Drive systems delivery in process

DRIVING GROWTH The SEW-EURODRIVE drive systems will be used on a new electro-coating facility at an automotive manufacturer in Mexico

Drive component manufacturer SEW-EURODRIVE’s Gqeberha branch, in the Eastern Cape, is in the process of delivering drive systems that form part of a major project to an automotive machine builder, also in Gqeberha.

These drive systems are part of an order the machine builder is supplying to its client – an automotive manufacturer in Mexico – which entails fit-for-purpose drive systems for the electro-coating facility of the manufacturer.

The drive systems will, once commissioned, transport vehicle chassis stacks through a series of pretreatment and electro-coating processes, where the vehicle chassis are primed, coated and then cured in an oven.

“The first system is being installed and tested, and will be commissioned soon,” says SEW-EURODRIVE Gqeberha mechatronics engineer Francois Sieberhagen.

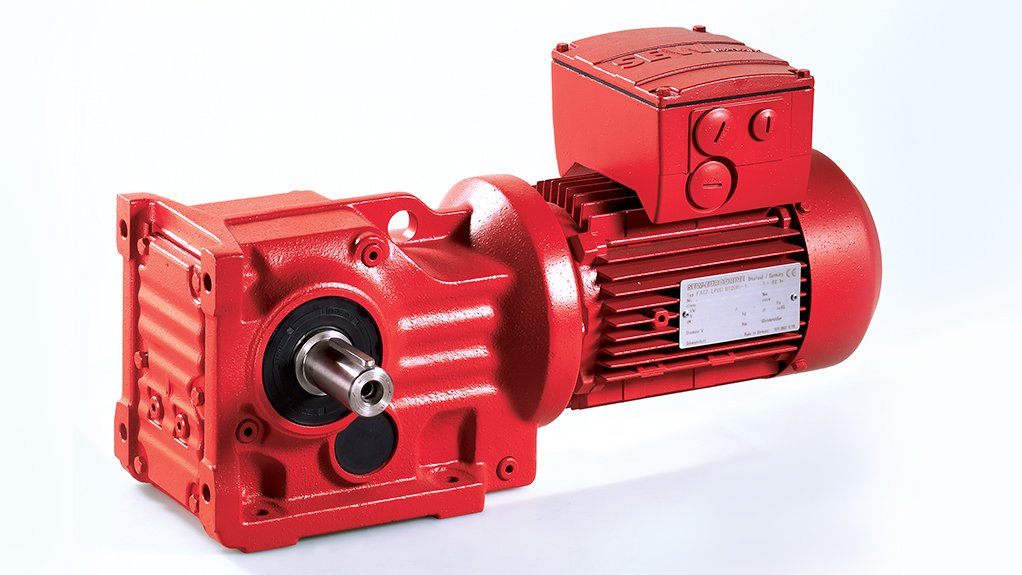

He adds that each system consists of a complete solution comprising motion controllers, frequency inverters, fieldbus interfaces and geared motors, all of which are manufactured by SEW-EURODRIVE.

The order entails the supply of 63 geared motors, ranging from 0.37 kW to 22 kW, which will be used in the various stages of the electro-coating and curing processes.

The drive system will control applications such as hoisting, travel drives, tilting drives, side shuttles and conveyors, as well as pitch and role capabilities.

Every system was individually sized and selected to meet the specific load and speed demands of every application, and to adhere to the cycle-time requirements of the automotive machine builder’s system.

“We have imported the parts for the drive systems from our principal in Bruchsal, Germany, which we are assembling and delivering to our client in batches,” Sieberhagen adds.

The order was secured in the last quarter of 2021, and delivery will be complete before the end of the year.

He enthuses that, owing to the company’s strategic positioning in Gqeberha, it is well equipped to cater to the automotive sector, which is prominent in the Eastern Cape.

“We have managed to hone our skills and design capabilities to suit the automotive sector, which constitutes a substantial market share for this branch in particular.”

Sieberhagen adds that the experience needed to correctly calculate, design, size and supply the fit-for-purpose drives components for the client stems from previous business in the sector, and from this client in particular.

“We have supplied many similar successful projects to our client, and this adds to the history of success for both parties.”

Sieberhagen concludes that SEW-EURODRIVE is a global market leader in the field of drive technology solutions, and is often the supplier of choice.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation