Ensuring the correct lubrication of worm gears

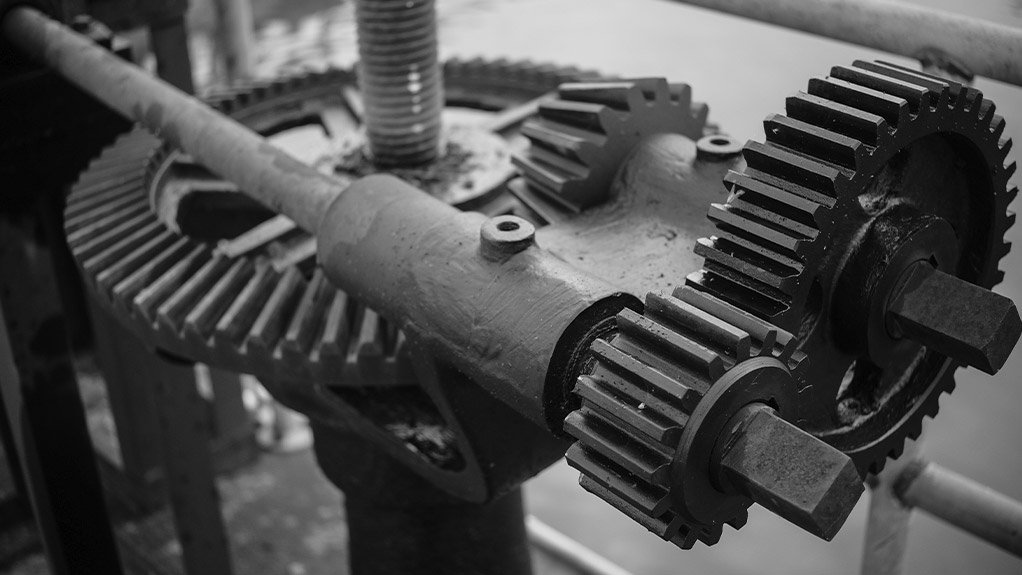

Worm gears are designed to transmit motion and power between nonintersecting shafts, such as shafts at right angles to each other, and are used in conveyor belts, industrial machinery, automation systems and various types of lifting equipment for speed reduction and when space is limited.

The specialist gears need the right lubrication to ensure they can function effectively and to extend their life span, explains Lubrication Engineers (LE) South Africa national marketing manager Gavin Ford.

There are two components in these types of gears: the worm and the worm wheel or gear. The worm is a special form of helical gear with teeth that are called threads. The worm is usually made of a hard, wear-resistant steel, while the worm wheel should be made from a good bearing bronze. However, bronze is highly sensitive to the active sulphur that is found in most extreme pressure, or EP, gear oils. Ford explains that when the bronze reacts with sulphur, the gears can get etched. This is why LE recommends avoiding lubricants that include active sulphur.

“It’s really important to choose an oil that adheres to the metal surfaces (whether the worm is above or below the wheel), provides an excellent film strength and prevents surfaces from bonding to each other from the sliding action,” says Ford.

Worm gears come in three variations, and each requires specific lubrication. The first is a cylindrical or non-throated worm gear, which is similar to a rack and pinion and has straight teeth. Ford suggests this type of gear be lubricated with a high-quality gear oil, such as LE’s Almasol vari-purpose gear lubricants.

Second is the single enveloping/throated worm gear. This has a helical cut with a parallel-sided gear mating with a concave curved worm wheel. Specialist worm gear lubricant, such as LE’s Almasol worm gear lubricant, is recommended for these types of worm gears.

The third category is the double enveloping, or double throated, worm gear. It also has a helical cut but has a curvature of both gears that increases the surface of contact between the gears.

“This can be very useful for power applications but also generates the most heat from the sliding motion,” says Ford. The constant friction in this type means only specialist worm gear lubricants should be used.

Ford says the manufacturer’s specifications can also offer helpful guidance on the right product for a specific gear.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation