty slurry applications, featuring a built-in agitator and wear resistant materials to handle high concentrations of solids.

“These pumps are engineered to meet very specific demands, and we work closely with each customer to ensure the right pump is specified for the right job,” Marsh says.

On the diesel-driven front, the Godwin range - including popular models like the HL150 and HL160 - caters to operations where grid power is unavailable or unreliable. These automatic self-priming pumps are ideal for high head applications such as open pit dewatering. The HL150, for instance, can handle heads of up to 140 metres and flow rates up to 150 litres per second, making it ideal for mines requiring deep sump drainage or long distance pumping. The rugged construction and option of trailer-mount or skid-mount make Godwin pumps easy to deploy across tough and remote terrain.

“Having both electric submersibles and diesel-driven pump sets allows us to meet customer needs irrespective of the application or energy source,” Marsh says. “Flexibility is key when you are operating in Africa.”

Recognition and Outlook

Being named the largest Grindex distributor in the world marks a significant achievement - not only in terms of sales volume, but also in the trust and credibility the company has built in the field.

“This is not a one-man job,” Marsh says. “It is the result of consistent performance, market knowledge and customer focus from the entire Integrated Pump Technology team. It is also a reflection of the trust our customers place in us.”

Marsh says that Integrated Pump Technology’s ambitions remain firmly rooted in Africa. “Our aim is to entrench our leadership position by building deeper partnerships, expanding our footprint and raising the bar for dewatering support. As mining operations become more complex, water management will only grow in importance, and we are ready to meet that challenge head-on. We are not just a pump supplier. We are a technical partner,” Marsh concludes.

With a proven track record, market-leading brands and a growing support network across the continent, Integrated Pump Technology is set to lead the way in delivering reliable fit-for-purpose dewatering solutions - no matter how tough the conditions.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation