Large Sudanese hydraulic project successfully completed

CYLINDER DELIVERY Delivery of the cylinders from Bosch Rexroth, in the Netherlands had to be coordinated with the arrival of the supporting equipment from South Africa

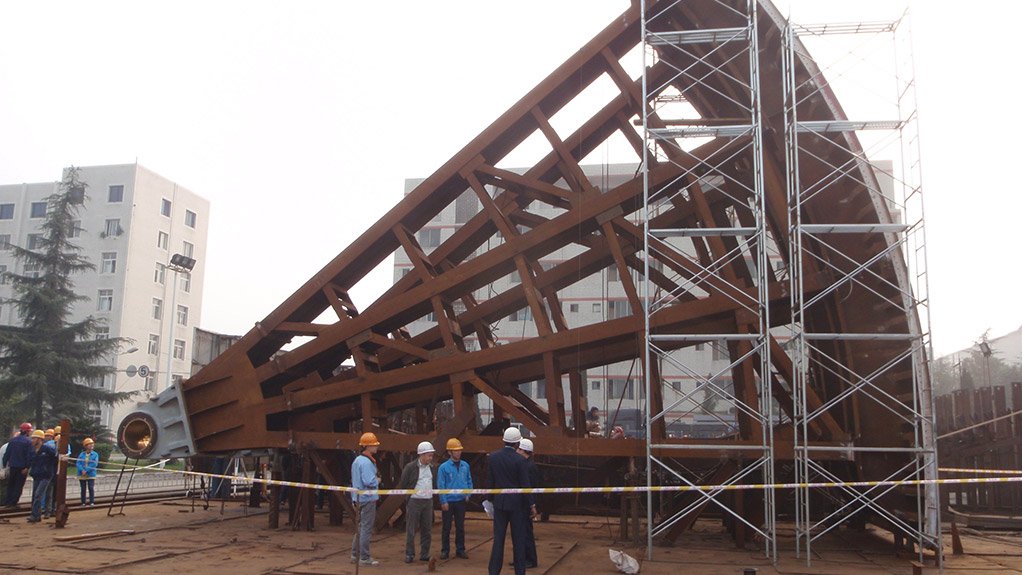

SOLID SLUICE GATES Weighing 85 t, the radial sluice gates were designed to withstand water forces of up to 4 400 t each

Fluid power technology group Hytec, completed the installation of 12 large-scale hydraulic cylinders, power packs and linkage systems to replace the hydraulic systems for controlling water flow at the Roseires dam wall on the Blue Nile, in the town Ad Damazin, in Sudan.

Hytec reports that this project, which was completed in January, was the largest single hydraulic supply and installation project it has undertaken.

The project involved about 275 t of equipment and a complete electronic control system with built-in diagnostics, with Hytec designing and manufacturing the hydraulic cylinders, power packs and linkage systems.

“Hytec got involved in the project about three years ago, through German engineering firm Bosch Rexroth, when one of the dam’s hydraulic cylinder attachment points snapped and caused a catastrophic failure of one of the dam’s radial gates,” says Hytec systems sales manager Klaus Marggraff.

He explains that, on further inspection, Australian consulting engineering company SMEC, which was the main contractor on the project, decided to replace all the hydraulic systems to significantly reduce the risk of any future failures.

“As Bosch Rexroth’s representative in sub-Saharan Africa, we managed and coordinated the design and manufacture of the cylinders by Bosch Rexroth in the Netherlands and the installation of the cylinders and electronic control solution,” Marggraff explains.

He adds that the project formed part of the dam’s planned 10 m wall-heightening project, which has brought the dam’s total capacity to six-billion cubic meters.

Weighing 85 t, the radial sluice gates were designed to withstand water forces of up to 4 400 t each.

“This meant our cylinders needed to provide a lifting force of up to 160 t to lift and control each sluice gate, and were designed with a 400 mm bore, 13 m stroke and built-in integrated measuring devices. Each cylinder weighs 13 t and, with critical planning, took three days to install by firstly lowering the ancillary equipment, followed by the cylinders, to the bottom of each gate,” says Marggraff.

He points out that Hytec installed a new mechanically articulated linkage system and supplied power packs for operating the cylinders. The system features a high degree of redundancy, enabling the cylinders to be operated by any of the five installed power packs, should a power pack not be available.

The power generation intake gates feature seven cylinders, which have 500 mm bores, 160 mm rod diameters and 7.5 m strokes with integrated positioning systems.

“Owing to the rods’ constant exposure to water, the cylinders have been covered with a stainless steel rod and a chrome layer to reduce the risk of corrosion, ensuring that no water seeps through the cylinder interface mounting plates,” Marggraff highlights, adding that Hytec supplied special interface seals to help the cylinders cope with the additional 10 m water height.

Further, he notes that the dam’s new electronic system controls the actuation of the cylinders in both the hydroelectric power plant and the deep sluice gates; therefore, Hytec had to ensure that the new electronic system controls interfaced, with the existing operating system at the power station’s own control room.

“The power plant’s gates need to be opened in a precise sequence to protect the vane inlet control mechanism for the turbines from a sudden rush of water. The radial sluice gates also need to follow a precise opening and closing procedure, as erosion and vibrations into the dam wall can become problematic if the gates are opened in an incorrect sequence or kept at incorrect positions,” Marggraff explains.

Together with local electronics manufacturing company Kulula Technologies, Hytec developed and programmed the software, using a Siemens S7 programmable logic controller to ensure the accurate positioning of the gates and the control of the nonoperating areas of the sluice gate, thereby preventing the operator from entering incorrect instructions into the control system.

“This greatly enhances the overall safety of the system and improves ease of operation. The system was further tested to safely shut the gates within the required 60 seconds,” he adds.

Moreover, Marggraff notes that all alarms and trip conditions are time-stamped for traceability, as this provides Hytec with information about potential problem areas and what additional operator training may be required.

“It also highlights any equipment misuse, which we will pick up when we perform site visits,” he says.

Overcoming Challenges

Marggraff says that daily temperatures of about 44 ºC in Sudan, overcoming the language barrier of the country, which is predominantly Arabic, and removing the original 30-year old cylinder connections from the intake gates and rigging the equipment over the completed dam wall made the project demanding.

“We also had to precisely coordinate the delivery of the cylinders from Bosch Rexroth in the Netherlands with the arrival of the supporting equipment from South Africa by shipping containers, which meant managing the permits and other logistical challenges. But we successfully completed the project and we are proud of this large-scale project,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation