App allows remote predictive maintenance of gearless mill drive systems

A new application from ABB allows for remote monitoring of gearless mill drive performance

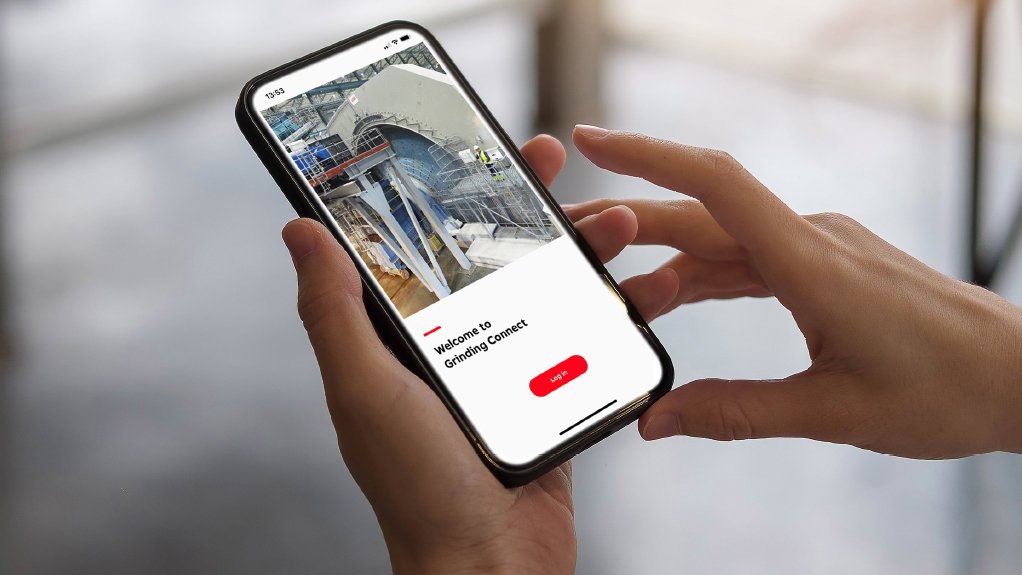

A new application (app) allows mine operators to check gearless mill drive (GMD) performance from anywhere by means of a smartphone or tablet.

Global technology company ABB has updated its ABB Ability predictive maintenance for grinding, moving it to a cloud-based platform that includes the Grinding Connect mobile app that allows real-time notifications on fleet status.

The company notes that its solution provides easy access to GMD system parameters and allows visualisation of performance considering past activity and real-time data and assesses future maintenance requirements. It aims to extend the lifetime of grinding assets through better use of resources and to support non-stop operation and to avoid unforeseen downtime.

The new ABB Ability predictive maintenance facilitates greater data gathering by increasing the data sample per mine and offering more reliably defined analytics and trends. The solution features a new user experience with fully customisable dashboards, alarms and events all available on the mobile app.

GMDs are recognised as the preferred grinding solution at mines characterised by higher-capacity production coupled with low ore grades. By eliminating bolt-on mechanical components such as ring-gears, pinions, couplings and gearboxes, GMDs offer ore producers unrivalled availability, efficiency and durability, while reducing operational expenditure.

“A GMD is a major investment and its availability is essential for the process,” said ABB global product manager: grinding service in mining Angeles Fernandez. “Unscheduled shutdowns and system failures can lead to significant losses in production.”

“ABB Ability Predictive Maintenance for grinding is a state-of-the-art service for analysing system data, assessing the current condition of the equipment and applying predictive methods. The new version is unique in the market and the new Grinding Connect app means you can check that your GMD is performing through your phone or tablet - it is as familiar as the many personal apps we use for monitoring our health, catching up with the news, or checking on the home or children.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation