Controlling several flow rates simultaneously with the new Festo Motion Terminal app

This article has been supplied.

The Festo Motion Terminal VTEM combines digitalisation and pneumatics. Quickly activated Motion Apps are revolutionising pneumatics by increasing flexibility, energy efficiency and accelerating production processes. Thanks to the new Motion App “Flow control”, the VTEM now makes filling containers such as bottles with nitrogen or other gases more profitable and economical.

Digitised pneumatics marks the start of a new age of automation technology. Motion Apps control one piezo valve for almost all pneumatic tasks. Only one piece of hardware is needed for this: the Festo Motion Terminal. The different functions are controlled using Motion Apps. Festo is gradually developing new Motion Apps that are making the Festo Motion Terminal more and more flexible. This reduces complexity and time to market. Digitised pneumatics intelligently connects the mechanical system, electronics and software - ensuring better overall equipment effectiveness (OEE) with lower energy consumption.

Digitised flow control

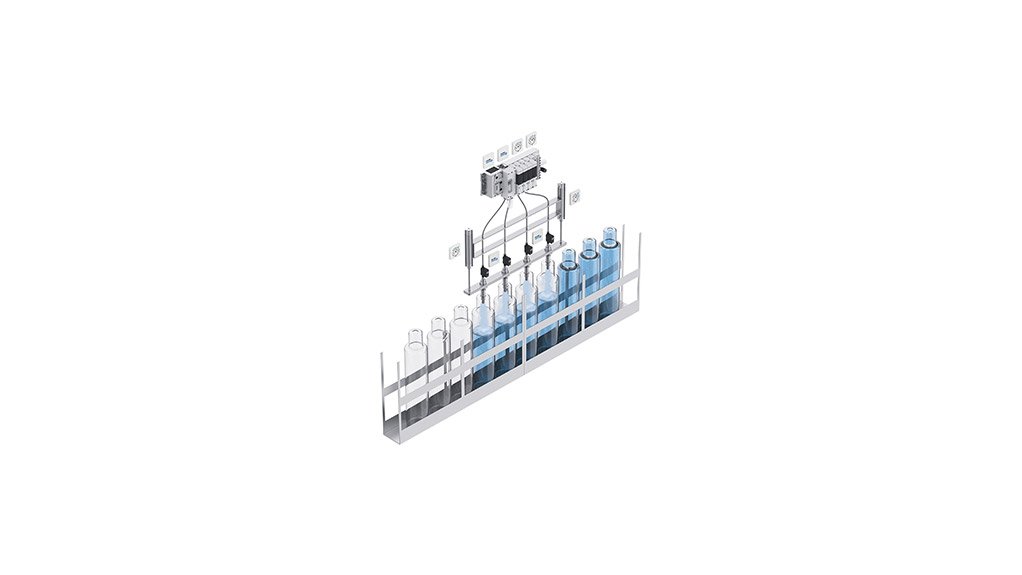

An application example: containers for products are often rinsed and filled with gases like nitrogen. With the Motion App “Flow control”, users control compressed air and gases flow rate at up to 600 l/min digitally and simultaneously on up to eight independent channels. For precise dosing, the integrated sensors can be combined with external flow sensors. This saves energy and costly gases.

Controlling the flow in litres per minute using the app allows the gas to be precisely dosed. The more precisely the filling quantity is defined, the more accurate the filling will be since the percentage deviation from the target quantity can be optimally detected. This flexible, digitised nitrogen control is tamper-proof.

In addition, the app “Selectable pressure level” moves the filling nozzles to the bottles quickly and accurately, and the flexible parameterisation shortens the cycle times. After filling, the filling nozzles are retracted with reduced pressure to save energy.

Software instead of hardware

Thanks to the fast activation of new functions via Motion Apps, machine developers can create a basic machine type using the Festo Motion Terminal and then select the relevant Motion Apps to equip it with different functions and features as per the customer’s requirements. The ability to copy and transfer parameter sets makes planning easier and saves time. Assigning functions via software has the added benefit of preventing tampering and protecting know-how since it is not possible to tell from the outside which functions the valves are executing.

By additionally using the Motion App “Leakage diagnostics” in the application, maintenance is simplified as it automatically monitors for leaks. Malfunctions can thus be detected and pinpointed to a specific actuator using diagnostic cycles and defined threshold values – the reliable basis for predictive maintenance.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation