Local foundries key to meeting increased demand

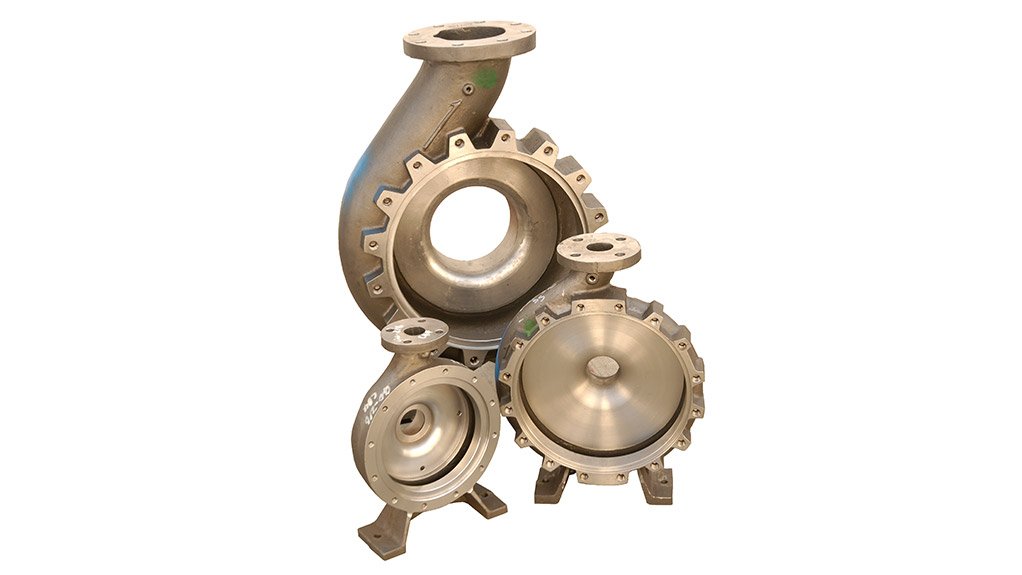

INCREASED DEMAND Foundries are expected to meet the demand for castings, which from part of valves and pumps components

As castings comprise the bulk of the cost and material of pumps and valves, local foundries play a significant part in enabling industry to reach competitiveness targets, states specialist foundry group Steloy group sales manager Leon Reeves.

Although the current foundry market suffers from the perception of producing substandard quality castings, he notes that foundries have the technical capability and ability to cater for the pending increased demand in the valves and pumps industry.

“While most foundries are currently expected to invest heavily in improvements and upgrades to align for for the impending localisation drive, Steloy Castings can demonstrate its local capacity and expertise to cater for this increase in demand,” he says.

Steloy Castings manufactures and supplies static and centrifugally cast high-alloy components to the industry.

The increase in demand for pumps and valves casting components stems from government’s valve and actuator designation policy for local procurement. The instruction notice for the designation policy was signed last month and came into effect this month. The notice requires that supplied valves in South Africa must have a 70% local content, Steloy marketing and sales director Wynand Labuschagne points out.

Engineering News reported last year that the Valve and Actuator Manufacturers Cluster of South Africa (Vamcosa) had been working with the Department of Trade and Industry and State-owned enterprises for the last three years to determine which valves should be designated and which could could not be manufactured locally, owing to the lack of local demand.

Vamcosa aims to develop the valve and actuator industry by encouraging and promoting localisation of castings, forgings and materials, which will improve job creation and skills development.

Further, Reeves points out that Steloy has the systems and processes in place to provide quality castings that are specified by manufacturers and required by the State-owned enterprises.

“We have walked the journey with Vamcosa from the beginning and are prepared to contribute to localisation initiatives for a more competitive industry,” he says.

Meanwhile, specific designation laws for the pumps industry still need to be implemented.

Currently, imported products are a key challenge for the pumps and valves industry and, thus, for the casting industry, as the local industry struggles to increase the volumes of supplied components to achieve better economies of scale, Labuschagne notes.

However, he adds that the designation policies for the valves industry are the starting point from which to increase the volumes of products produced in the industry, which, in turn, should increase local competitiveness.

These designation policies will also propel the pumps industry to use locally manufactured and supplied valves, notes Labuschagne.

As the first South African Pressure Equipment Directive-certified foundry and material supplier, Steloy Castings can produce as-cast and machined components that conform to stringent quality assurance requirements necessitated by the pump and valve industry, Reeves notes.

He adds that the group’s ISO 9001-accredited facilities in Bronkhorstspruit and Krugersdorp also provide the added assurance of superior quality and product integrity.

Further, Reeves says that, in acknowledging the major skills shortage in the technical field in South Africa, following the closure of the testing centre for trades Steloy has been appointed as decentralised trade test centre for pattern makers and moulders.

The centre is accredited by the Manufacturing, Engineering and Related Services Sector Education and Training Authority to conduct trade tests and assessments for sand moulders and pattern makers. The assessments are in line with the localisation efforts to improve the skills levels in the local manufacturing industry, he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation