Effective training with welding simulator

WELDING PRECISION Theory must be accompanied by practical training to improve understanding

Educational solutions supplier Sangari South Africa reports that the Soldamatic simulator, which it uses to assist in the training of apprentices, has won top honours at this year’s Worlddidac Awards, held in Berne, Switzerland, last month, for the most innovative educational product of 2014.

The Worlddidac Award is presented by the Worlddidac Foundation as an internationally recognised distinction for educational resources. Participating companies are chosen for their ability to offer innovative educational products and solutions for all levels of education. The award was first bestowed in 1984 and it is presented biennially.

Sangari South Africa CEO Bez Sangari tells Engineering News that the company introduced the welding simulator to the local welding training industry in 2011, as Sangari identified a need for training theory to be complemented by practical exercises to ensure that trainees understand what they are being taught.

He adds that the company imports the simulator from Spain, where it is manufactured by Seabery Soluciones. The product is sold for between R180 000 and R300 000, depending on the product options selected by the buyer. In addition, clients also have the option to rent the welding simulator.

Since the introduction of the simulator, Sangari has seen companies achieve training cost savings of at least 40%. “The simulator requires no costly welding consumables, such as covered electrodes, cored wires, strips and fluxes, and it reduces training time by half,” he explains.

Sangari adds that the Soldamatic simulator is also ecofriendly as it does not produce any gas emissions. “It is a safe environment, with no need for special clothing or ventilation. The welding can be done in any classroom. It is 100% safe, simply because it is a virtual welding environment,” he explains.

“The system creates an augmented-reality three-dimension vision in a workshop environment. A large training institution can realise a return on investment in eight months to two years. The quick return on investment is achieved as no materials are used and there is no wastage,” he continues.

Although the uptake for the simulator has been slow, the company expects it to improve, as more companies and training institutions become aware of the product. To date, it has been mostly used in the further education and training college sector, and at artisan training centres, says Sangari.

How It Works

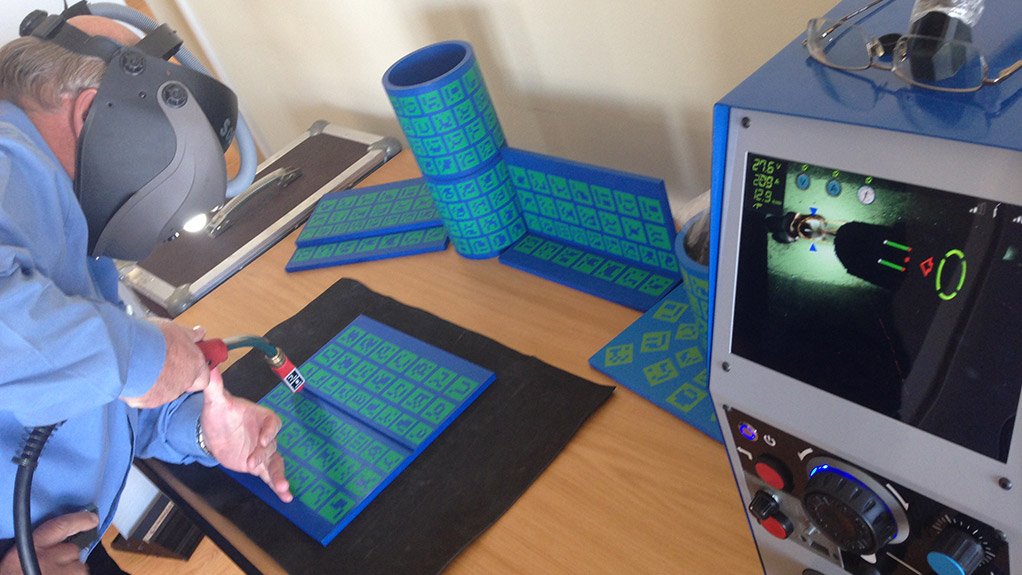

The simulator consists of a hardware unit the size of a standard personal computer, with a built-in screen that not only enables the trainer to view the student’s progress in real time but also records the training.

The trainee also wears virtual-reality headgear to simulate a real welding environment. The headgear generates realistic welding graphics, such as the weld pool and beam, and emits simulated smoke and sparks. The headgear also simulates heating, cracks, filler material, gravity and undercutting.

“Welding skills can be taught for specific applications and the trainees’ performance can be measured in a fair, reliable and unbiased manner. The unit includes 93 different training lessons, but more customised lessons can also be added,” explains Sangari.

He says trainer and trainee can analyse and assess the latter’s welding performance in a video format and evaluate skills such as welding velocity and stick-out, as well as travel and working angles. When required, maintenance and upgrades of the simulator software can be done remotely.

“The system supports arc welding processes of shielded metal, gas tungsten and gas metal; a variety of welding joints, such as V-butt joints, lap joints, T-joints, pipe-to-square butt joints and pipe T-joints; and a variety of angle-welding exercises,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation