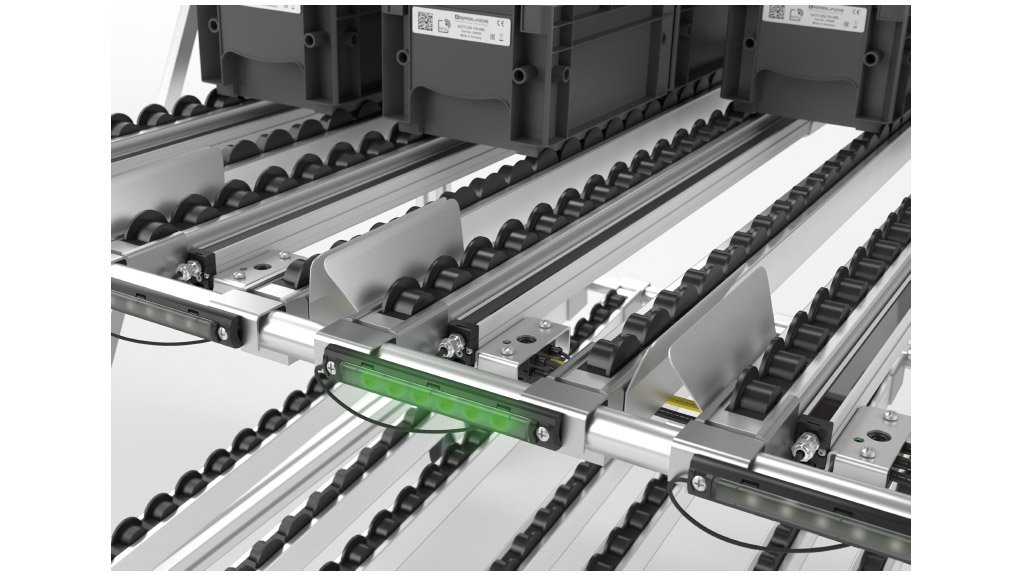

Greater Transparency and Efficiency through Complete Digitalisation in Kanban-Based Value Chains

Put-to-light LED, optical sensor rail, and lane controller as components of a digital Kanban system

This article has been supplied.

Kanban-controlled production and material flows are taken to a completely digital level with an intelligent combination of optical sensors, identification systems, and modern, process-oriented cloud software. The associated end-to-end automation means shorter replenishment lead times, improved transparency of the overall process, and increased process quality. Clean interfaces and a modular software architecture mean that the solution can be seamlessly integrated into existing IT infrastructures with ERP, MES, or WMS, or operated completely separately.

In line with the just-in-time concept of lean production, Kanban is now widely used for controlling the flow of material and information on the shop floor. However, the process is still implemented using many manual steps. Workers must transport paper cards or perform manual scans using barcode or RFID readers. An intelligent combination of optical sensors, identification systems, and modern, process-oriented cloud software takes Kanban to a completely digital level. Racks in interim storage areas and PSAs can be digitally enhanced to detect and process material movements. Because all components are user-friendly and easy to install, the solution can be integrated both into an initial design for greenfield production systems and retrofitted in existing logistics infrastructures. A fully digital Kanban management system that is created in this way provides in-depth transparency of material flows throughout production in real time. Time-consuming and error-prone manual recording of statuses is eliminated and the replenishment lead time is reduced.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation