Local Raise Bore Manufacturer AGC Adds Vertical Mobile Slot Borer To Portfolio

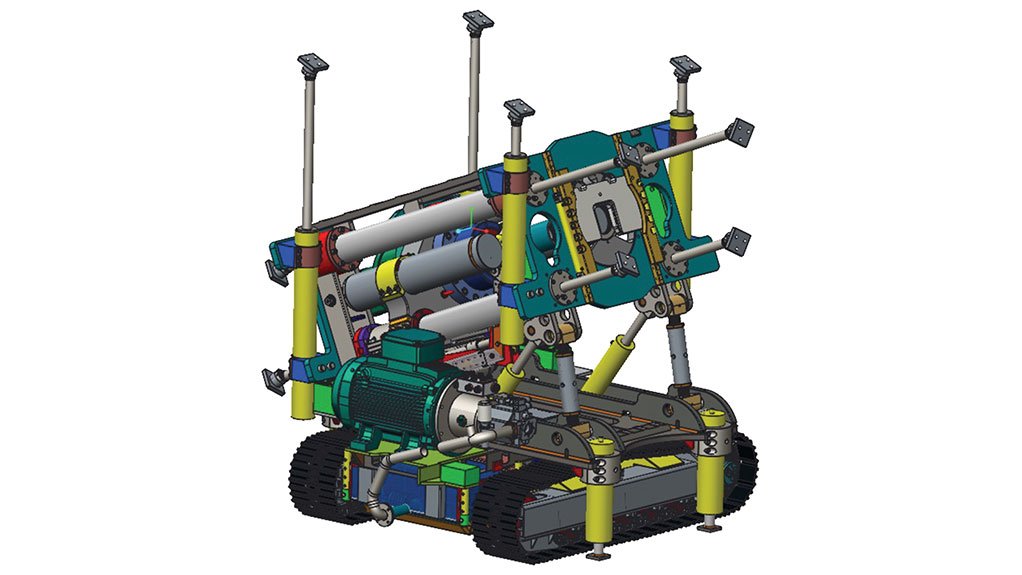

AGC Vertical Mobile Slot Borer

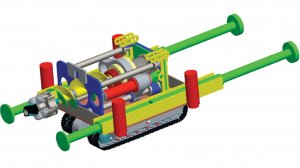

AGC MKIV SLOT / REEF EATER MKIV World’s first mobile selfrigged large diameter reef eater

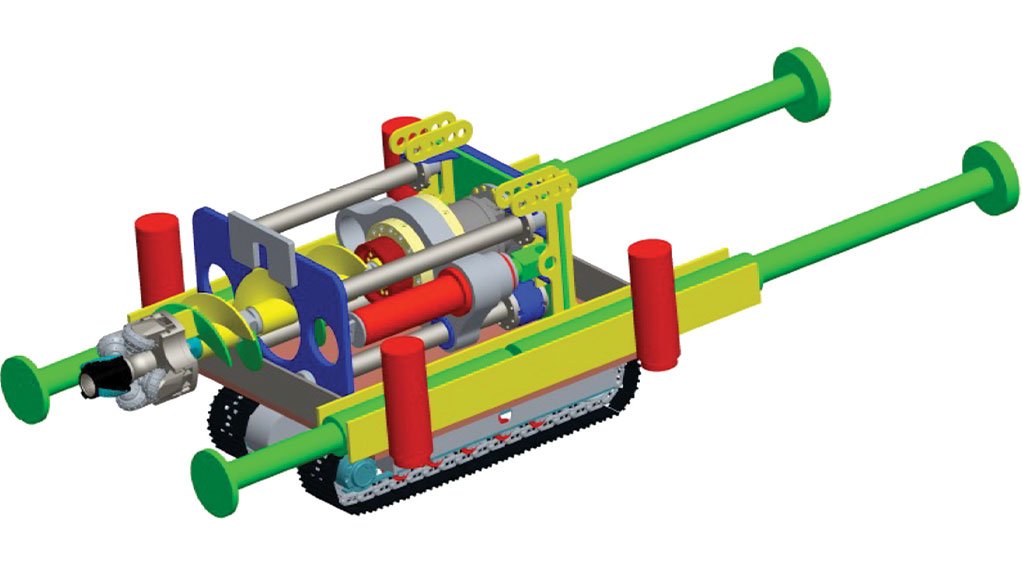

Reef Eater MK V

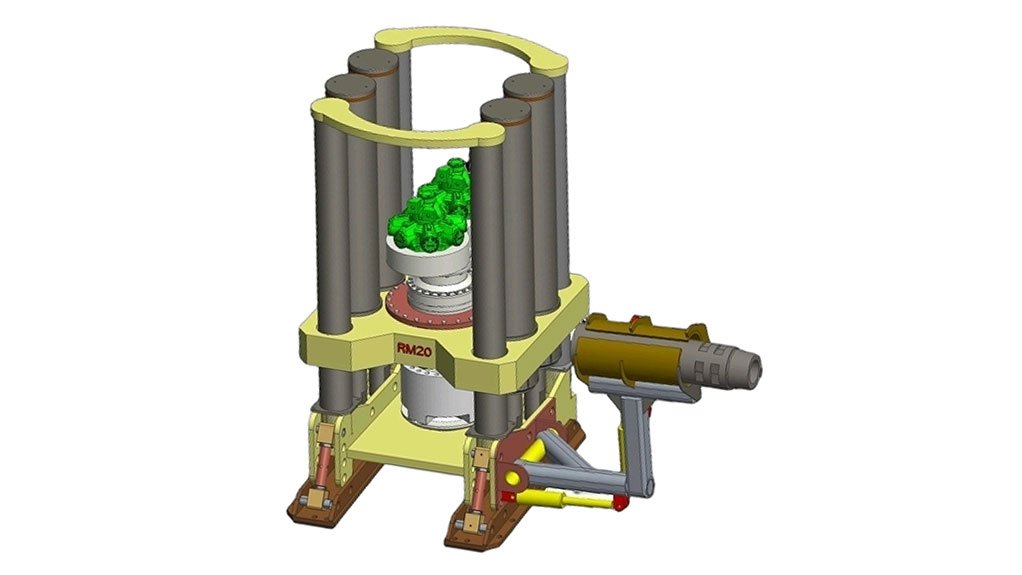

RM20 7.5M Dia Machine

Local raise bore manufacturer Atlantis Group of Companies (AGC) has showcased its latest innovation in its MK range of equipment, the AGC Vertical Mobile Slot Borer, which is best suited for block cave mining operations and is common in the diamond and copper industries.

The machine, which is the sixth machine in the MK range, complements the MK V Reef Eater and MKIV Mobile Reef Eater machines, which have been designed with the platinum and gold mining industries in mind, respectively.

The Vertical Mobile Slot Borer, like many others that the original-

equipment manufacturer offers, is a culmination of 30 years of experience as a specialist manufacturing company for mining customers, as well as CEO Sarel Smit’s experience in the mining industry.

Having worked with mining majors such as AngloGold Ashanti, Petra Diamonds, Harmony Gold, De Beers, Vedanta Zinc International and Rio Tinto in South Africa and abroad, AGC has fine-tuned its technology to be safe, efficient and easy to transport and set up.

The company is capable of bespoke product design according to customer requirements, but durability and reliability come standard with all orders.

AGC proudly holds all the intellectual property of its machines and manufactures or sources most of its components locally.

The MK range of products, in particular, helps customers to overcome drill and blast constraints that interfere with production. AGC offers regular maintenance of machines in roughly 1 000 m intervals.

Among the first users of the Vertical Mobile Slot Borer, is Palabora Mining Company (PMC), which operates the Palabora copper mine, in Phalaborwa, Limpopo.

The Vertical Mobile Slot Borer drills at a rate of about 1 m/h to bore 20-m- to 50-m-long slot raises on behalf of trackless mines using the block cave mining technique.

AGC has also worked with a mining company in India to design a RM20 7.5 m Raise Bore Machine, which is due to be shipped by the end of June.

Smit tells Mining Weekly that AGC’s customers are often involved in the design process of raise bores, citing AngloGold as an example. AngloGold worked with AGC to design and manufacture the MK IV Reef Eater, which is the world’s first mobile self-rigged, large-diameter reef eater machine.

He confirms that AngloGold had seven machines from MK 1 - MK IV Reef Eater machines, as well as other models since AGC became a trusted supplier and, often, drilling contractor for AngloGold in 2006. AGC was contracted to operate several of the machines in South Africa, until AngloGold sold its local operations to Harmony.

AGC started working with AngloGold in 2012 to research and develop a mobile self-rigged, crawler-mounted blind hole boring raise drill suitable for low dip angles.

The machine can fit into a 3 m x 3 m haulage and is transported by its own crawler assembly.

AGC is looking to supply more MK IV Reef Eater machines in South Africa for reef and slot boring applications across the country, while it aims to expand its market reach for the Vertical Mobile Slot Borer locally and internationally.

The main difference between the slot borer and reef eater machines is that the slot borer is designed to drill vertical blind holes upwards, whereas the latter could drill holes at angles varying between 20˚ and 90˚.

The MK range of machines works with a hydraulic/electric drive system, making it kinder on the environment than diesel-driven models in the market.

Depending on customer preference, the machines can be operated remotely or manually, with both options ensuring optimal safety for operators.

Smit says the company can produce these machines within four months to six months, depending on order size.

Moreover, AGC is among the few companies in the Southern Africa region offering accredited raise boring training for customers as well as graduates and independent engineers.

AGC typically offers set-up and commissioning assistance of its machines on site, before handing over the operation of machines to trained operators of the customer.

Slot boring machines have often been transported to site using a concrete foundation that had to be constructed at each site, with the machines having been bolted down using rock bolts. However, with the “mobile” introduction of design, the machine and all its auxiliary equipment can be moved on a crawler, allowing for more rapid transport and deployment.

The total cycle time for setting up boring of a 20-m-long centre hole, including down-rigging, is normally three days.

To ensure optimal operation, electricity use and maintenance of machines, AGC generates daily reports for customers using sensor technology fitted onto its machines. In a macroeconomic environment with high inflation and high input cost, cost-effective machine operation has become key.

The daily reports also ensure that customers are operating the machines safely and with due consideration to the environment.

With mining investment ticking up in Africa in pursuit of critical metals such as copper, Smit and his specialised team continue to innovate and elevate its offering to global customers in the mining industry, to solidify its position as a frontier manufacturer of raise bore equipment for the continent.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation