Electrotron elevates utility’s conveyor safety through strategic innovations

With a specialisation in longer conveyors, original-equipment manufacturer (OEM) Electrotron has established itself as a key partner to State-owned power utility Eskom over the years, particularly through its involvement in major projects such as the Medupi and Kusile power stations.

This partnership has allowed Electrotron to demonstrate its capabilities, aligning its strategic goals with those of Eskom, and ensuring a long-term relationship built on trust, reliability and innovation.

The relationship began in 2010, when Electrotron undertook the Medupi project through a partnership with industrial equipment solutions ELB Group (then known as EL Bateman), which served as the main contractor on site.

Electrotron’s role in the project entailed the supply and installation of conveyor belt safety systems – which included emergency pull switches with integrated pre-start warning sirens, conveyor belt speed monitoring as well as conveyor belt fault detection devices – on 84 conveyors at Medupi over a span of nearly two years.

Following its success at Medupi, Tenova worked with Electrotron in 2015 to equip 74 conveyors at Kusile with Electrotron’s safety equipment.

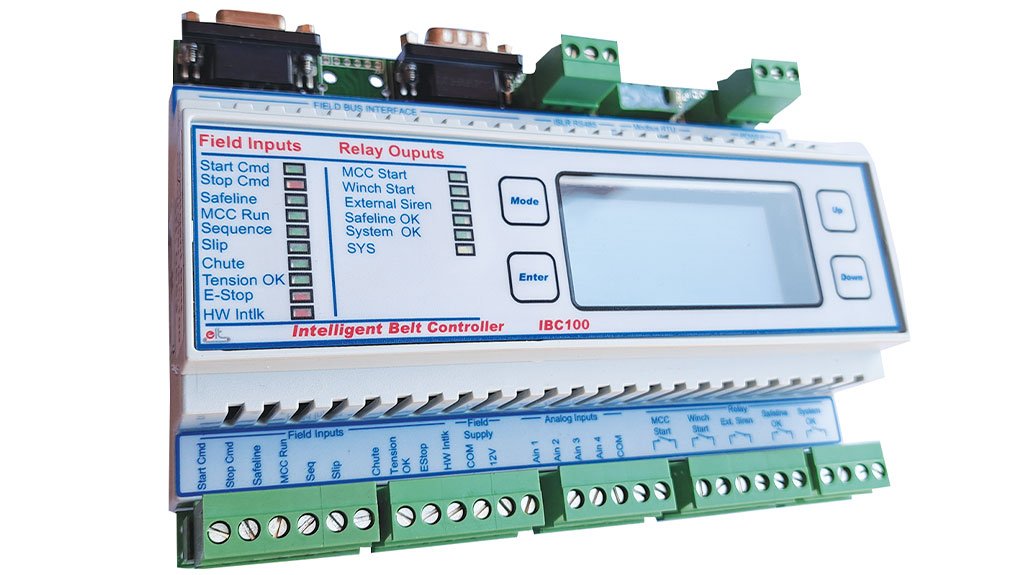

The key features of the supplied equipment include direct power distribution to all conveyor devices without requiring junction boxes or extra programmable logic controller input/output modules. All devices were able to communicate through a centralised control panel unit, with a single cable providing both power and data transmission.

The systems were designed to integrate seamlessly with the existing supervisory systems at the power stations, aligning with Eskom’s requirements for digital and analogue output registers.

This integration was part-icularly challenging owing to the tight deadlines and the power plant being in a critical project phase. Despite the rigorous demands and substantial equipment load, the systems were delivered efficiently, says Electrotron chief of operations Shane Thompson.

While the Kusile project experienced delays, resulting in some belts not being commissioned, Electrotron maintained its commitment to Eskom by securing Service Level Agreements (SLAs) for both Medupi and Kusile.

These agreements underline Electrotron’s ongoing support for Eskom’s operations, with plans to execute new orders and continue providing spare parts, particularly as the initial 15-year supply agreement with Medupi is nearing its conclusion in 2025.

The SLAs are a testament to Electrotron’s consistent service delivery and the high performance of its products. Further, the feedback that the SLAs have enabled has been instrumental in guiding the development of new products and refining strategic plans to better serve Eskom and other clients, Thompson explains.

He adds that the company’s partnership with Eskom is not solely focused on fulfilling contracts; it is also about aligning with Eskom’s strategic goals and operational requirements.

Thompson elaborates that Eskom’s control systems and safety protocols require that equipment not only meets current standards but that it can also be upgraded while remaining backward compatible.

Electrotron’s ability to produce OEM products that meet these requirements has led to its equipment being standardised across both Medupi and Kusile.

Its equipment is locally designed and manufactured, setting it apart from many other suppliers, as it not only meets technical specifications but also aligns with Eskom’s broader goals of supporting local industry and complying with national procurement regulations.

The company is committed to continuing its support for Eskom beyond 2025 with it actively developing new products that are aligned with Eskom’s evolving requirements.

One such development is the introduction of web-based, visual dashboards/ platforms, to enhance Eskom’s ability to monitor and manage its conveyor systems more effectively.

Further, Electrotron plans to introduce a new Intelligent Safe Line relay by the end of 2025. This relay will feature certified protocols and Safety Integrity Level (SIL) ratings, making it competitive in international markets and further enhancing its suitability for the local market.

Ensuring Compliance

In addition to product innovation, Electrotron is also focused on maintaining the high standards of service and support that have characterised its relationship with Eskom over the last decade. Through its commitment to safety, Electrotron is well-equipped to support Eskom in its compliance with conveyor safety regulations.

Thompson explains that conveyor safety is mandated by several regulations, including those under the Occupational Health and Safety (OSH) Act and Mine Health and Safety Act (MHSA). These laws require that any moving device must be equipped with a continuous tripping mechanism along its entire length.

Therefore, conveyors running several kilometres must have an accessible tripping device from any point along the conveyor.

Further, both the OSH Act and the MHSA require conveyors to have pre-start audio and visual warnings at strategic points. To comply, Electrotron has integrated these warnings into the pull keys along the conveyor. For instance, at every 100m interval, an LED light provides a visual alert, while a buzzer on the pull key and a siren at the conveyor’s head and tail- end – as well as at motor drive assemblies and take-up points on longer conveyors – deliver audible warnings.

This approach ensures that all warning devices are activated through a single, powered cable, adhering to legal requirements and protecting engineers and mine managers from potential liability owing to non-compliance.

Thompson adds that, measures must be in place to manage spillage from moving machinery, ensuring that it does not cause harm or damage, or lead to fires from friction. Electrotron’s systems address these legal requirements by monitoring spillage, mis-alignment and other factors.

Additionally, the regulations mandate interlocking conveyors so that a downstream conveyor does not operate if the upstream one trips, preventing overload. Electrotron’s systems include speed measurement and interlocking to manage conveyor operations effectively. For extensive conveyor lines, block chute detection and high-level stockpile detection are employed to prevent jams at the conveyor’s tail and head.

Next-Gen Safety

The significance of Electrotron’s equipment in power stations is underscored by its standardisation across Medupi and Kusile. Other power stations are now following this trend, preferring Electrotron’s equipment for upgrades and maintenance to ensure compatibility and reliability, says Thompson.

This reliability is underscored by Electrotron’s provision of reverse-compatible spare parts, facilitating smooth transitions regardless of technological advancements.

Electrotron’s systems, have enhanced safety and delivered cost savings. Moreover, the robust design, built for the harsh African environment, further differentiates the company from other suppliers.

“We want to bring Eskom to the next generation of safety, where we use advances in technology to keep workers safer, and by keeping workers safer, they can stick to their core mandate,” says Electrotron relations manager Tyrone Thompson.

These next-generation solutions comprise cutting-edge technology and are designed to address the evolving safety and efficiency requirements of modern power stations.

The upcoming products, set to launch over the next 18 months, promise enhanced processing power, faster communication and increased user-friendliness, Shane Thompson explains.

Although older products will continue to be supported until 2025, maintaining these products may become costlier, owing to the high price of niche components, he cautions.

Further, as Eskom updates and refurbishes its existing plants, there will be a need for newer technology to remain compliant and to integrate advanced features such as AI.

Shane Thompson adds that Electrotron aims to ensure that the new equipment remains compatible with existing setups, allowing for easy integration without significant changes to the existing infrastructure.

Expanding Horizons

Electrotron, now a Level 1 Black Economic Empowerment-certified company, has also completed other projects, highlighting its capability to deliver customised safety solutions across various environments.

Beyond its work with Eskom, the insert “ISO-9001-certified company” has also completed a project in Saudi Arabia involving a 14-km conveyor system equipped with dual intelligence, that has resulted in significant time-savings owing to improved efficiencies.

Additionally, Electrotron has worked with global chemicals and energy company Sasol on two major conveyors – a 29-km conveyor at the Impumelelo colliery, a 23-km conveyor at the Shondoni mine as well as a few smaller conveyors underground and in and around the plant – that have proven durable, having operated successfully for over five years thus far.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation