Dwyka Mining Services proudly represents incredible bulk handling with LASE Industrielle’s TVM-3D-M

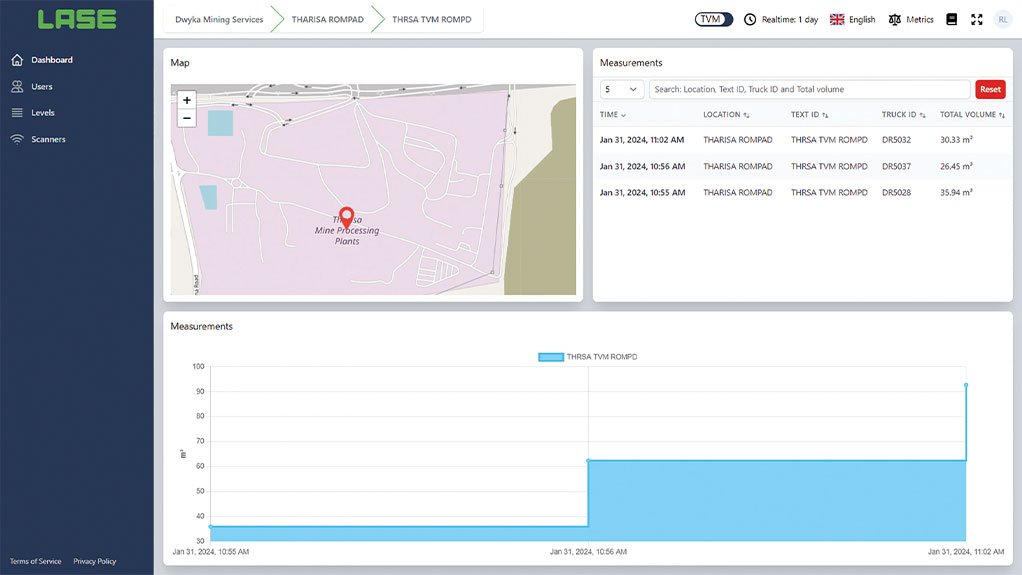

Real-Time Visualisation: LASE Cloud allows for remote monitoring to assess volumetric flow across platforms and user-base with connection to the Internet

LASE TVM-3D-M: LASE Truck Volume Measurement utilises two 3D scanners to capture profiles of empty and filled mining trucks to calculate the net volume

The Problem

Traditional load and haul analysis methods have been characterised by estimations and disjointed data, resulting in delayed decision-making and suboptimal load optimisation. The maintenance-intensive nature and high calibration costs of weighbridges and load cells further compound these challenges, leading to inaccuracies in load measurements.

The Solution

By leveraging industrial laser measurement LASE’s truck volumetric scanning solution, TVM-3D-M, a cutting-edge 3D laser-based scanning technology, PGMs and chrome miner Tharisa Minerals, situated on South Africa’s western limb of the Bushveld Complex, implemented a reliable and contactless in-motion scanning system.

This innovation enabled the mine to accurately measure truck volumetrics in real-time, facilitating the establishment and enforcement of consistent loading profiles. Consequently, Tharisa reduced hauling time, minimised fuel costs and mitigated maintenance and downtime expenses.

Objectives Achieved

Through the deployment of LASE’s advanced scanning technology, Tharisa Minerals successfully optimised its fleet’s capacity without increasing trips, thereby enhancing operational efficiency and maximising profitability amid fluctuating input costs.

BIG 5

- Delivering more volume with the same number of trips

- Increased fleet capacity to focus on waste mining

- Savings in diesel usage

- Savings in maintenance costs

- Overall cost per cubic delivered savings

Implementation Process

- Implementation Timeline: The scanner was installed in Q2 2023 and operationalised in Q3 2023 following calibration, custom interface development and testing.

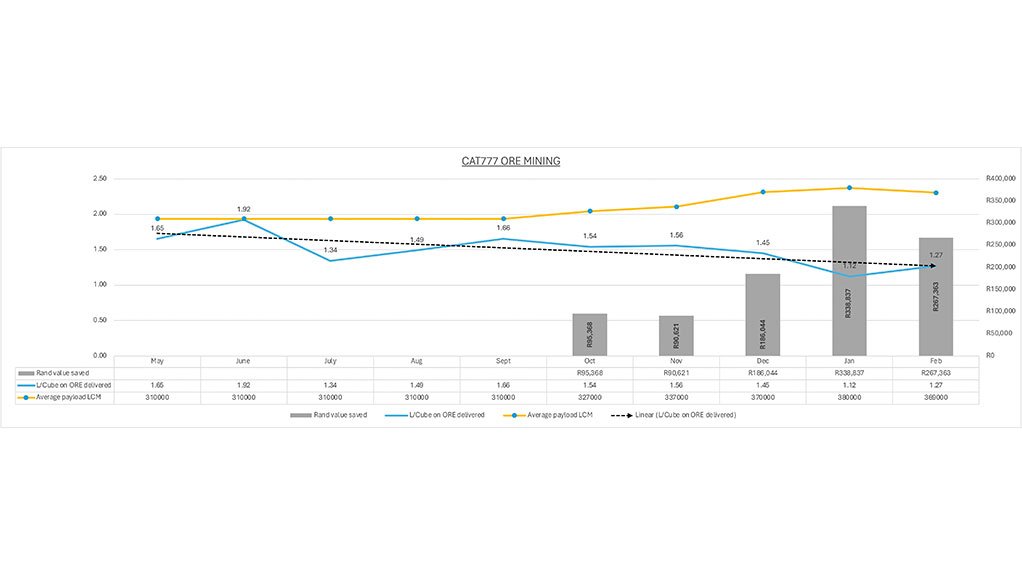

- Baseline Development: Approximately 2 000 scans were conducted between September and October to establish performance baselines for the CAT777 fleet.

- Target Setting: Leveraging original equipment manufacturer specifications, a phase-one target of 35 loose cubic meters (LCMs) was set, representing a 16% increase from the baseline, equivalent to around 11 additional tonnes per load for CAT777 fleet trials.

- Scope Expansion: Initially trialed on the CAT777 fleet, representing 70% of ore mining, the system integration is now being extended to include the CAT785 fleet, with similar benefits anticipated by mid 2024.

Return on Investment

- Reduction in diesel use: Significant reductions in fuel consumption were observed, with a notable decrease in fuel usage per cube delivered, resulting in substantial diesel savings.

- Optionality for strategic decision making: Reliable and accurate load profile data elevated production profile and empowered decision making to assess revenue and cost saving initiatives to suit operational requirements.

“The consistent achievement of the 35 LCM target post-implementation has been instrumental in guiding strategic decisions and exploring avenues for cost savings and revenue enhancement. The initiative holds the potential to significantly impact organisational profitability and operational optimization” – Johan (JC) Du Preez Digital & Automation Manager

KEY TAKEAWAYS

Option 1:

Park 3+ Trucks

- Cost Saving

R3 234 306.71

(Potential Annual Cost Saving)

Option 2:

Run Increased Tonnes

- Revenue Enhancement

Additional Tonnes to ROM:

±149 520 t

“Initially, our target was 35 LCMs which we comfortably met. We’ve since raised the target to 37 LCMs for the CAT777 fleet. Additionally, we’re now monitoring the CAT785 fleet, which has already shown an 8% increase (with another 5% to 10% potential), and we’ve also begun monitoring the Volvo fleet operated by our mining contractors. Greater visibility across our bulk material movement empowers our team to make informed decisions on the fly” – Alwyn Jooste Mining Optimisation Manager

*Disclaimer: Revenue increase is subject to the assumption that increased waste leads to augmented ore tonnes.

Visit:

Discover the product video and more innovative solutions from LASE.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation