Energy, water efficiency key to mining sustainably in Africa

Chris Mortimer, Weir’s Director of Safety, Health & Environment in Europe, Middle East and Africa (EMEA)

The ENDURON HPGRs are used in crushing applications for fine grinding and use significantly less energy and water than traditional methods

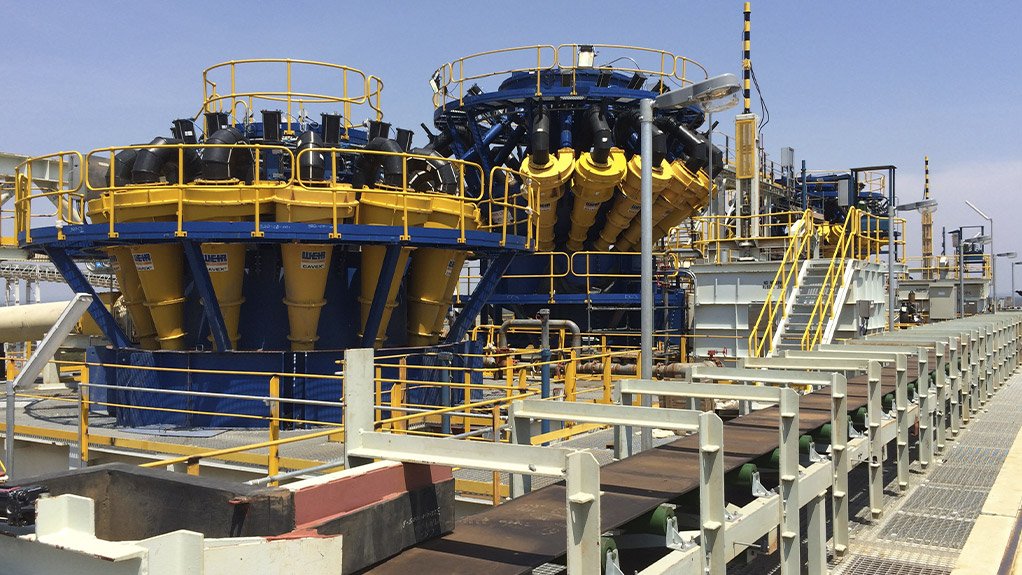

CAVEX hydrocyclones support sustainable operations by boosting efficiency and reducing water and energy use

Weir’s service centres in South Africa collect scrap metal to be used in their foundries for recycling

Weir developed Wear Reduction Technology (WRT) for both WARMAN and Envirotech pumps to boost wear life, enhancing efficiency and sustainability

This article has been supplied.

(Virtual Showroom) Achieving Weir’s ambitious sustainability goals requires active participation from every region and site across its global footprint, and Africa plays a vital role in this effort.

In fact, according to Chris Mortimer, Weir’s Director of Safety, Health & Environment for Europe, Middle East and Africa (EMEA), the continent’s limited power availability and often dry climates make it even more critical to focus on energy efficiency and water conservation.

“We understand that building a sustainable future hinges on the shift to renewable energy, and that this shift relies heavily on the supply of essential minerals and metals,” says Mortimer. “That’s why our solutions and equipment are designed to help our mining customers operate at peak efficiency, enabling them to support the global energy transition while also achieving their own sustainability goals.”

As a major contributor to the global mining sector, Weir has pledged to cut its carbon emissions by 50% by 2030. This commitment is being realised through clearly defined targets at site, regional and global levels - all aimed at using less energy, conserving water and minimising waste. In Africa, sustainability efforts include a strong drive toward renewable energy adoption, helping to reduce reliance on carbon-intensive electricity sources such as those prevalent in South Africa.

“Our most energy-intensive operations are our manufacturing plants and foundries, so we are actively working to lower their carbon footprint,” says Mortimer. “At our Isando facility, for example, we installed solar power two years ago. This not only reduces our dependence on the national grid but also enhances our operational resilience during power disruptions.”

Additional solar generation capacity is currently being installed at Weir’s Alrode manufacturing plant, south of Johannesburg, with the goal of eventually running the entire facility on renewable energy. Similarly, the company’s Heavy Bay Foundry (HBF) near Gqeberha in the Eastern Cape is also progressing toward greater reliance on renewables.

“The first phase of transitioning HBF to cleaner energy involves installing a solar generation facility,” Mortimer explains. “The second phase will introduce wind power, which we plan to procure from the second half of 2026. This will be done in collaboration with other industrial users in the region through an agreement with an independent power producer.”

Mortimer adds that community engagement is a vital part of Weir’s ESG commitments, emphasising that the wellbeing of local communities and the company are closely connected, particularly in African countries facing economic challenges. He notes that Weir’s service centres and local sites play a key role in driving community initiatives, aiming to make a positive impact wherever the company operates.

Weir Minerals Africa

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation