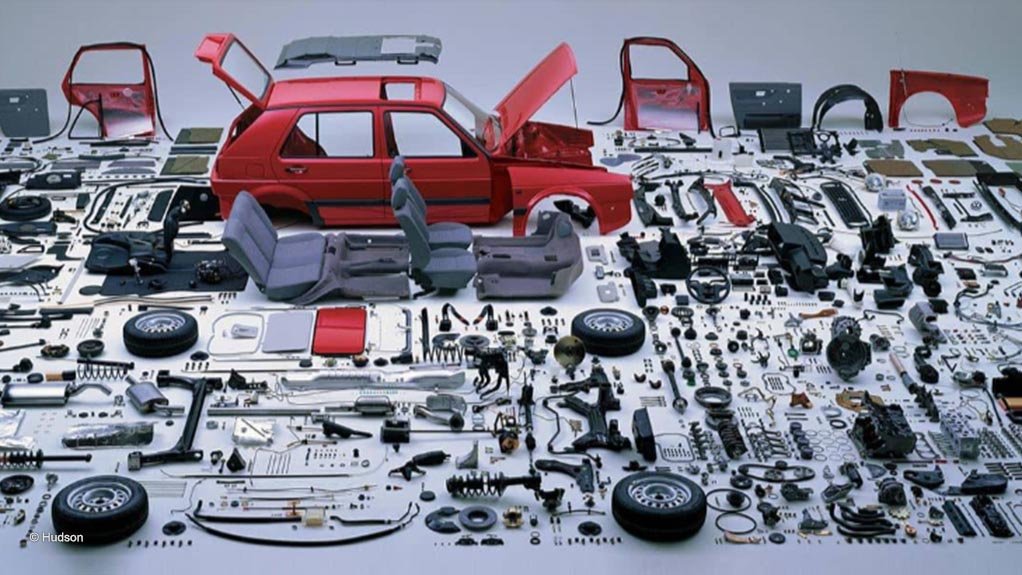

Auto sector should consider increased import substitution – Hudson Rubber

Import substitution in the local automotive industry is crucial for the growth of the South African economy, says Hudson Rubber Company MD Stoney Steenkamp.

Hudson Rubber is a Hammanskraal-based rubber and plastics manufacturer which has been in operation for 64 years.

Steenkamp says while the perception regarding the quality of locally produced automotive components is changing for the better, more needs to be done, and at a much faster pace.

“Local substitution saw a significant increase during Covid due to the disruption of overseas distribution channels, forcing local companies to source components at home.

“Since then, when speaking to a number of auto component manufacturers, import substitution has grown.”

Going forward, however, the process of substituting imported parts for made-in-South Africa parts requires South Africa-based companies to display the will to find local suppliers.

“Although government is participating in the initiative, it is not up to them alone to force the change – automotive and related companies also need to make localisation a reality,” says Steenkamp.

“Businesses are generally aware that purchasing locally means shorter lead times, better cash flow, less administration, and none of the complications experienced with importing.

“However, it seems businesses would rather invest in negotiating with foreign suppliers on issues such as improved terms, lower costs and more reliable shipping methods, than invest the same time and effort with local manufacturers.

“In the cases where some local companies do not react to support local customers, their actions are most likely justified, however, this cannot be generalised,” notes Steenkamp.

He adds that localisation can also benefit buyers by allowing them the opportunity to customise or make changes to products in a relative short space of time, adapting to country-specific requirements.

Import substitution can also increase innovation, which, in turn, generates better engineers, which is a boon to the domestic economy.

Steenkamp refers to the vision of the National Tourism Sector Strategy, which is to “rapidly and inclusively grow a tourism economy that leverages South Africa’s competitive edge in nature, culture and heritage, underpinned by Ubuntu and supported by innovation and service excellence”.

“Why can’t we extend this strategy to the automotive and other industrial sectors?”

Steenkamp cites the local public transport sector as one example where import substitution can make a positive impact.

“The vehicles that are locally build should contain locally sourced products that are competitive and on par with imported quality.

“Why are imported parts still used in locally-build vehicles that are used to transport millions of our workers each day – especially when local suppliers are competitive in their costs, provide short lead times, offer cash flow benefits and create much needed local jobs?”

Steenkamp says there must be urgent and strong emphasis on companies to commit to at least consider import substitution.

“In the rubber and plastics industry, for example, Hudson has the expertise and machinery to provide a variety of solutions to the local original equipment manufacturer (OEM, or vehicle manufacturer) market.

“However, as with a number of other industries, OEMs are either not under pressure to buy local products, or they are restricted by their overseas principals to only source from their global supplier network.”

“Willing local suppliers have a lot to offer,” emphasises Steenkamp.

“They want purposeful and committed engagement from OEMs that will make localisation a reality, for the barriers to be removed and to build local capacity. OEMs do have capacity and the capability to make this a reality.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation