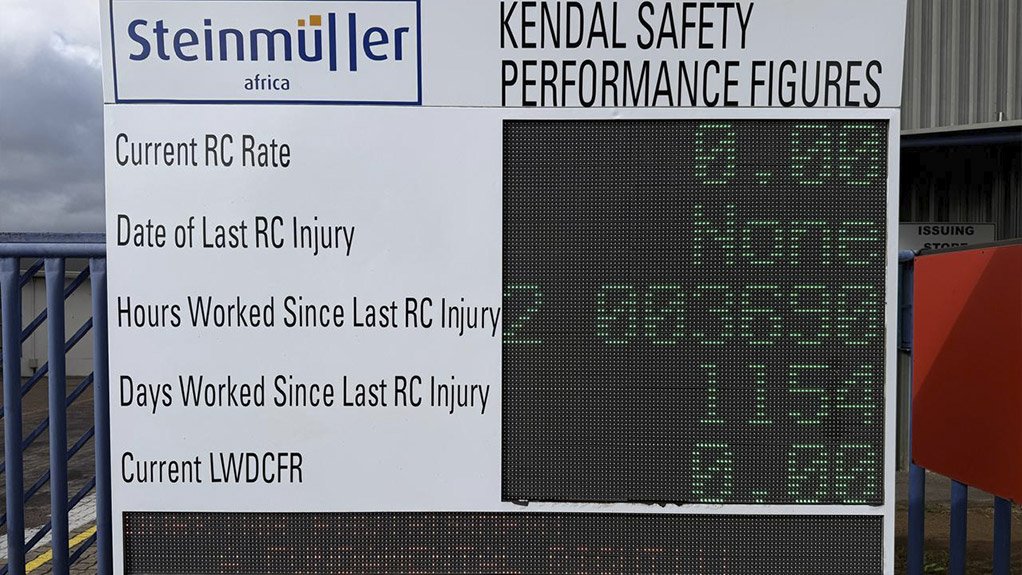

Kendal achieves 2 million hours without a Lost Time Injury (LTI)

This article has been supplied and will be available for a limited time only on this website.

Steinmüller Africa’s (SMA) team at Kendal Power Station has recorded 2 million hours (1 154 consecutive days) without a Lost Time Injury (LTI) in just over a three-year period.

This was achieved from the contract’s inception in January 2022 to February 2025, and highlights the company's strong focus on maintaining the highest safety standards.

"Workplace safety is our top priority. We value our employees and are committed to maintaining a safe, productive environment. This achievement reflects our team's dedication and sets a high standard for safety across the organisation. It’s a true testament to the hard work, vigilance, and ongoing efforts for improvement from everyone involved,” says Gift Mashamba, Kendal Project Manager.

Several factors have contributed to this achievement, including:

- Comprehensive risk assessment training for supervisors.

- VFL’s safety walks, enhancing employee engagement at their workstations.

- Daily management attendance at morning toolbox talks.

- Ongoing training on SMA safety policies and procedures, ensuring full employee understanding and adherence.

- Monthly Health, Safety, and Environment (HSE) committee meetings to maintain safety focus.

- Implementing best practices derived from similar Eskom sites to prevent repeat occurrences at the Kendal Power Station.

- Line of Fire campaign to raise awareness of safety risks.

- Brother’s Keeper campaign promoting mutual responsibility for safety.

- "No to Short-Cut" campaign to emphasise the dangers of cutting corners.

- "All Hands-on Deck" campaign fostering team collaboration for safety.

- Personal Protective Equipment (PPE) campaign reinforcing personal protective equipment usage.

- Slip, Trip, and Fall campaign to minimise common hazards on site.

Over the course of 3 years and 2 months, the team navigated a series of significant safety challenges, including working in confined spaces with potentially hazardous fumes inside boilers, interfacing with multiple service providers, and managing the integration of local, inexperienced employees. These factors posed considerable risks to safety on site.

The team also encountered several near-miss incidents that served as valuable learning experiences, including a first aid case involving a falling object, a near miss fall from height.

These incidents were addressed by reinforcing rigorous safety protocols, enhancing employee training, and conducting regular risk assessments and reviews.

“Our safety practices have been further refined to ensure that all employees fully understand the critical importance of adhering to safety procedures,” says Mashamba.

While celebrating this significant achievement, Mashamba emphasises that there is always room for improvement. To build on this success, management has implemented a range of interventions aimed at ensuring that this record is held.

SMA continues its safety training to ensure employees are aware of protocols, procedures, and regulatory updates. Regular risk assessments identify hazards, and effective risk management strategies are put in place. Routine audits and inspections ensure compliance with safety standards.

“A strong safety culture is maintained, with leadership setting an example and prioritising safety. Emergency preparedness is emphasised through regular drills and training. Continuous improvement is driven by reviewing safety policies, with employee feedback helping refine measures. This achievement demonstrates what can be accomplished when industry players take concerted and deliberate action,” says Mashamba.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation