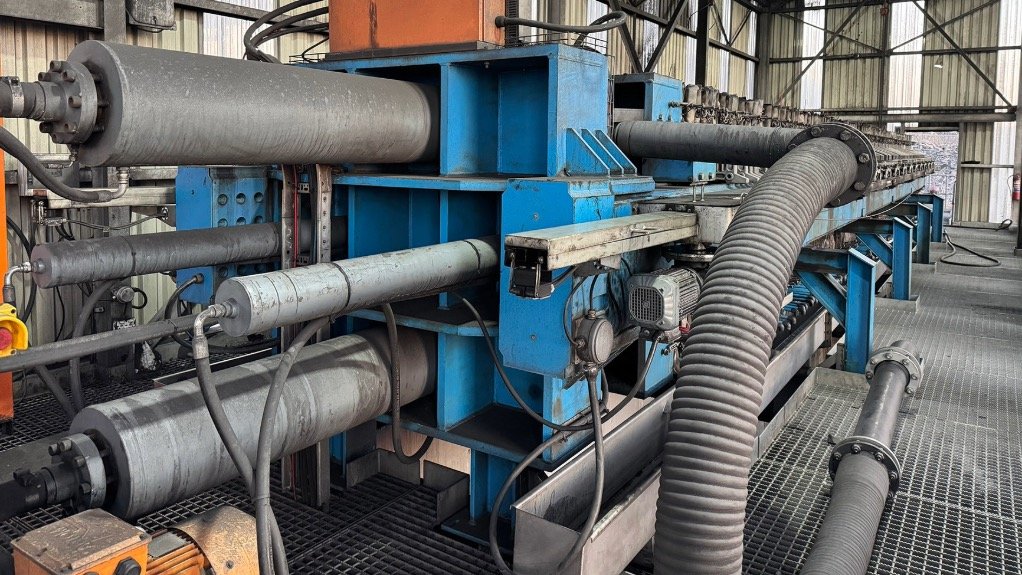

Filter press supports efficient water reuse

ENHANCED SUSTAINABILITY The filter press separates water from the solid tailings, allowing the water to be reused in the coal beneficiation process and dust suppression

UNLOCKING BENEFITS Employing a filter press efficiently processes slurry and conserves water

Employing a filter press at coal explorer and miner Canyon Coal’s Gugulethu Colliery, in Mpumalanga, has “proven to be one of the best ways to process slurry efficiently and conserve water”, says Canyon Coal COO and Gugulethu Colliery GM Jarmi Steyn.

The 40 t/h filter press is part of Canyon Coal’s commitment to ensure sustainable water use, effective water management and operational efficiency.

“This supports our overall efforts to run a sustainable operation with minimal impact on precious natural resources like water,” Steyn adds.

The processing plant – previously used at Canyon’s decommissioned Hakhano mine – was dismantled, refurbished and erected at Gugulethu. A new filter press was sourced for Gugulethu’s processing plant.

The filter press uses high-pressure dewatering technology to separate water from solid waste materials, thereby removing excess water to ensure the material can be handled using mobile equipment. The filter press receives slurry, with the fines portion of the processing spectrum that is less than 250 μm.

Once separated from the solid tailings, the water can be reused in the coal beneficiation process and for dust suppression. For the latter, a surfactant is added to ensure the conditioning of road surfaces for lower dust creation. This also assists in reducing the amount of water required for dust suppression on the roads.

Gugulethu’s water management system ensures that dirty water and clean water are always separated, allowing for the dirty water to be reused and recycled as much as possible without using additional clean water resources.

In addition to increasing water reuse and recirculation, and reducing overall fresh-water consumption, the filter press supports water conservation by reducing contamination risks, she says, adding that the filter press is effective and can meet the mine’s water requirements.

“We have a dedicated environmental team that conducts continuous monitoring, ensuring that we comply with the relevant laws and regulations,” Steyn concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation